Australian C-320 asphalt and production method thereof

A C-320 and bitumen technology, which is applied in the Australian C-320 bitumen and its production field, can solve the problems of losing the bitumen export market, failing to meet the requirements of bitumen quality indicators, and being unable to export bitumen products, etc., and achieving a simple and easy production process. The effect of obtaining and enhancing export competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

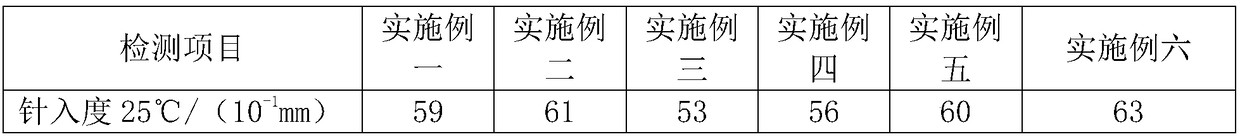

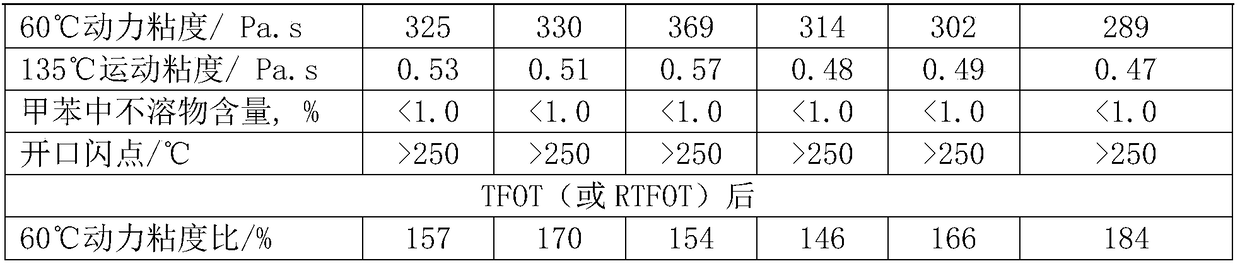

Embodiment 1

[0033] (1) After heating 100 parts by mass of vacuum residue to 150°C, inject it into an asphalt mixing tank, and perform mechanical stirring at 150°C.

[0034] (2) The 60°C dynamic viscosity index of the vacuum residue oil was detected, and the detected value of the 60°C dynamic viscosity index of the vacuum residue oil was 466 Pa.s.

[0035] (3) Inject 5 parts by mass of the extracted oil into an asphalt blending tank and perform mechanical stirring and blending with the vacuum residue at a temperature of 150° C. for 6 hours.

[0036] (4) After the mixing and blending is completed, the finished product is put into an asphalt storage tank for storage at a storage temperature of 120°C, and it will leave the factory within 15 days of storage.

[0037] The vacuum residue in this example is produced by mixing Iranian heavy crude oil and Egyptian Belayim crude oil at a ratio of 9:1 and then deep-drawing through a 10 million-ton atmospheric and vacuum distillation device, with a pe...

Embodiment 2

[0040] (1) After heating 100 parts by mass of vacuum residue to 150°C, inject it into an asphalt mixing tank, and perform mechanical stirring at 150°C.

[0041] (2) The 60°C dynamic viscosity index of the vacuum residue oil was detected, and the detected value of the 60°C dynamic viscosity index of the vacuum residue oil was 473Pa.s.

[0042] (3) Inject 5 parts by mass of the extracted oil into an asphalt blending tank and perform mechanical stirring and blending with the vacuum residue at a temperature of 150° C. for 6 hours.

[0043] (4) After the mixing and blending is completed, the finished product is put into an asphalt storage tank for storage at a storage temperature of 120°C, and it will leave the factory within 15 days of storage.

[0044] The vacuum residue in this example is produced by blending Saudi medium crude oil and Colombian Castile crude oil at a ratio of 3:1 and then deep-drawn through a 10 million-ton atmospheric and vacuum distillation unit, with a penet...

Embodiment 3

[0047] (1) After heating 100 parts by mass of vacuum residue to 145°C, inject it into an asphalt mixing tank, and perform mechanical stirring at 145°C.

[0048] (2) The 60°C dynamic viscosity index of the vacuum residue oil was detected, and the detected value of the 60°C dynamic viscosity index of the vacuum residue oil was 369 Pa.s.

[0049] (3) Continue to mechanically stir the vacuum residue at a temperature of 145° C. for 1 hour.

[0050] (4) After the mixing and blending is completed, the finished product is put into an asphalt storage tank for storage at a storage temperature of 120°C, and it will leave the factory within 15 days of storage.

[0051] The vacuum residue in this example is produced by blending Iranian heavy crude oil and Egyptian Belayim crude oil at a ratio of 9:1 and then deep-drawing through a 10 million-ton atmospheric and vacuum distillation unit, with a penetration of 531 / 10mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

| Penetration | aaaaa | aaaaa |

| Penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com