Roughening device for separating cannabinoid from cannabis plants

A technology of cannabinoids and cannabis, which is applied in mixers with rotary stirring devices, transportation and packaging, chemical/physical processes, etc. demand, ensure convenience, and avoid the effect of blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

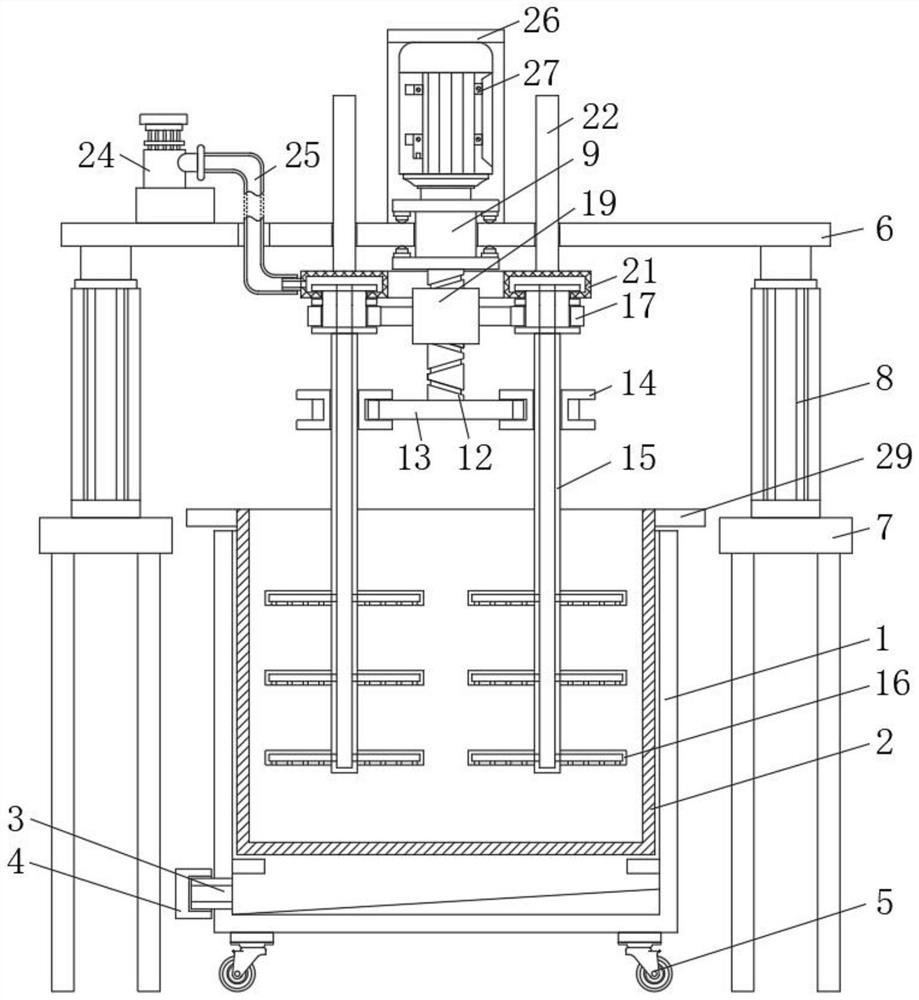

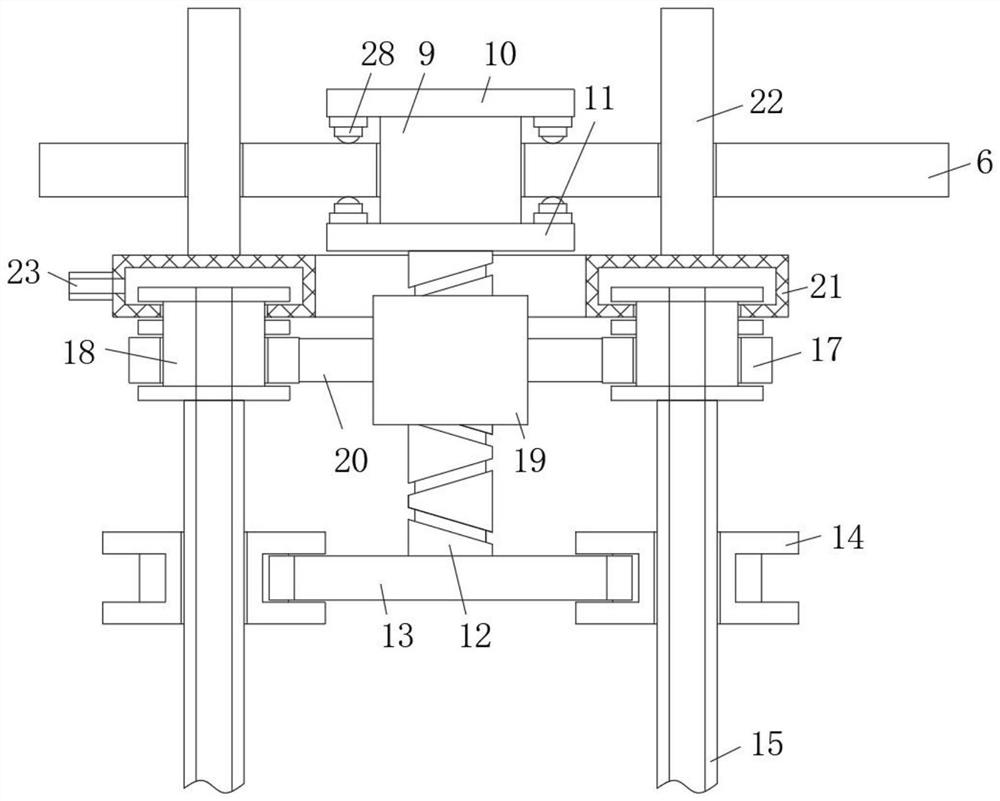

[0028] refer to Figure 1-4 , a crude device for cannabinoid separation from cannabis plants, comprising a pretreatment box 1, a lifting platform 6 is arranged vertically above the pretreatment box 1, a mounting frame 7 is provided on both sides of the pretreatment box 1, and the mounting frame 7 The top of the Z-axis cylinder 8 is fixedly installed with bolts, and the top end of the output rod of the Z-axis cylinder 8 is fixed with the bottom side of the lifting platform 6, and the middle part of the lifting platform 6 is provided with a stirring and blowing mechanism;

[0029] The lifting and lowering of the entire lifting platform 6 is realized by the Z-axis cylinder 8, and the stirring and ventilation structure of the stirring and blowing mechanism is driven into the pretreatment box 1 and the filter bag 2;

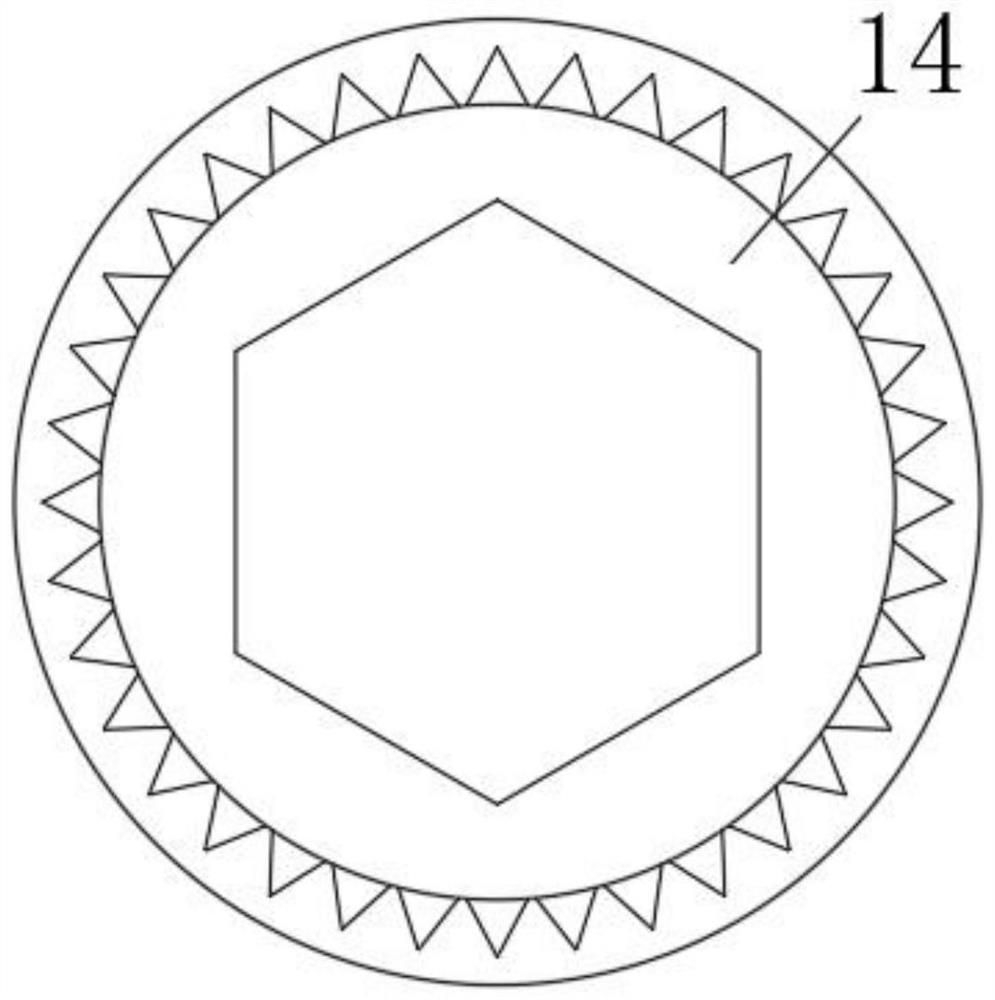

[0030] The stirring and blowing mechanism includes a circular shaft 9, a circular hole is opened in the middle of the lifting platform 6, and the circular shaft 9 pas...

Embodiment 2

[0035] like Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, a filter bag 2 is set up in the pretreatment box 1, a liquid outlet nozzle 3 is communicated with the bottom of one side of the pretreatment box 1, and the outer side of the liquid outlet nozzle 3 is covered with There is a bottom cover 4 , and several locking universal wheels 5 are evenly installed at the bottom of the pretreatment box 1 .

[0036] In this embodiment, after the extraction is completed, the bottom cover 4 is opened, the extraction liquid leaks out from the liquid outlet 3 , and the cannabis plant material waste residue is filtered out from the filter pocket 2 .

Embodiment 3

[0038] like Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the bottom end of the central axis tube 15 and the end of the stirring blade tube 16 away from the central axis tube 15 are all closed structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com