Preparation method of platinum nano cage and application to catalyst

A gold nanocage and gold nanoparticle technology, which is applied in the field of synthesis of nanomaterials, can solve the problems of reduced catalytic activity and poor stability of platinum-based nanomaterials, and achieve the effects of easy implementation, easy scale-up, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

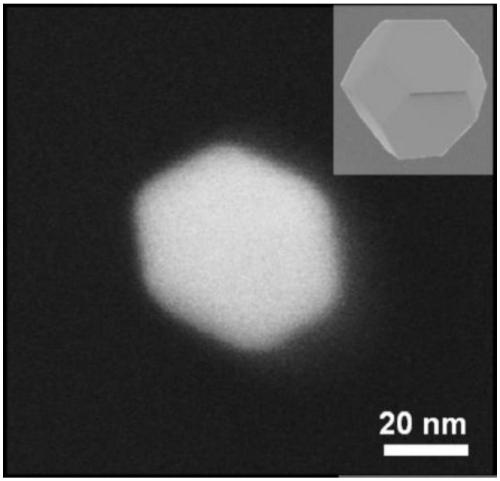

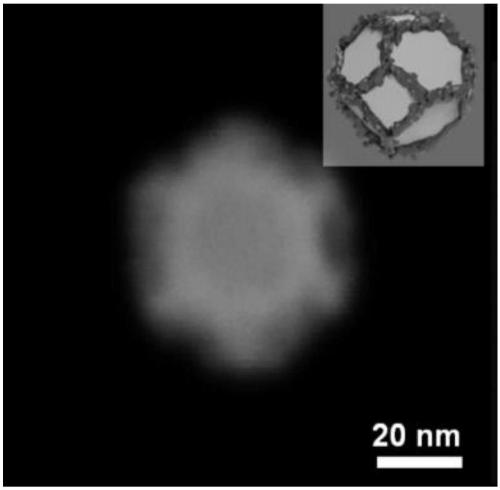

[0044] A kind of preparation method of platinum-gold nanocage, described preparation method comprises the steps:

[0045] a. Preparation of gold nanoseed solution: Add 7.5mL 0.5mol / L cetyltrimethylammonium bromide and 87.5μL 0.02mol / L tetrahydrate chloroauric acid tetrahydrate solution in a 50mL round bottom flask, under vigorous stirring Add 0.6 mL of 0.01 mol / L sodium borohydride solution in an ice bath, and then continue stirring at 25°C for 3 hours to obtain a 3-5 nm gold nanometer seed solution. The reaction involved in step a is 8HAuCl 4 ·3H 2 O+3NaBH 4 =8Au+3NaB(OH) 4 +12H 2 O+32HCl

[0046] b. Preparation of cut-angle octahedral gold nanoparticles solution:

[0047] b1. Dilute the gold nano-seed solution obtained in step a 100 times with water to obtain a diluted gold nano-seed solution, add 12mL 0.016mol / L hexadecyltrimethylammonium bromide solution in a round bottom flask, 25 μL 0.02mol / L chloroauric acid tetrahydrate solution, 25 μL 0.0388mol / L sodium citrat...

Embodiment 2

[0062] A thin-film catalyst, described thin-film catalyst is prepared from the cut-angle octahedral platinum-gold nanocage solution that utilizes embodiment 1 to obtain, and its preparation process is as follows:

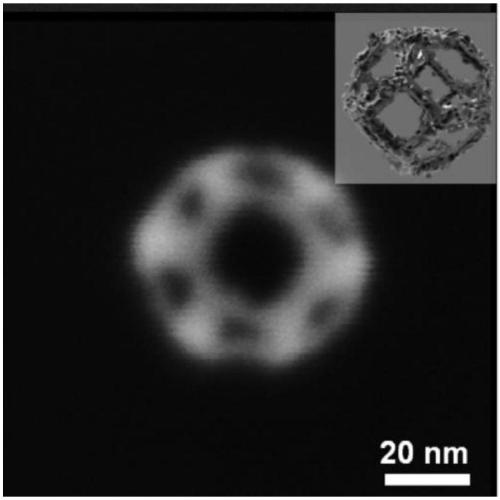

[0063] Take 2 μL of cut-angle octahedral platinum-gold nanocage solution and drop it on the surface of the conductive material of the glassy carbon plate, volatilize in an oven at 70 degrees Celsius for 10 minutes, repeat this step to obtain a three-dimensional ordered cut-angle octahedral platinum-gold nanocage film with a thickness of 7 μm Catalysts such as Figure 4 As shown, what is shown is the scanning electron microscope image of the obtained angular-cut octahedral platinum-gold nanocage thin film catalyst, and the lower right corner is a structural schematic diagram. porous structure.

Embodiment 3

[0065] The angle-cut octahedral platinum-gold nanocage film catalyst obtained in Example 2 is pretreated by cyclic voltammetry scanning, the voltage range is 0.6 to 1.0 volts, and the electrolyte is 0.1mol / L sulfuric acid, until the cyclic voltammetry can be obtained until repeated.

[0066] Before testing the methanol oxidation performance of the catalyst, the electrolyte (0.1 mol / L sulfuric acid and 1 mol / L methanol) was blown with nitrogen to remove dissolved oxygen for 10 minutes.

[0067] The cleaved octahedral platinum-gold nanocage thin film catalyst, the platinum-coated cleaved octahedral gold nanoparticle catalyst and the 10% Pt / C E-TEK catalyst with the same specific surface area were applied to the catalytic oxidation of methanol. Cyclic voltammetry was compared as Figure 5 Shown are the comparison diagrams of cyclic voltammetry polarization curves of the three catalysts in 0.1mol / L sulfuric acid and 1mol / L methanol solutions, s1, s2, s3 respectively represent the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com