Thermal control system and thermal control method for power station in high and cold region

A technology for thermal control systems and alpine regions, applied in control/regulation systems, non-electric variable control, temperature control using electric methods, etc., can solve problems that cannot affect indoor airflow organization, aggravate energy supply contradictions in alpine regions, and actively control temperature In order to improve the rationality of heat distribution and utilization, alleviate the contradiction between energy supply and demand, and achieve efficient transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Carry out further detailed description below in conjunction with accompanying drawing:

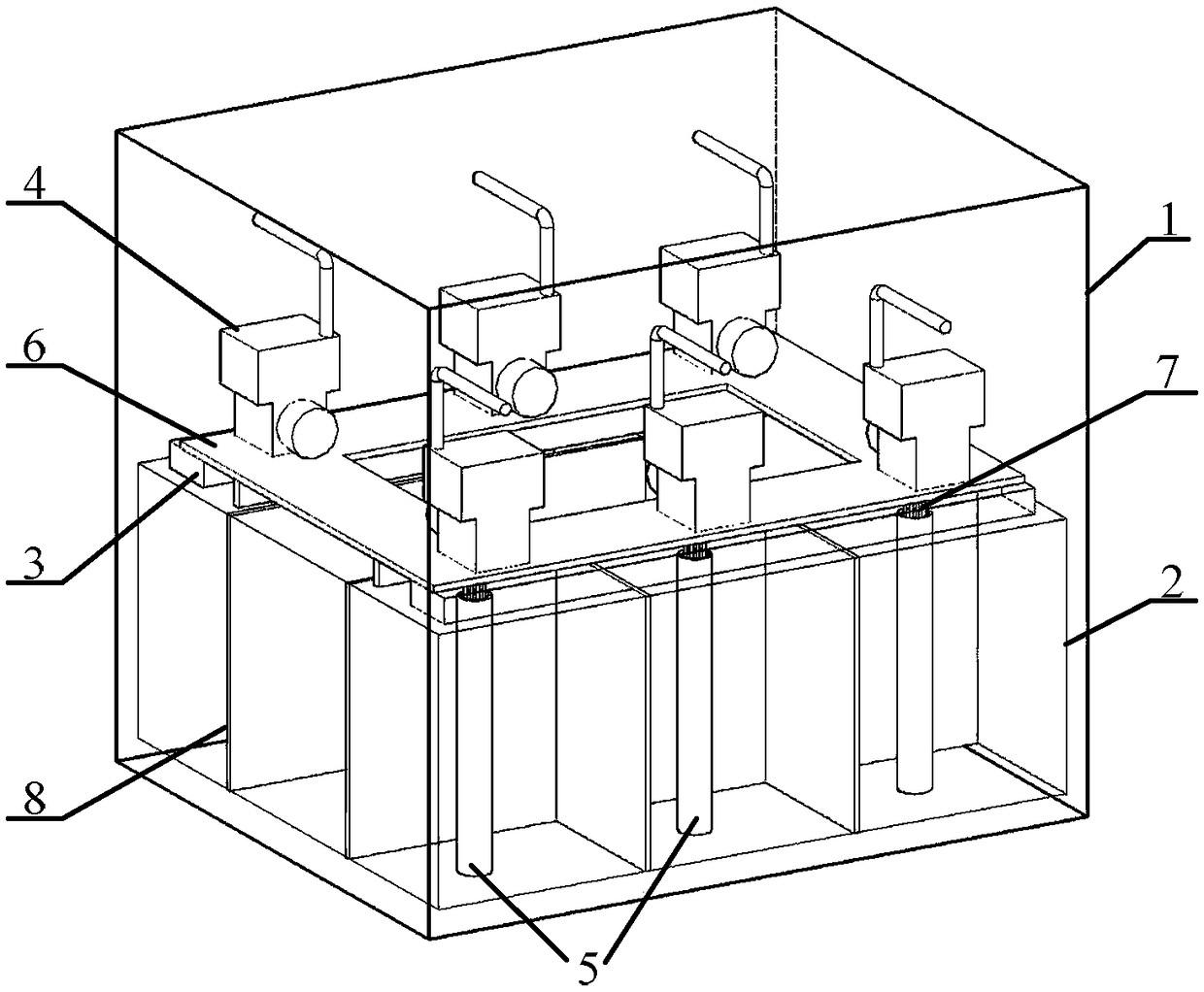

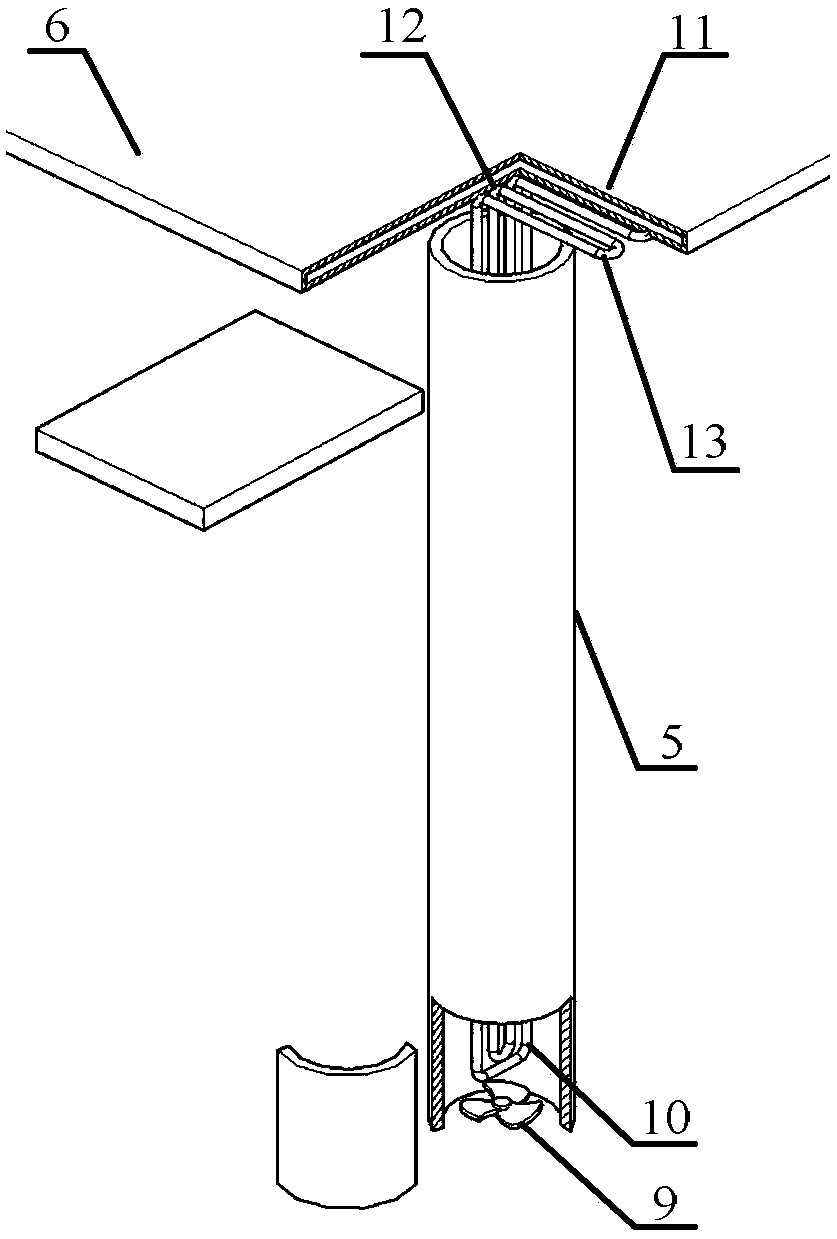

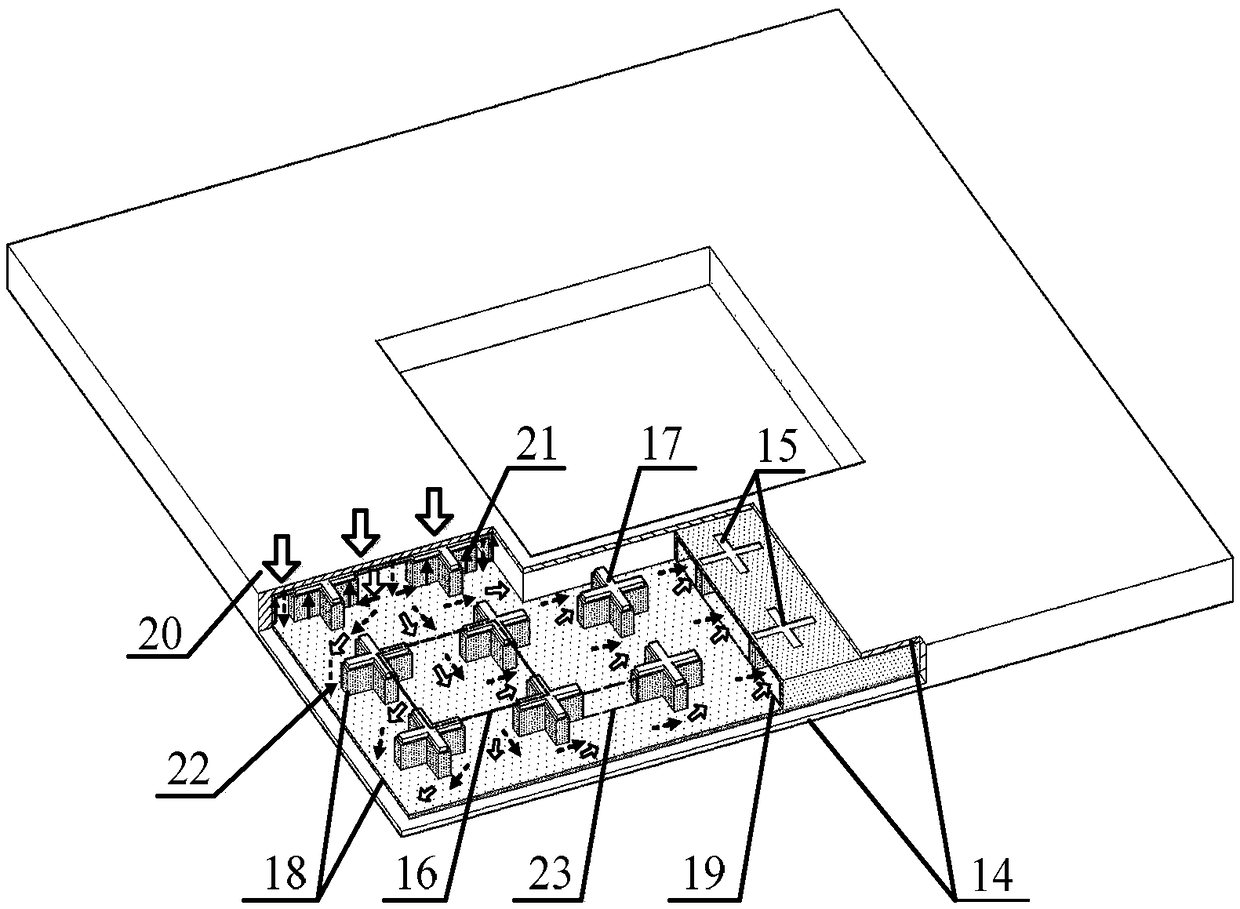

[0029] figure 1 A structural diagram of the thermal control system of a power station in an alpine region is given, including passive temperature control devices and active temperature control devices, figure 2The local details of the junction of the honeycomb structure vapor chamber and the bent loop heat pipe are given. In the power station 1, the honeycomb structure vapor chamber 6 is set as the base of the fuel-fired generator set 4 between the oil storage tank 2 containing the ventilation pipe 5 and the fuel-fired generator set. The shells are in close contact, and the honeycomb structure vapor chamber cooling section 12 is attached to the upper surface of the lubricating oil tank 3 . The bent loop heat pipe 7 is arranged under the fuel oil generating set, the bent loop heat pipe heating section 13 runs through the honeycomb structure vapor chamber cooling section, and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com