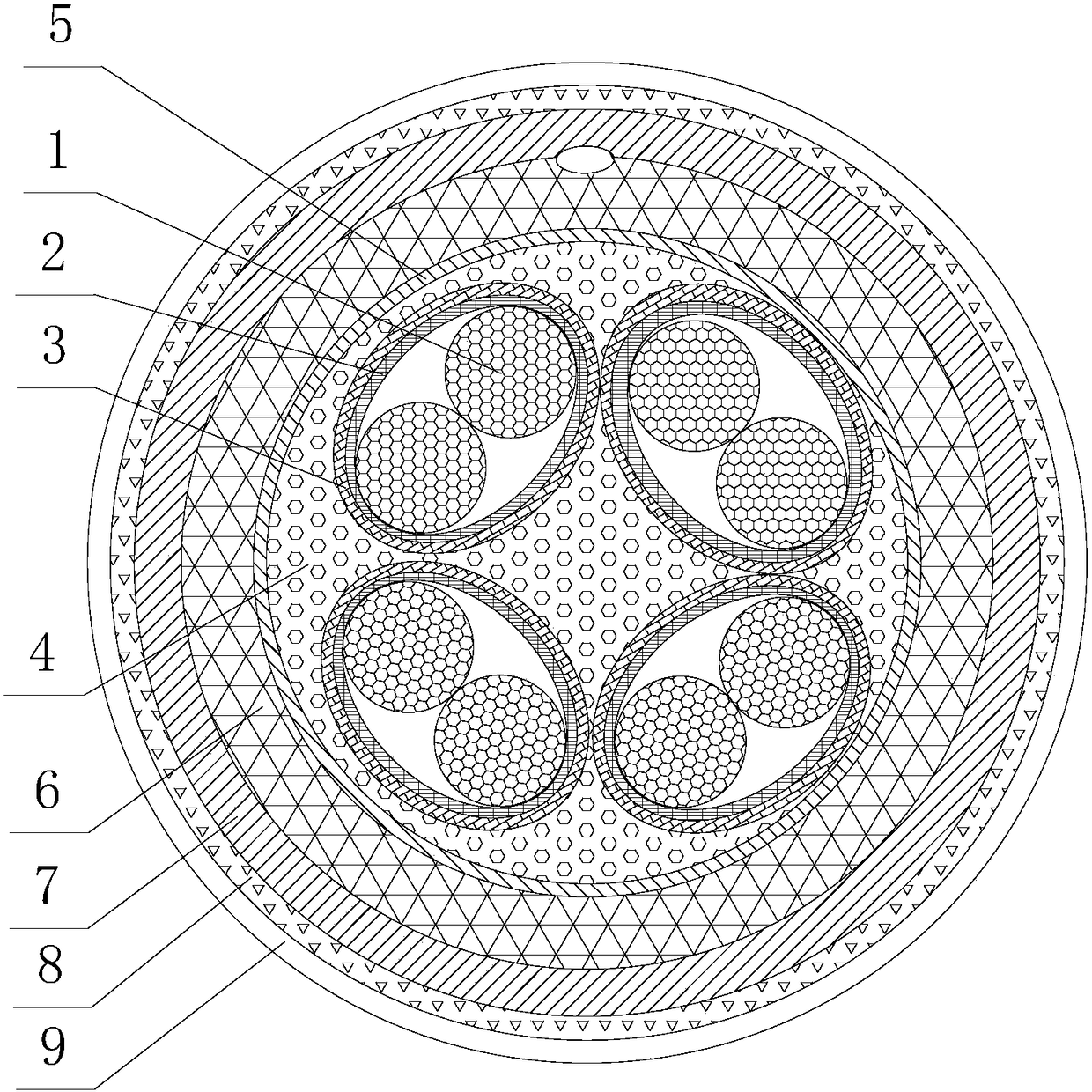

Halogen-free low-smoke flexible mineral insulated fireproof cable

A technology of insulation and fire prevention, minerals, applied in the direction of insulated cables, power cables, insulated conductors, etc., can solve the problems of inability to withstand high temperature, fire prevention, and failure to reach, and achieve guaranteed service life, good shielding effect, and stable structure solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1, the halogen-free low-smoke radiation cross-linked flame-retardant polyolefin includes the following components by mass percentage: polyurethane thermoplastic elastomer 20, POE elastomer 10, aluminum hydroxide 10, softening agent 7, polypropylene Resin 15, aluminum hypophosphite 10, zinc borate 5, ammonium molybdate 5, antioxidant 2, epoxy butyl oleate 10, carbon black 3, light calcium carbonate 3.

Embodiment 2

[0020] Example 2, the halogen-free low-smoke radiation cross-linked flame-retardant polyolefin includes the following components by mass percentage: polyurethane thermoplastic elastomer 30, POE elastomer 20, aluminum hydroxide 17, softening agent 5, polypropylene Resin 10, aluminum hypophosphite 5, zinc borate 2, ammonium molybdate 2, antioxidant 1, epoxy butyl oleate 5, carbon black 2, light calcium carbonate 1.

Embodiment 3

[0021] Example 3, the halogen-free low-smoke radiation cross-linked flame-retardant polyolefin includes the following components by mass percentage: polyurethane thermoplastic elastomer 22, POE elastomer 13, aluminum hydroxide 20, softening agent 10, polypropylene Resin 12, aluminum hypophosphite 6, zinc borate 2, ammonium molybdate 4, antioxidant 1, epoxy butyl oleate 6, carbon black 2, light calcium carbonate 2.

[0022] Compared with the prior art, the present invention has the advantages that: the conductor achieves a better effect on softness, and meets the requirements of frequency conversion; and achieves better shielding effect through the first semiconductor shielding layer provided, and The structure is stable and strong, and the durability is good. It is equipped with a halogen-free and low-smoke radiation cross-linked flame-retardant polyolefin sheath layer and an ethylene-four The vinyl fluoride copolymer resin layer makes the present invention have better charact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com