Mechanically stirring type pulp pool

A technology of mechanical agitation and slurry tank, which is applied in textiles, papermaking, fiber raw material processing, etc., can solve the problems of inconvenient control, laborious agitation, etc., and achieve the effect of simple structure and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention but not to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

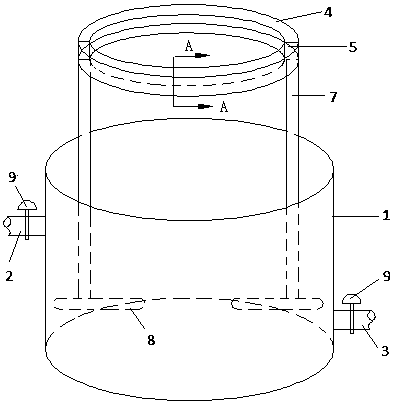

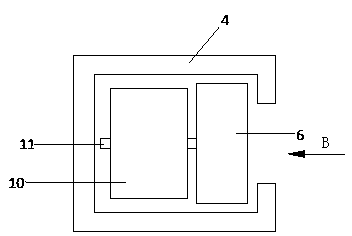

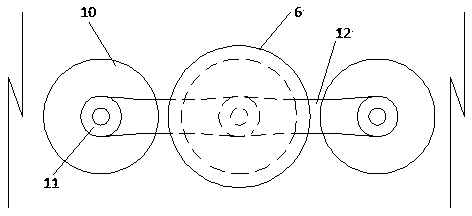

[0016] figure 1 It is a schematic diagram of the structure of the present invention. It can be seen from the figure that the present invention includes a circular tank body 1. The tank body 1 is provided with a slurry inlet pipe 2 and a slurry outlet pipe 3 with different heights. The track 4 is provided with a transmission chain 5, the transmission chain 5 is provided with two rollers 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com