degreasing cotton machine

A technology for removing grease and cotton machine, which is applied in textile processing machine accessories, textile and papermaking, textile material processing and other directions, can solve the problems of low quality of finished cotton sheets, save work intensity, enhance stirring effect, increase The effect of flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

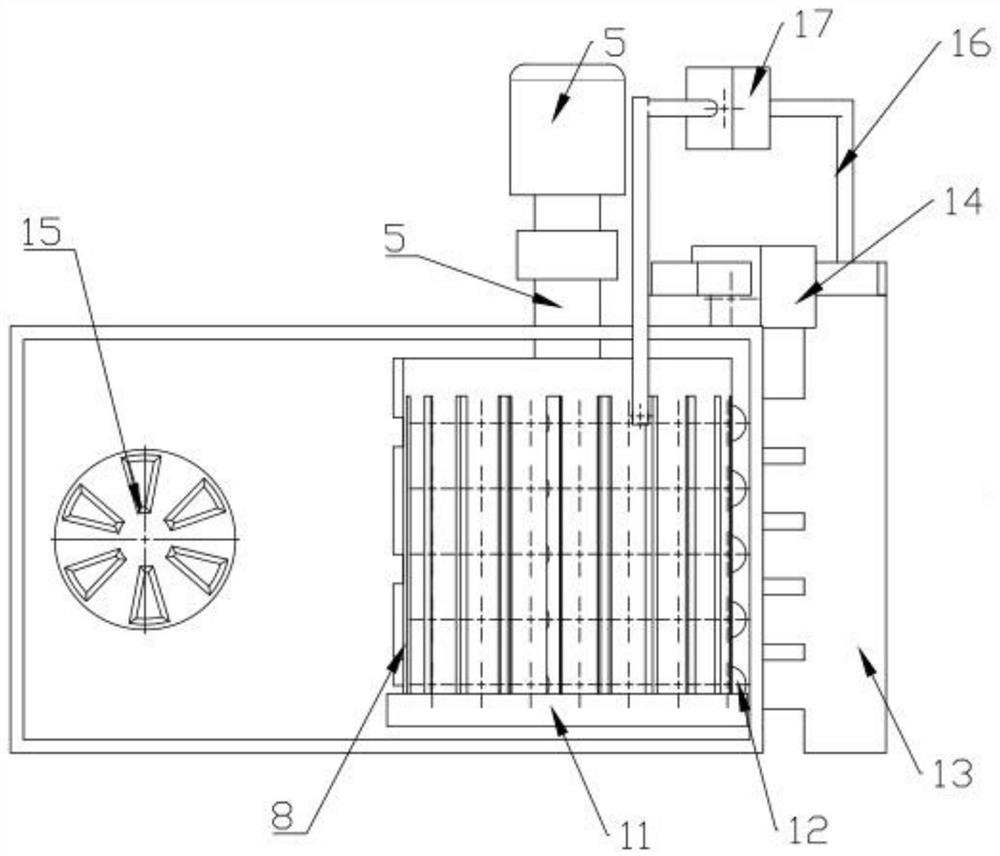

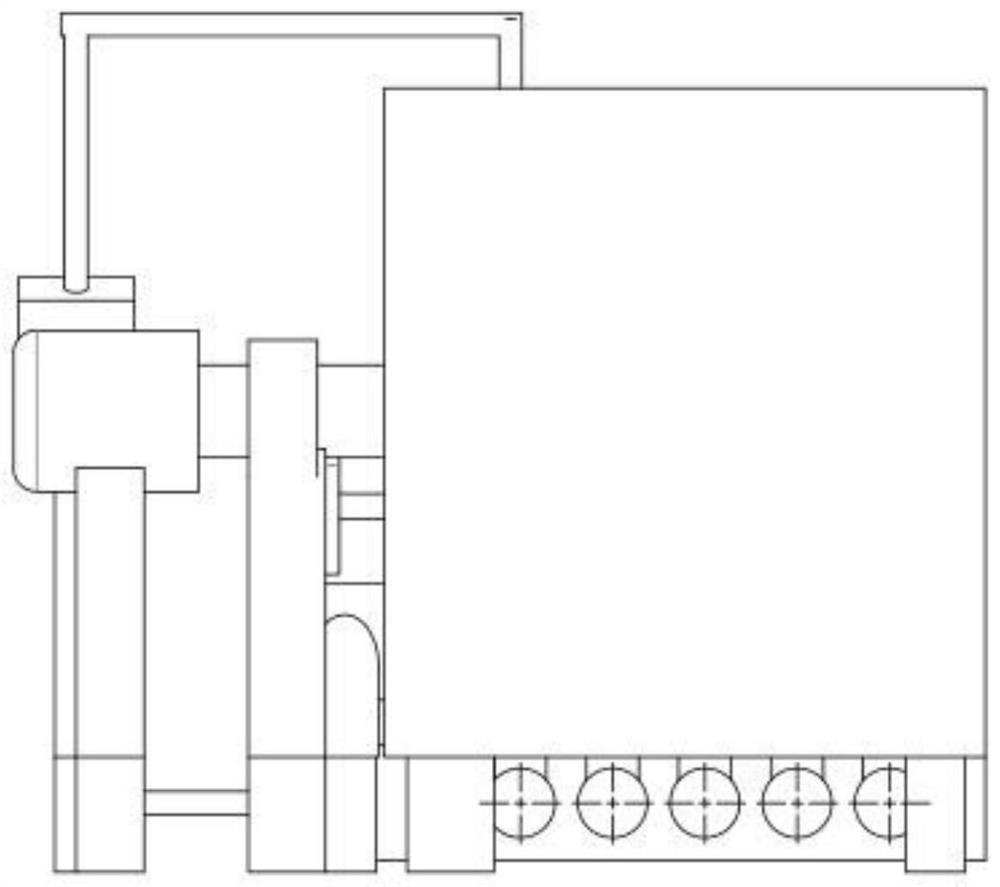

Embodiment 1

[0031] A kind of fat-removing sponge cooking machine, see Figure 1 to Figure 9 , including a housing 1, the interior of the housing 1 is divided into a rotary cooking part 2 and a vortex circulation part 3, and an extracorporeal liquid flow circulation mechanism is also provided on the housing 1, and the rotary cooking part 2 includes a rotary fixing machine arranged in the horizontal direction frame, the motor shaft connected to the rotating fixed frame is installed on the outer support frame 4 of the housing 1, one side of which is connected to the power source, the motor shaft passes through the housing 1 to transmit power to the fixed frame, and the rotating fixed frame is the opposite An open frame, with the horizontal plane as a symmetrical mirror surface, includes two semi-cylindrical hoops, each semi-cylindrical hoop includes at least 2 layers of concentric semicircular cages 9, and the distance between the cages is 5 to 25cm Between, the side of semicircle hoop close...

Embodiment 2

[0040]The principle of this embodiment is the same as that of Embodiment 1, the specific difference is that the extracorporeal liquid flow circulation mechanism is also connected in parallel with an air flow branch 16, and the air flow branch 16 includes at least two air inlets installed above the housing 1, installed on the air flow The gas pressurizing element 17 on the branch 16 and the outlet of the gas flow branch 16 are connected in parallel to the water outlet outside the casing 1 . In the specific working process, the vortex circulation part 3 can also be connected with the aeration port 18, and the aeration port 18 is connected with the airflow branch 16 or has its own airflow generation source.

[0041] The hot steam is introduced into the circulating liquid pipe after being pressurized, and flows out through the liquid outlet to form rising bubbles, which have the effect of aeration and further improve the degreasing efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com