Epoxy acrylic resin flame-retarding coating and preparation method thereof

A technology of epoxy acrylic acid and epoxy acrylic acid ester, applied in the direction of fire-resistant coatings, coatings, etc., can solve the problems of application limitation, property loss, endangering people's lives and safety, etc., and achieve good finish type, strong adhesion, excellent The effect of physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

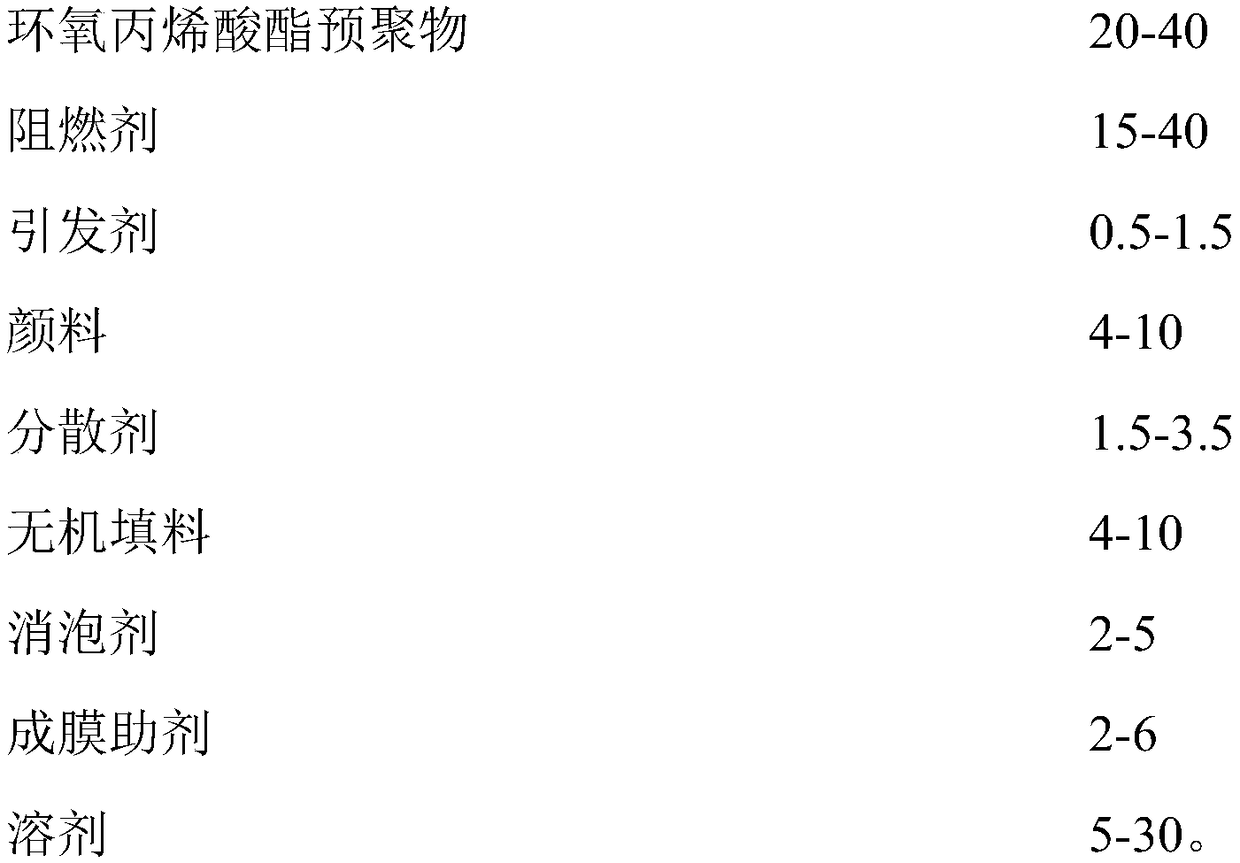

[0022] The invention provides a kind of epoxy acrylic resin flame retardant paint, by weight percentage, described paint comprises following raw material:

[0023]

[0024] The epoxy acrylate prepolymer is a polymer composed of epoxy resin and acrylate monomer, and under the conditions of nitrogen protection and stirring to the epoxy resin system, the epoxy resin system is heated to 50- Slowly add the acrylate monomer dropwise at 70°C, and control the dropping within 1-1.5h. After the dropwise addition, raise the temperature of the system to 80-90°C, react at a constant temperature for 2-3h, cool to room temperature and discharge, that is Prepare the epoxy acrylate prepolymer, wherein the epoxy resin is an alicyclic epoxy resin or an aliphatic epoxidized olefin compound or glycerol ester; the acrylate monomer is methyl acrylate And / or ethyl acrylate and / or methyl methacrylate and / or butyl methacrylate; the weight ratio of the epoxy resin to the acrylate monomer is 1-1.5:1.5...

Embodiment 2

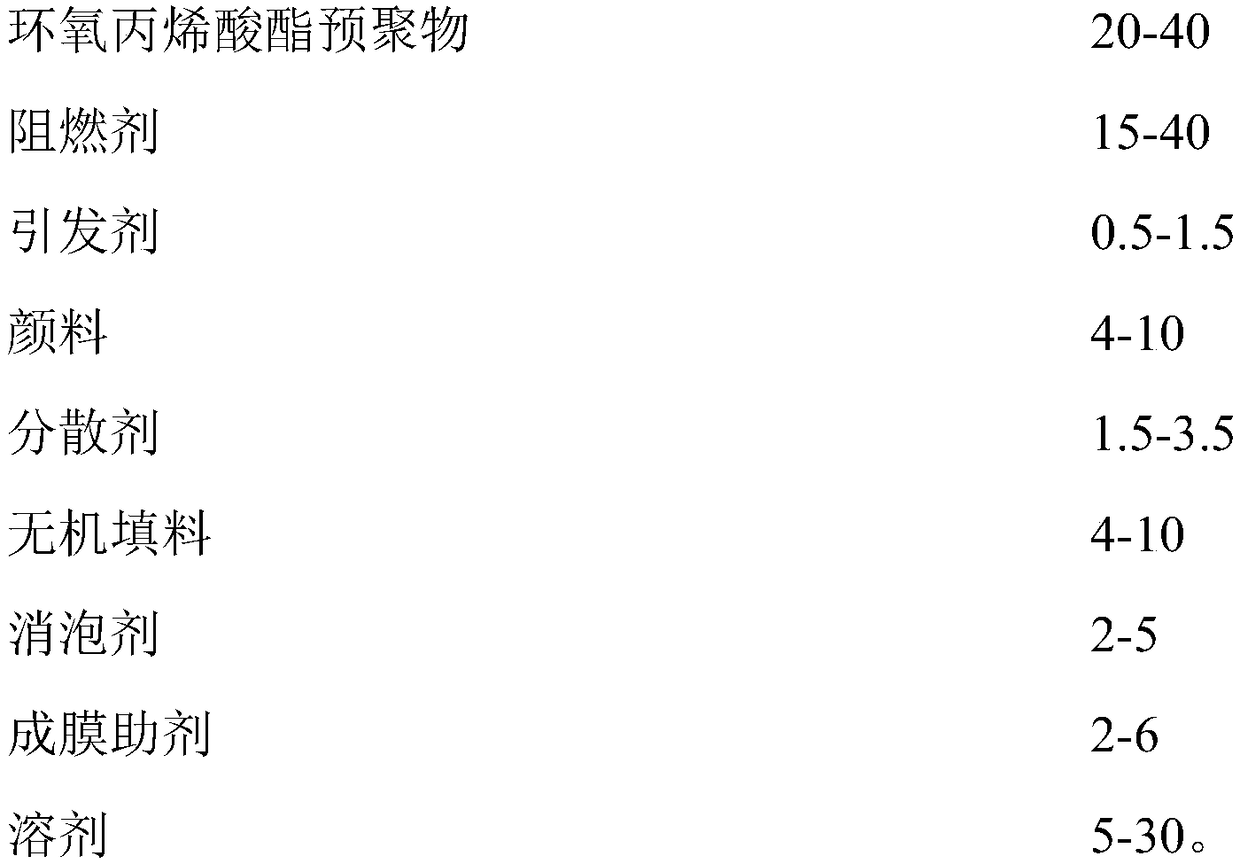

[0035] On the basis of embodiment 1, present embodiment 2 is as a preferred embodiment of the present invention, and a kind of epoxy acrylic resin flame retardant paint, by weight percentage, comprises following raw material:

[0036]

[0037] Wherein, the preparation method of the flame retardant coating is the same as in Example 1.

Embodiment 3

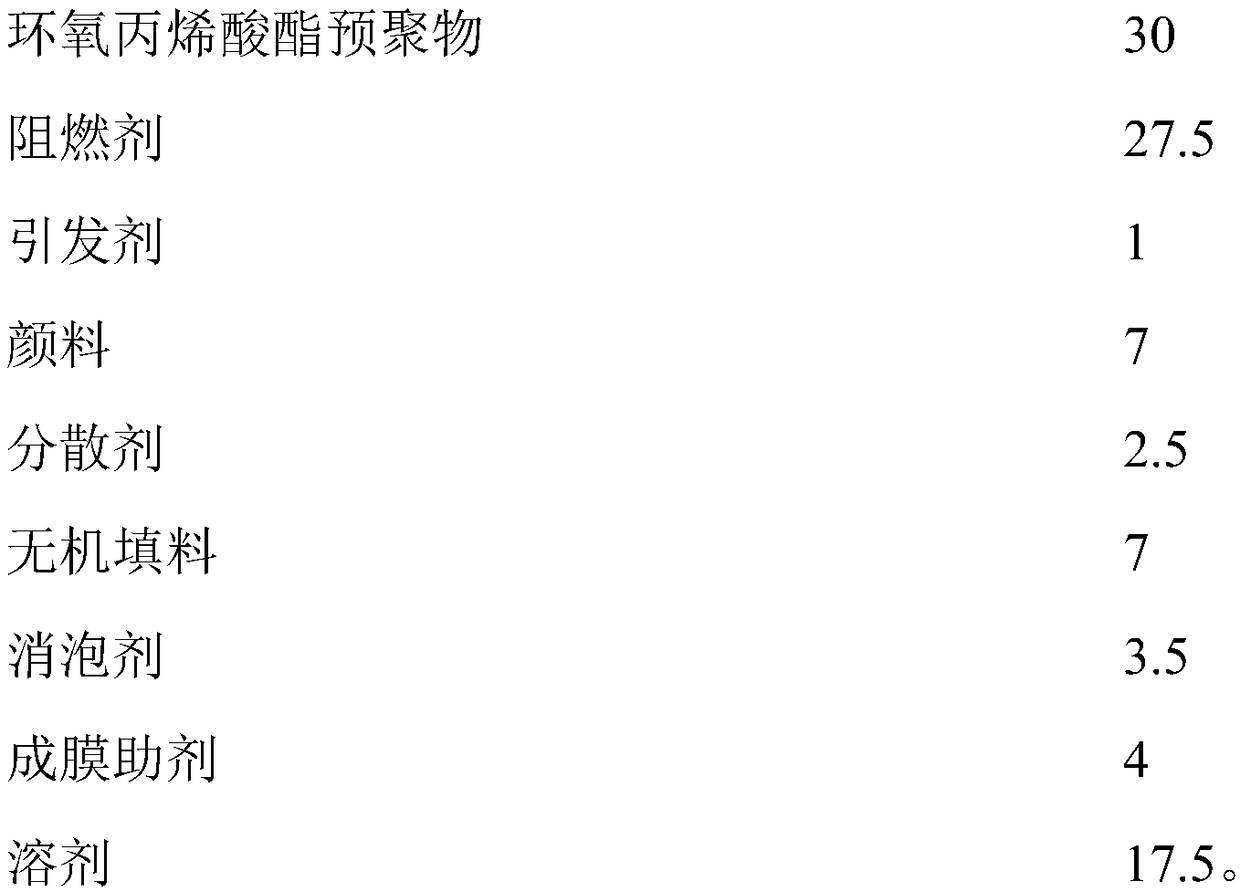

[0039] On the basis of embodiment 1, present embodiment 3 is as a preferred embodiment of the present invention, and a kind of epoxy acrylic acid resin flame retardant paint, by weight percentage, comprises following raw material:

[0040]

[0041]

[0042] Wherein, the preparation method of the flame retardant coating is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com