A real-time monitoring method, device and system for selective laser melting

A technology of selective laser melting and real-time monitoring, which is applied in the field of additive manufacturing to avoid molding defects and improve yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

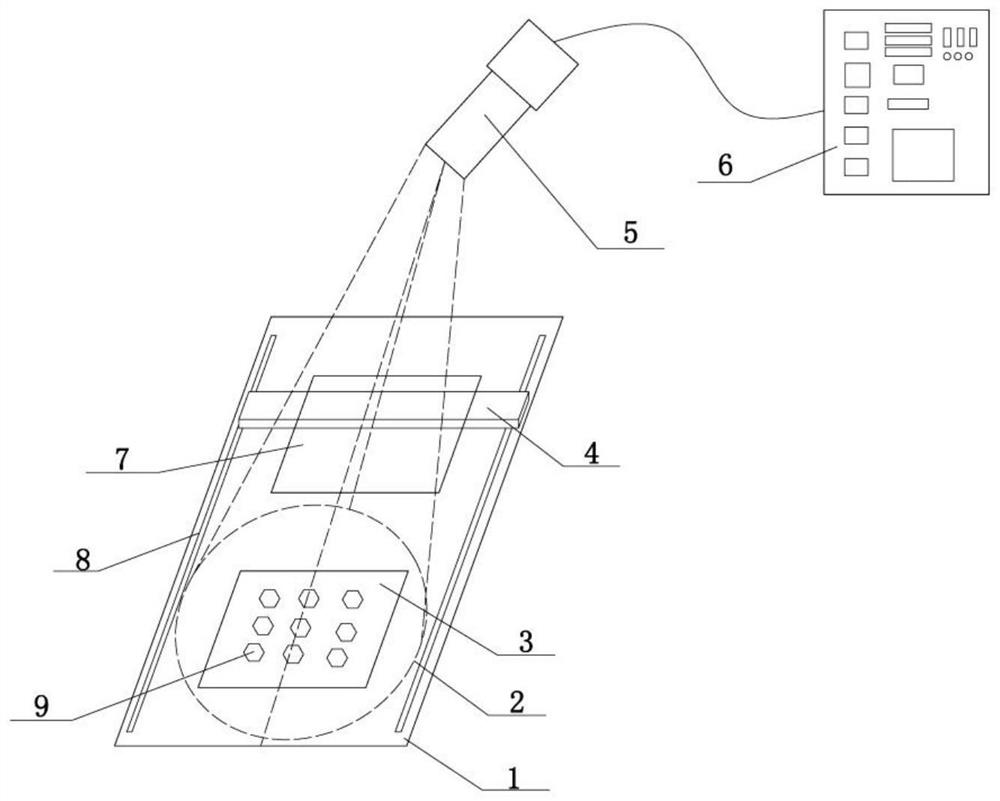

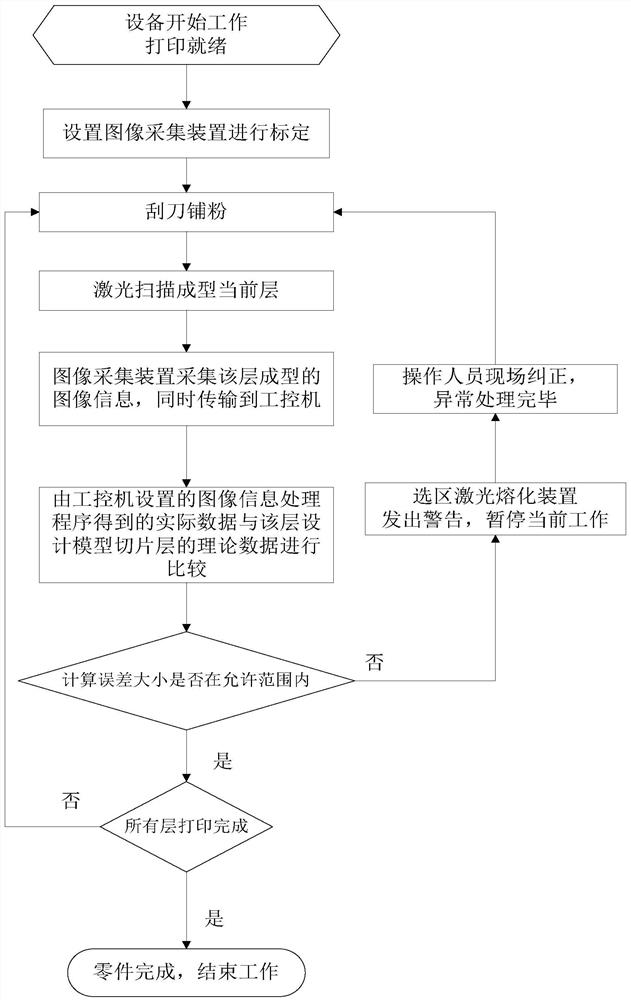

[0048] A real-time monitoring method for selective laser melting of the present invention comprises the following steps:

[0049] A1. The corner points of the calibration image are extracted to obtain the calibration parameters on the calibration board of different viewing angles, which are used to convert the molding image information into the actual data of the molding size;

[0050] A2. After the laser scans and forms a layer, collect the forming image information of the forming platform area;

[0051] A3, comparing the forming image information with the design image information, and calculating the error value;

[0052] A4. Judging the error value, if the error value is less than the set value, continue to form the next layer, and if the error value is greater than or equal to the set value, stop working.

[0053] Place the calibration board on different positions of the printing substrate, the image acquisition device acquires each corner point on the calibration board f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com