Full-automatic glass bottle decoration firing and film removal machine

A technology of glass bottles and film stripping machines, which is applied in the field of film stripping machines, can solve the problems of long time consumption, low efficiency, and increased labor cost, etc., and achieve the effects of high degree of automation, good film breaking effect, and good film blowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

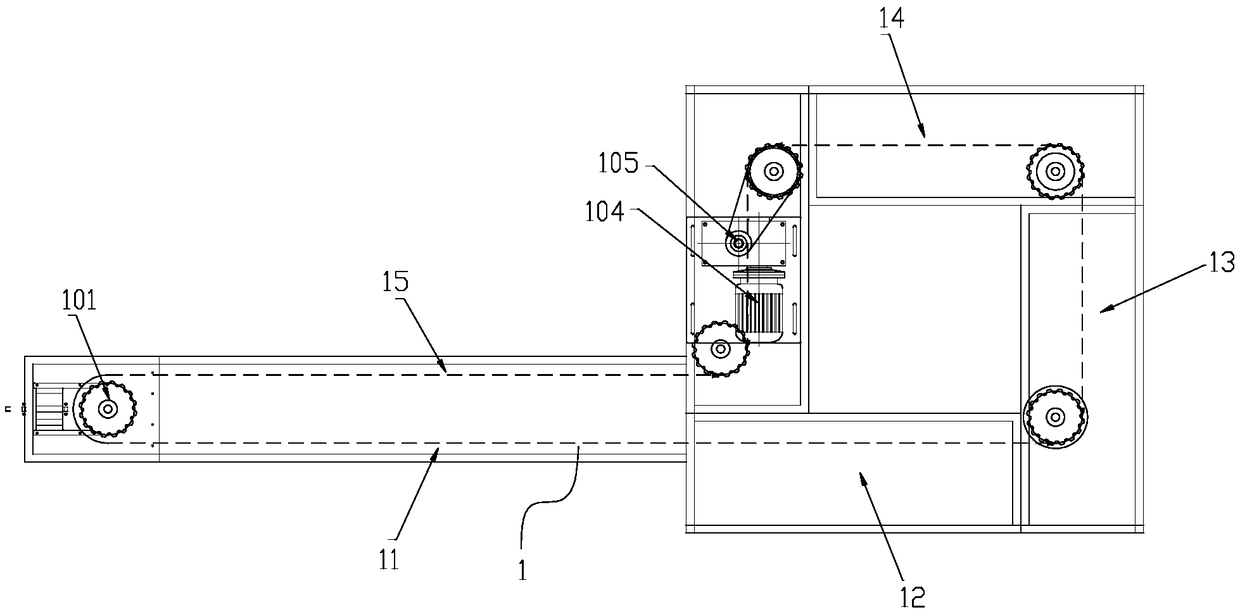

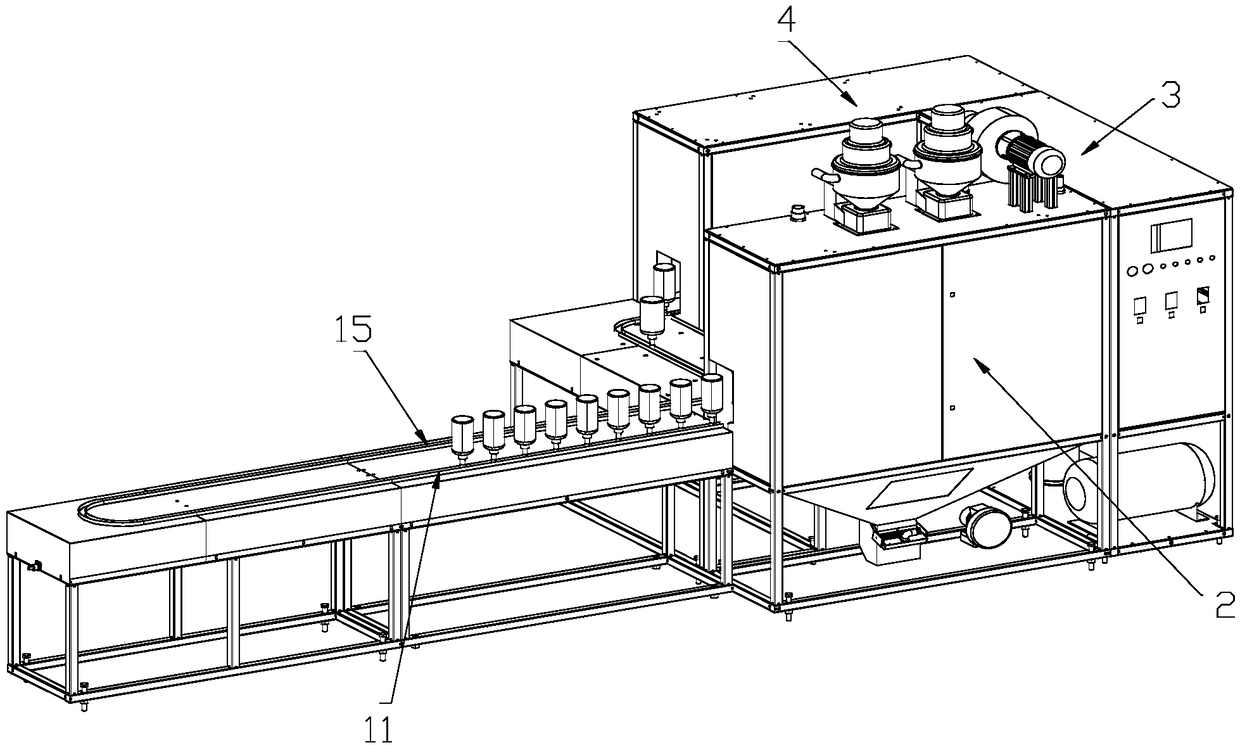

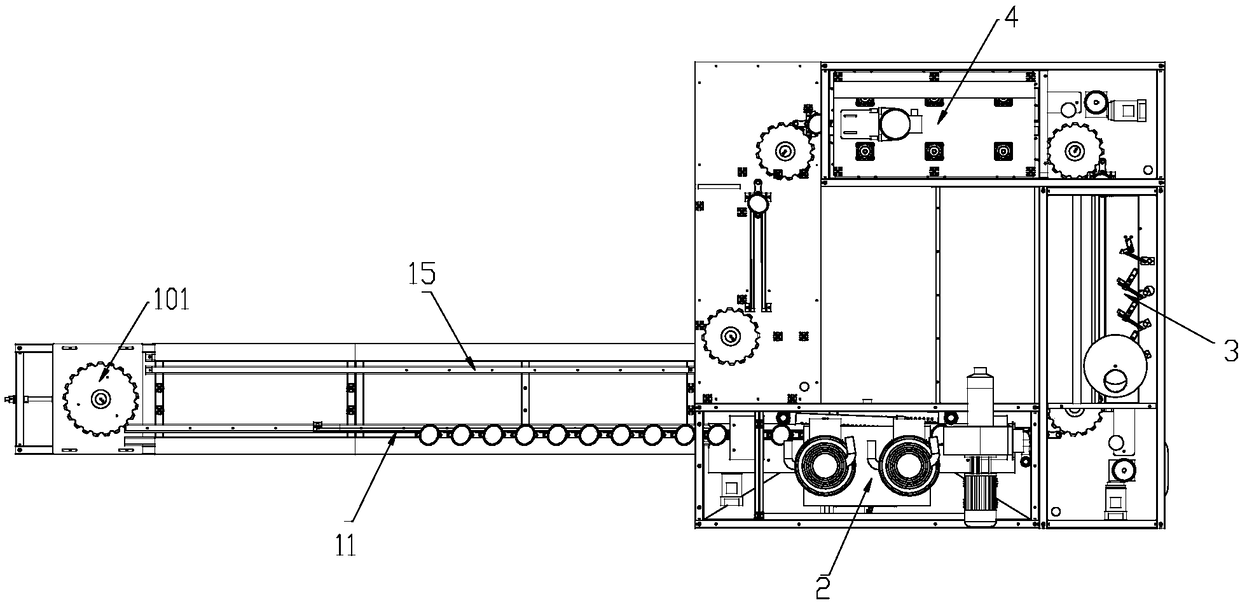

[0048] Such as Figure 1 to Figure 21 As shown, a kind of fully automatic glass bottle baking flower stripping machine provided by the embodiment of the present invention includes a stripping line 1 and a film breaking mechanism 2, a film blowing mechanism 3 and a cleaning mechanism 4 set up on the stripping line 1 in sequence The stripping line 1 includes a feeding area 11, a film breaking area 12, a film blowing area 13, a cleaning area 14 and a feeding area 15 distributed in sequence, the film breaking mechanism 2 is set up in the film breaking area 12, and the film blowing mechanism 3 is set up in the film breaking area 12. The film blowing area 13, the cleaning mechanism 4 is erected in the cleaning area 14; the film breaking mechanism 2 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com