Multi-stage reducing reaming-while-drilling drilling rig and method based on radio frequency identification technology

A radio frequency identification technology, radio frequency identification technology, applied in the field of multi-stage variable diameter while drilling and reaming drilling tools, can solve the problems of difficult to accurately control the diameter of the drill hole, difficult to maintain constant pump pressure, difficult to ensure the quality of reaming, etc. Achieve the effects of reducing the comprehensive cost of drilling, easy to operate, and low drilling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

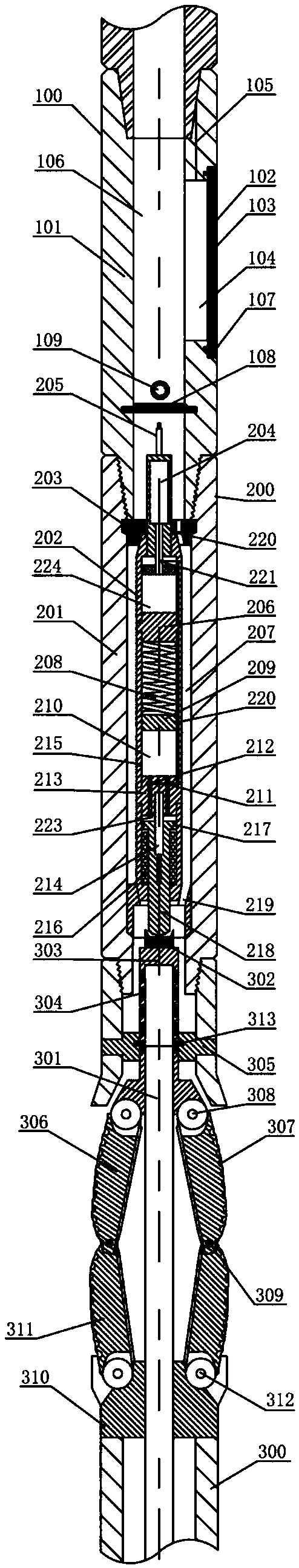

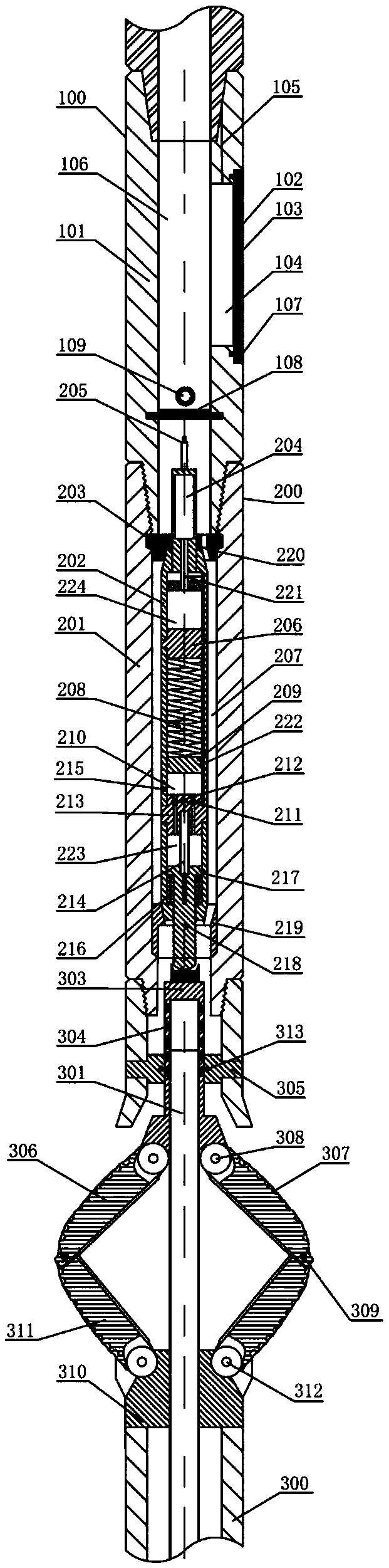

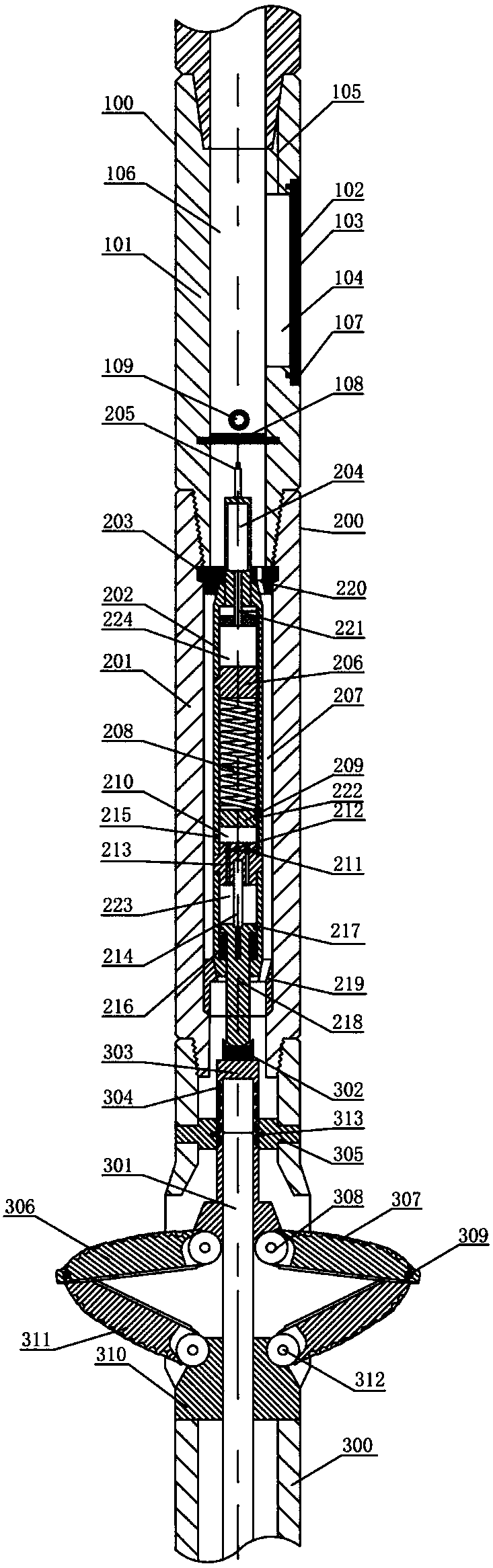

[0037] Such as Figure 1-Figure 3 As shown, the multi-stage variable-diameter reaming-while-drilling drilling tool based on radio frequency identification technology of the present invention includes sequentially connected radio frequency identification excitation mechanism 100, electro-hydraulic control mechanism 200 and multi-stage reaming recovery mechanism 300, radio frequency identification excitation mechanism 100. The electro-hydraulic control mechanism 200 and the multi-stage reaming recovery mechanism 300 are connected through threads;

[0038] Such as Figure 4 As shown, the radio frequency identification excitation mechanism 100 includes an outer shell A101, a fixed baffle A102, an O-ring A103, an RFID system 104, a transmission cable A105, a central flow channel 106, a compression screw 107, a fixed screen 108, an electronic Tag ball...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com