Plastic film with high stretching resistance and preparation process thereof

A plastic film and high-resistance technology, applied in the field of plastic film, can solve the problems of easy tearing and low strength of plastic film, and achieve the effect of improving heat insulation ability, thin wall thickness and heat insulation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

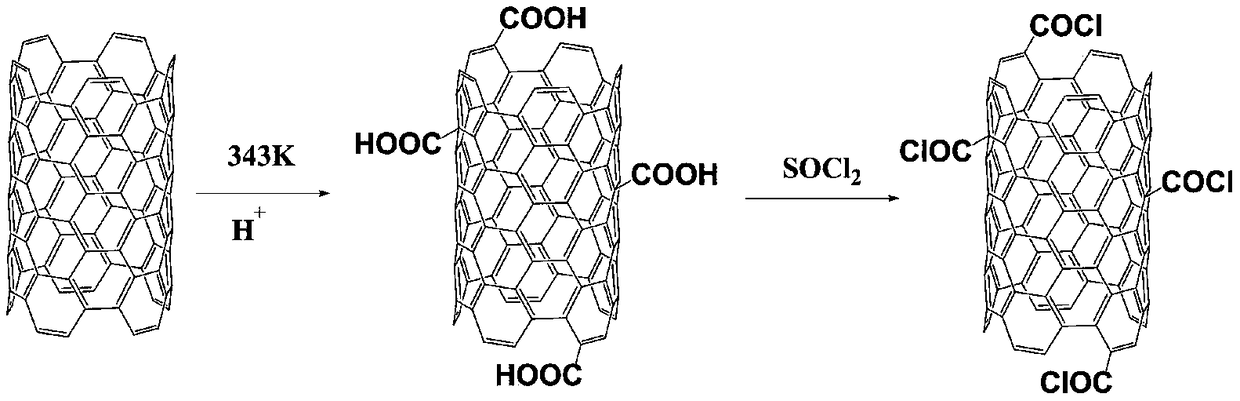

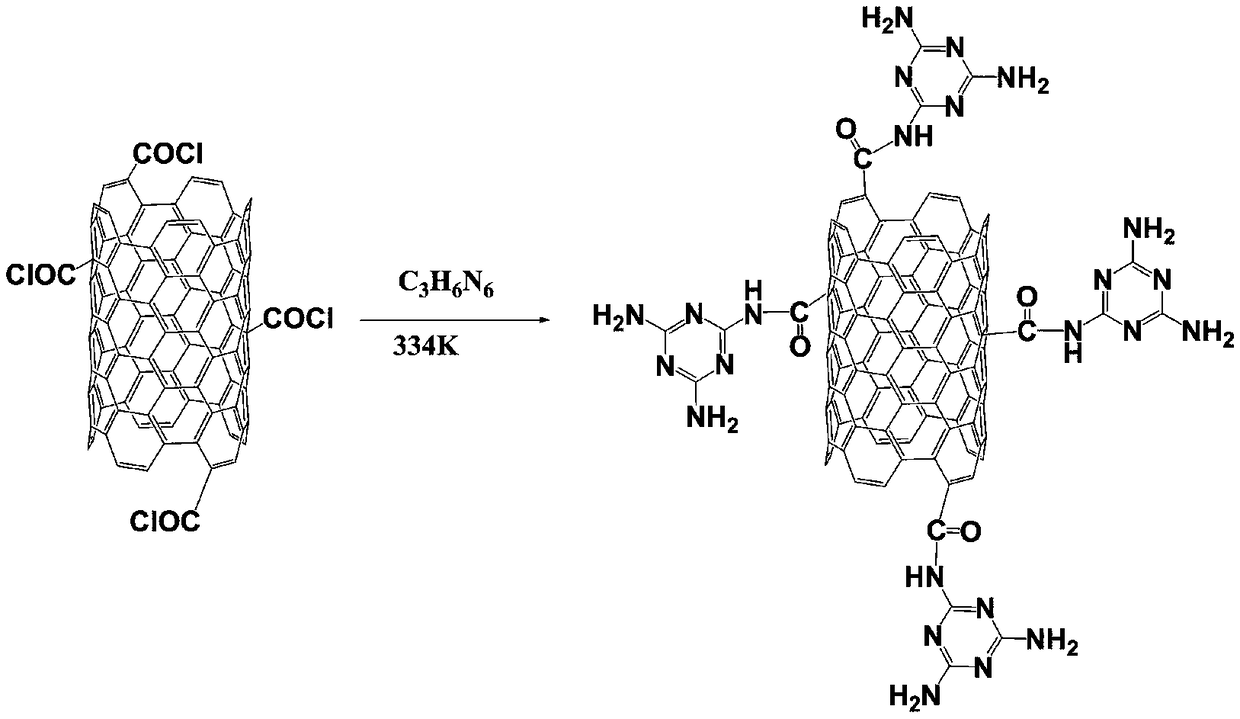

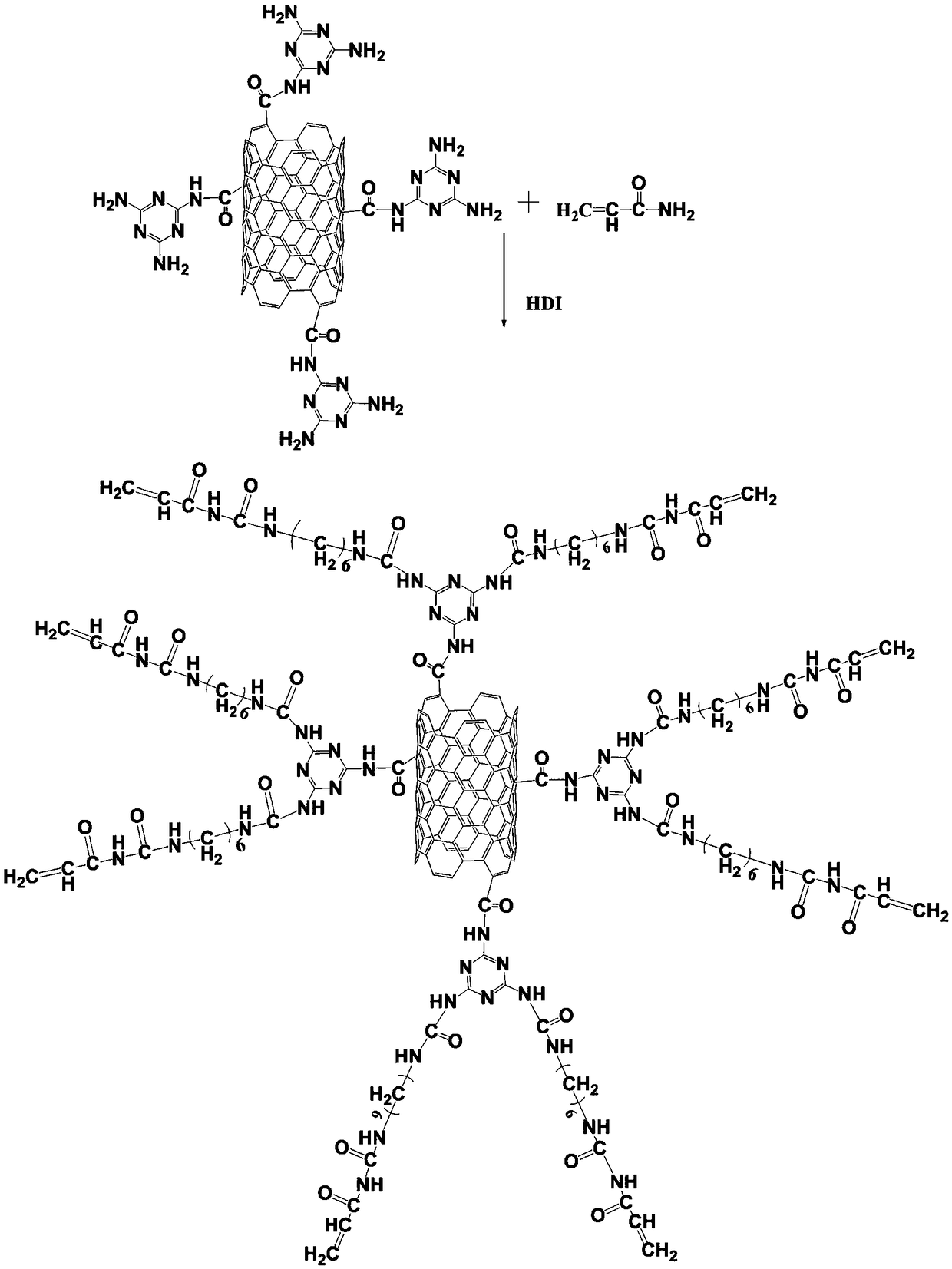

[0038] The specific preparation process of grafted carbon nanotubes is as follows:

[0039] Step 1: Weigh 1 kg of carbon nanotubes and add them to a mixed solution of 1 L of concentrated nitric acid and 3 L of concentrated sulfuric acid. After ultrasonic dispersion for 30 minutes, pour the solution into a reaction flask, heat to 70 ° C for 2 hours, then filter, wash, and dry to obtain Oxidized carbon nanotubes;

[0040] Step 2: Add 1 kg of oxidized carbon nanotubes and 12 L of thionyl chloride prepared in step 1 into a reaction vessel, raise the temperature to 60° C. for 3 hours, and then filter and wash to obtain carbonyl chloride carbon nanotubes;

[0041] Step 3: Add 1kg of carbonyl chloride carbon nanotubes prepared in step 2 into 7L of water, add 750g of α-cyclodextrin to it, and add 800g of sodium lauryl sulfate to it at the same time, then raise the temperature to 80°C and stir for 40-50min, Filtration while hot to obtain hole-filled carbon nanotubes;

[0042] Step 4:...

Embodiment 2

[0046] The specific preparation process of grafted carbon nanotubes is as follows:

[0047] Step 1: Weigh 1 kg of carbon nanotubes and add them to a mixed solution of 1 L of concentrated nitric acid and 3 L of concentrated sulfuric acid. After ultrasonic dispersion for 30 minutes, pour the solution into a reaction flask, heat to 70 ° C for 2 hours, then filter, wash, and dry to obtain Oxidized carbon nanotubes;

[0048] Step 2: Add 1 kg of oxidized carbon nanotubes and 13 L of thionyl chloride prepared in step 1 into a reaction vessel, raise the temperature to 60° C. for 3 hours, and then filter and wash to obtain carbonyl chloride carbon nanotubes;

[0049] Step 3: Add 1kg of carbonyl chloride carbon nanotubes prepared in step 2 into 7L of water, add 790g of α-cyclodextrin into it, and add 900g of sodium lauryl sulfate into it at the same time, then raise the temperature to 80°C and stir for 40-50min, Filtration while hot to obtain hole-filled carbon nanotubes;

[0050] Ste...

Embodiment 3

[0054] The specific preparation process of grafted carbon nanotubes is as follows:

[0055] Step 1: Weigh 1 kg of carbon nanotubes and add them to a mixed solution of 1 L of concentrated nitric acid and 3 L of concentrated sulfuric acid. After ultrasonic dispersion for 30 minutes, pour the solution into a reaction flask, heat to 70 ° C for 2 hours, then filter, wash, and dry to obtain Oxidized carbon nanotubes;

[0056] Step 2: Add 1 kg of oxidized carbon nanotubes and 12 L of thionyl chloride prepared in step 1 into a reaction vessel, raise the temperature to 60° C. for 3 hours, and then filter and wash to obtain carbonyl chloride carbon nanotubes;

[0057] Step 3: Add 1kg of carbonyl chloride carbon nanotubes prepared in step 2 into 7L of water, add 750g of α-cyclodextrin to it, and add 800g of sodium lauryl sulfate to it at the same time, then raise the temperature to 80°C and stir for 40-50min, Filtration while hot to obtain hole-filled carbon nanotubes;

[0058] Step 4:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com