Apparatus and method for evaluating the life of heat exchange tubes of biomass fuel boilers

A technology of biomass fuel and heat exchange tubes, which is applied in the direction of measuring devices, measuring heat, and thermometers, etc., can solve problems such as boiler operation accidents, tube bursts, and inability to monitor the corrosion of heat exchange tubes to ensure safety and reliability running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

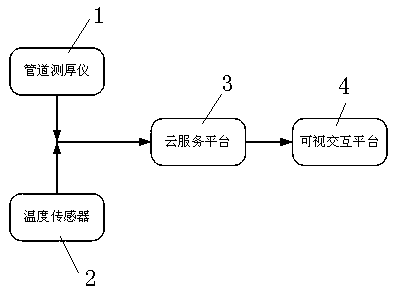

[0028] Example figure 1 As shown, the evaluation device for the life of the biomass fuel boiler heat exchange tube of the present invention includes a pipeline thickness gauge 1, a temperature sensor 2, a cloud service platform 3 and a visual interaction platform 4, and the pipeline thickness gauge 1 and the temperature sensor 2 are respectively Detect the wall thickness of the heat exchange tube and the flue gas temperature at the measured wall thickness, and transmit the detected data to the cloud service platform 3 via a wired network or a wireless network, and the cloud service platform 3 has a built-in boiler flue gas temperature during operation For distributing data, the cloud service platform 3 communicates with the visual interaction platform 4, and the visual interaction platform 4 provides curve, three-dimensional modeling, printing, and life-span early warning services according to requirements.

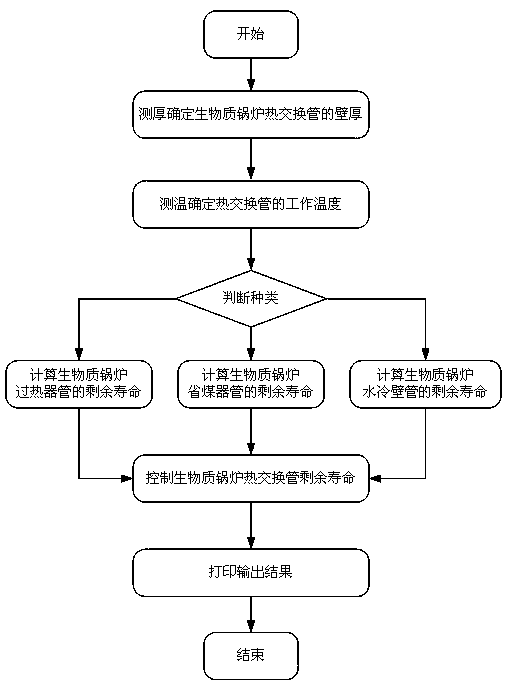

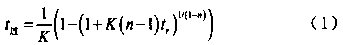

[0029] A method for evaluating the life of a biomass fuel boiler hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com