Carbon nanotube/copper-zinc alloy composite material as well as preparation method and application thereof

A carbon nanotube and composite material technology, which is applied in the field of carbon nanotube/copper-zinc alloy composite material and its preparation, can solve the problem that the level of copper refining cannot meet the process requirements, the purity of the copper-zinc alloy layer is not high, and the stability of the catalyst is affected and other problems, to achieve the effect of reducing the occurrence of reunion, reducing the loss, and inhibiting the growth of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of preparation method of carbon nanotube / copper-zinc alloy composite material of the present invention comprises the following steps:

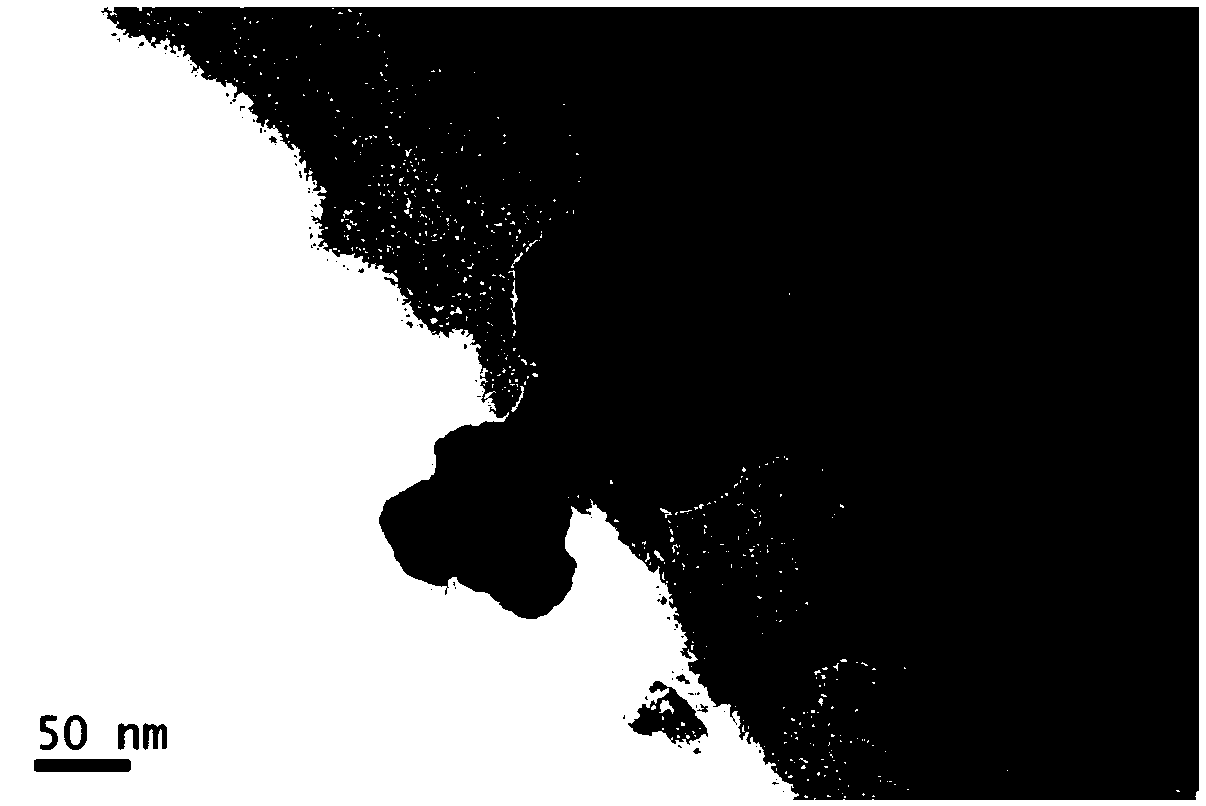

[0038](1) Acid treatment: using multi-walled carbon nanotubes as the matrix, the CNTs are about 500nm long and 20-25nm wide, put the CNTs into a mixture of concentrated sulfuric acid and concentrated nitric acid (volume ratio 3:1) and heat at 110°C for 2h , washed with a large amount of deionized water to obtain acid-treated CNTs, the concentration of CNTs is 5g / l, and the transmission electron microscope picture is as follows figure 1 shown;

[0039] (2) Sensitization treatment: take by weighing 2.5g tin protochloride and dissolve in 2.5ml concentrated hydrochloric acid (mass concentration is 36%), add water and dilute to 100ml, obtain sensitization liquid, get 8ml step (1) after the acid treatment of gained CNTs were added to the sensitization solution for ultrasonic treatment for 10 minutes, and cleaned with a large amount of...

Embodiment 2

[0052] A kind of preparation method of carbon nanotube / copper-zinc alloy composite material of the present invention comprises the following steps:

[0053] (1) Acid treatment: using multi-walled carbon nanotubes as the matrix, the CNTs are about 500nm long and 20-25nm wide, put the CNTs into a mixture of concentrated sulfuric acid and concentrated nitric acid (volume ratio 2:1) and heat at 110°C for 2h , washed with a large amount of deionized water to obtain acid-treated CNTs, the concentration of CNTs is 5g / l;

[0054] (2) Sensitization treatment: take by weighing 2.5g tin protochloride and dissolve in 2.5ml concentrated hydrochloric acid (mass concentration is 36%), add water and dilute to 100ml, obtain sensitization liquid, get 8ml step (1) after the acid treatment of gained CNTs were added to the sensitization solution for ultrasonic treatment for 10 minutes, and cleaned with a large amount of deionized water to obtain sensitized CNTs;

[0055] (3) Activation treatment:...

Embodiment 3

[0067] A kind of preparation method of carbon nanotube / copper-zinc alloy composite material of the present invention comprises the following steps:

[0068] (1) Acid treatment: using multi-walled carbon nanotubes as the matrix, the CNTs are about 500nm long and 20-25nm wide, put the CNTs into a mixture of concentrated sulfuric acid and concentrated nitric acid (volume ratio 2:1) and heat at 110°C for 2h , washed with a large amount of deionized water to obtain acid-treated CNTs, the concentration of CNTs is 5g / l;

[0069] (2) Sensitization treatment: take by weighing 2.5g tin protochloride and dissolve in 2.5ml concentrated hydrochloric acid (mass concentration is 36%), add water and dilute to 100ml, obtain sensitization liquid, get 8ml step (1) after the acid treatment of gained CNTs were added to the sensitization solution for ultrasonic treatment for 10 minutes, and cleaned with a large amount of deionized water to obtain sensitized CNTs;

[0070] (3) Activation treatment:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com