A kind of preparation method of copper alloy bonding wire

A technology of bonding wires and copper alloy wires, which is applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of expensive bonding wires, poor bonding performance, and easy oxidation of the surface, so as to improve oxidation resistance and corrosion resistance ability, ensuring surface gloss, and improving bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

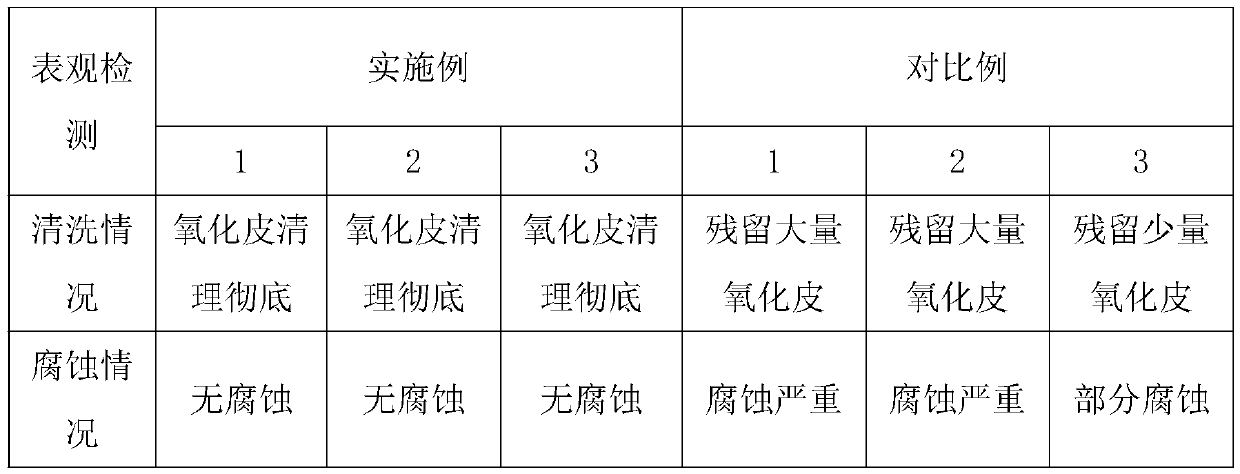

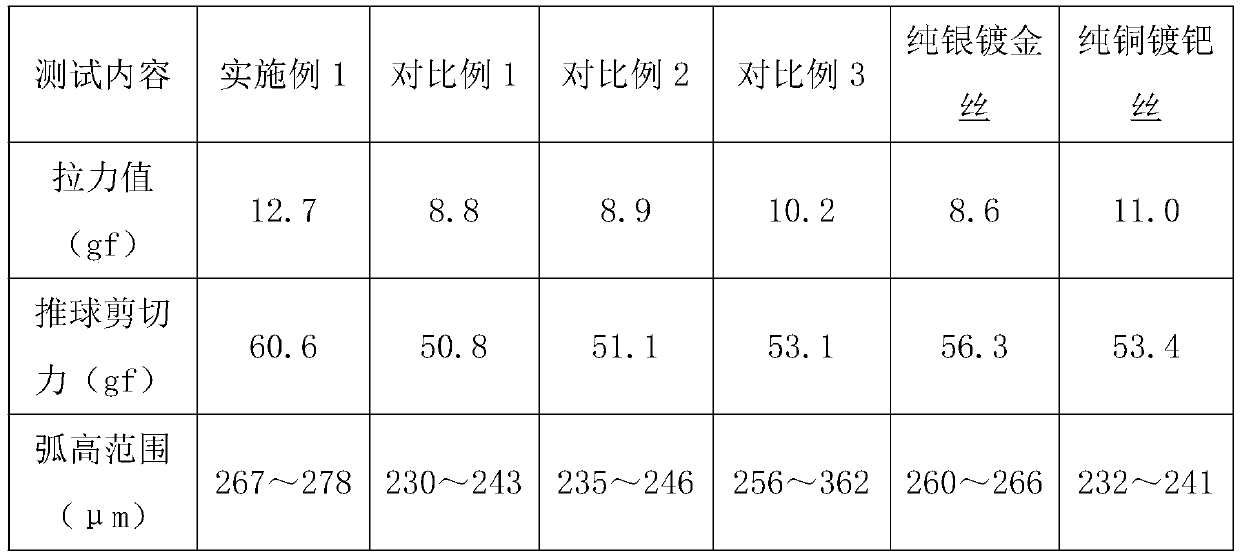

Examples

Embodiment 1

[0028] A copper alloy bonding wire proposed by the present invention, the copper alloy bonding wire uses a copper-based alloy as a substrate, the surface of the substrate is coated with a palladium layer, the thickness of the palladium layer is 0.3 μm, and the purity of palladium in the palladium layer is greater than 99.9999%, the copper-based alloy includes the following raw materials in parts by weight: 82 parts of copper, 2 parts of silver, 0.4 part of magnesium, 0.2 part of gold, and 1 part of cerium;

[0029] The preparation method of copper alloy bonding wire: comprises the following steps:

[0030] S1. Pretreatment of raw materials: select copper ingots and silver ingots, wash them with a 5% sodium hydroxide aqueous solution, then wash them with deionized water, and dry them to complete the pretreatment of copper ingots and silver ingots;

[0031] S2, preparation of alloy billet: prepare raw materials according to the weight of 82 parts of copper, 2 parts of silver, 0....

Embodiment 2

[0044] A copper alloy bonding wire proposed by the present invention, the copper alloy bonding wire uses a copper-based alloy as a substrate, the surface of the substrate is coated with a palladium layer, the thickness of the palladium layer is 0.4 μm, and the purity of palladium in the palladium layer is greater than 99.9999%, the copper-based alloy includes the following raw materials in parts by weight: 85 parts of copper, 3 parts of silver, 0.6 part of magnesium, 0.3 part of gold, and 2 parts of cerium;

[0045] The preparation method of copper alloy bonding wire: comprises the following steps:

[0046] S1, pretreatment of raw materials: select copper ingots and silver ingots, wash them with a 7% sodium hydroxide aqueous solution, then wash them with deionized water, and dry them to complete the pretreatment of copper ingots and silver ingots;

[0047] S2. Preparation of alloy billet: prepare raw materials according to the weight of 85 parts of copper, 3 parts of silver, 0...

Embodiment 3

[0060] A copper alloy bonding wire proposed by the present invention, the copper alloy bonding wire uses a copper-based alloy as a substrate, the surface of the substrate is coated with a palladium layer, the thickness of the palladium layer is 0.6 μm, and the purity of palladium in the palladium layer is greater than 99.9999%, the copper-based alloy includes the following raw materials in parts by weight: 88 parts of copper, 4 parts of silver, 0.8 parts of magnesium, 0.5 parts of gold, and 3 parts of cerium;

[0061] The preparation method of copper alloy bonding wire: comprises the following steps:

[0062] S1. Pretreatment of raw materials: select copper ingots and silver ingots, wash them with an aqueous solution of sodium hydroxide with a mass concentration of 8%, then wash them with deionized water, and dry them to complete the pretreatment of copper ingots and silver ingots;

[0063] S2, the preparation of alloy billet: prepare raw material according to weight 88 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com