Method of utilizing tungsten powder and nickel powder as raw materials to prepare superfine tungsten carbide powder

A technology of tungsten carbide and tungsten powder is applied in the field of preparing ultra-fine tungsten carbide powder, which can solve the problems of complex process flow, long crushing time, affecting powder properties, etc., and achieve the effect of promoting bonding reaction, shortening reaction time and high industrial value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

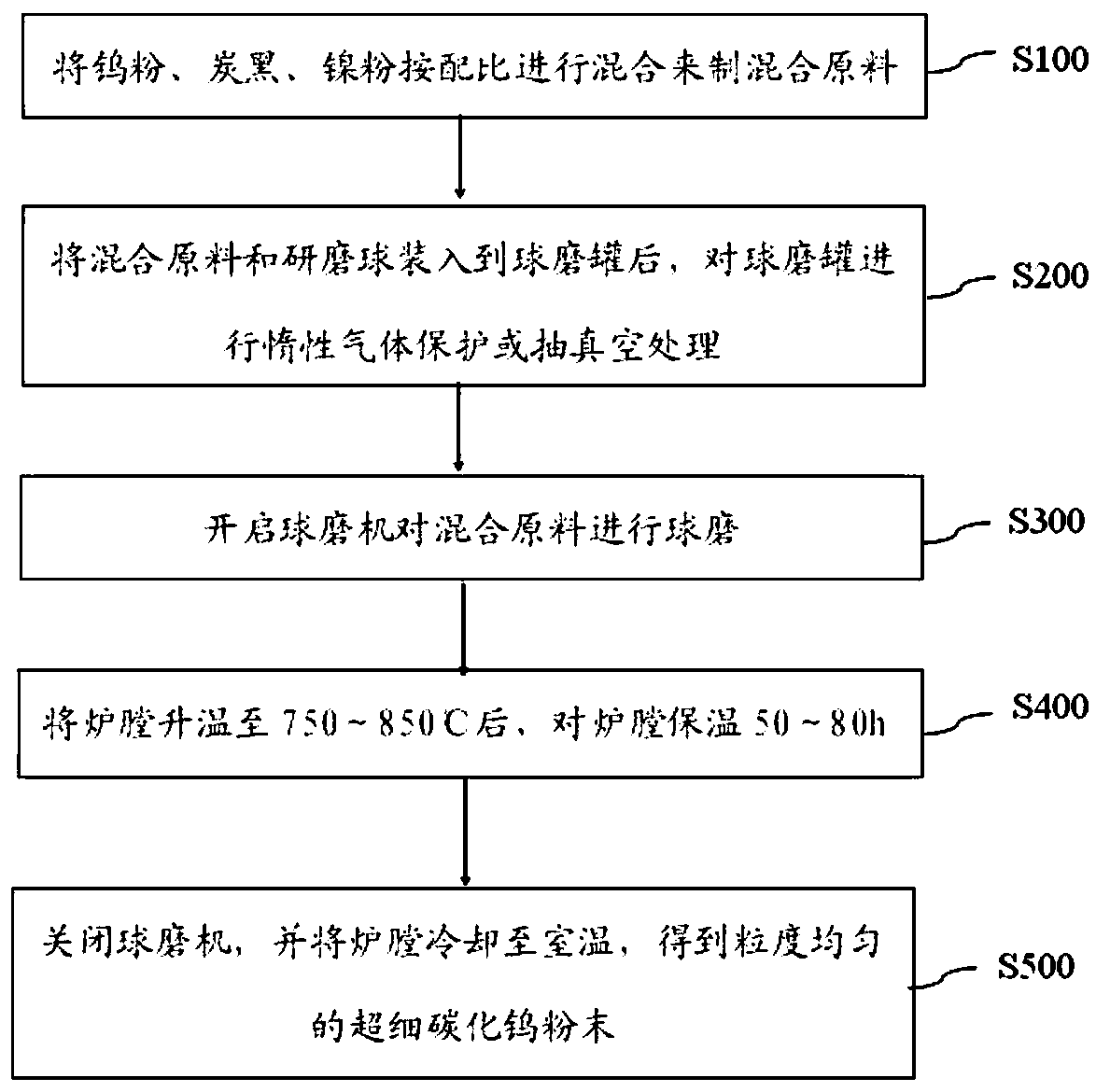

[0033] A method for preparing superfine tungsten carbide powder with tungsten powder and nickel powder as raw materials, comprising:

[0034] (1) 90g tungsten powder, 7.2g carbon black and 6g nickel powder are mixed to be mixed with mixed raw materials;

[0035] (2) Put the mixed raw materials into the ball milling tank of the ball mill, and then add stainless steel or tungsten carbide grinding balls with a diameter of 3mm. protection or vacuum treatment;

[0036] (3) After the ball mill jar is put into the furnace of the ball mill, the mixed raw materials are ball milled by setting the speed of the motor of the ball mill to 450-500rpm;

[0037] (4) After the furnace with the ball milling tank is heated to 850°C at a heating rate of 4°C / min, the furnace is kept warm for 80h, and during the heating and heat preservation process of the furnace, the ball mill continues to grind the mixed raw materials;

[0038] (5) Close the ball mill, and cool the furnace to room temperature, ...

Embodiment 2

[0040] A method for preparing superfine tungsten carbide powder with tungsten powder and nickel powder as raw materials, comprising:

[0041] (1) 90g tungsten powder, 9g carbon black and 7g tungsten powder are mixed to prepare mixed raw materials;

[0042] (2) Put the mixed raw materials into the ball milling tank of the ball mill, and then add stainless steel or tungsten carbide grinding balls with a diameter of 3mm. protection or vacuum treatment;

[0043] (3) After the ball mill jar is put into the furnace of the ball mill, the mixed raw materials are ball milled by setting the speed of the motor of the ball mill to 450-500rpm;

[0044] (4) After the furnace with the ball mill tank is heated to 750°C at a heating rate of 6°C / min, the furnace is kept warm for 65h, and during the heating and heat preservation process of the furnace, the ball mill continues to grind the mixed raw materials;

[0045](5) Close the ball mill, and cool the furnace to room temperature, take out t...

Embodiment 3

[0047] A method for preparing superfine tungsten carbide powder with tungsten powder and nickel powder as raw materials, comprising:

[0048] (1) 90g tungsten powder, 8.4g carbon black and 8g tungsten powder are mixed to prepare mixed raw materials;

[0049] (2) Put the mixed raw materials into the ball milling tank of the ball mill, and then add stainless steel or tungsten carbide grinding balls with a diameter of 3mm. protection or vacuum treatment;

[0050] (3) After the ball mill jar is put into the furnace of the ball mill, the mixed raw materials are ball milled by setting the speed of the motor of the ball mill to 450-500rpm;

[0051] (4) After the furnace with the ball milling tank is heated to 800°C at a heating rate of 5°C / min, the furnace is kept warm for 50h, and during the heating and heat preservation process of the furnace, the ball mill continues to grind the mixed raw materials;

[0052] (5) Close the ball mill, and cool the furnace to room temperature, take...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com