Preparation method of degradable starch material

A technology of starch degradation and starch milk, which is applied in the field of preparation of starch degradation materials, can solve the problems of poor mechanical properties and low water resistance, and achieve the effects of high viscosity stability, good initial viscosity, and reduced viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

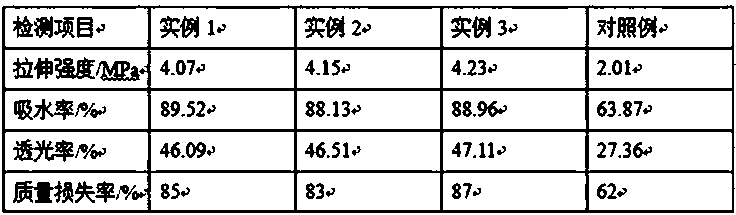

Examples

example 1

[0022] Mix starch and deionized water at a mass ratio of 2:5, stir ultrasonically for 10 minutes, adjust the pH to 3 with hydrochloric acid with a mass fraction of 3%, and obtain a starch emulsion. In parts by weight, weigh 50 parts of starch emulsion, 0.1 1 part of copper sulfate, 1 part of composite oxidizing agent, 0.2 parts of 10% sodium sulfite solution by mass fraction, mix starch emulsion, copper sulfate and composite oxidizing agent, put them into a magnet, and place them under magnetic stirring in a water bath at 45°C for 1 hour to obtain a reaction solution, drop Add a 10% sodium sulfite solution by mass fraction, let stand and cool to room temperature to obtain a suspension, filter the filter residue with suction, wash the filter residue once with deionized water, dry it in an oven at 50°C to constant weight, and cool to room temperature. Grind to get oxidized starch; by weight, take respectively 30 parts of oxidized starch, 20 parts of polylactic acid, 1 part of pla...

example 2

[0024] Mix starch and deionized water at a mass ratio of 2:5, stir ultrasonically for 15 minutes, adjust the pH to 4 with hydrochloric acid with a mass fraction of 3%, and obtain a starch emulsion. In parts by weight, weigh 55 parts of starch emulsion, 0.2 1 part of copper sulfate, 2 parts of composite oxidizing agent, 0.3 parts of 10% sodium sulfite solution by mass fraction, mix starch emulsion, copper sulfate and composite oxidizing agent, put in a magnet, and magnetically stir in a water bath at 50°C for 1 hour to obtain a reaction solution, drop Add a 10% sodium sulfite solution by mass fraction, let stand and cool to room temperature to obtain a suspension, filter with suction to obtain a filter residue, wash the filter residue twice with deionized water, dry it in an oven at 55°C to constant weight, and cool to room temperature. Grind to get oxidized starch; in parts by weight, take 37 parts of oxidized starch, 23 parts of polylactic acid, 4 parts of plasticizer, 0.5 par...

example 3

[0026]Mix starch and deionized water at a mass ratio of 2:5, stir ultrasonically for 20 minutes, adjust the pH to 5 with hydrochloric acid with a mass fraction of 3%, and obtain a starch emulsion. In parts by weight, weigh 60 parts of starch emulsion, 0.3 1 part of copper sulfate, 3 parts of composite oxidizing agent, 0.5 parts of 10% sodium sulfite solution by mass fraction, mix starch emulsion, copper sulfate and composite oxidizing agent, put them into a magnet, and place them in a water bath at 55°C for 2 hours to obtain a reaction solution, drop Add a 10% sodium sulfite solution by mass fraction, let stand and cool to room temperature to obtain a suspension, filter the filter residue with suction, wash the filter residue 3 times with deionized water, dry it in an oven at 60°C to constant weight, and cool to room temperature. Grind to get oxidized starch; in parts by weight, take 44 parts of oxidized starch, 26 parts of polylactic acid, 8 parts of plasticizer, 0.6 part of i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com