High-strength easy-to-clean elastic non-woven fabric

A non-woven, easy-to-clean technology, applied in the direction of non-woven fabrics, textiles, and papermaking, can solve the problems of limited selection range and characteristics, high fiber density, and high cost, and achieve enhanced mechanical properties, comfortable hand feeling, and stable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

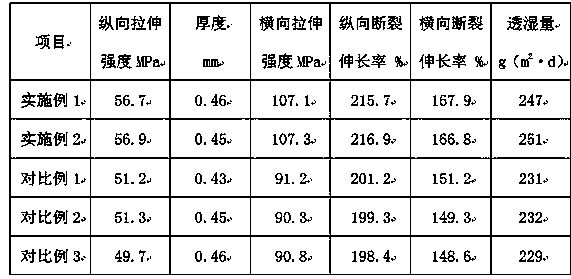

Examples

Embodiment 1

[0020] A high-strength and easy-to-clean elastic non-woven fabric, the non-woven material is made of the following raw materials in parts by weight: 560 parts of POE, 70 parts of polypropylene, 20 parts of polyvinylpyrrolidone, 3 parts of carbon nanotubes, polyethylene glycol 10 parts, 1 part of carbon fiber, 10 parts of modified polyethylacrylate, 5 parts of ion-modified clay, 1 part of surface modifier, and 10 parts of thermoplastic polyurethane.

[0021] A high-strength and easy-to-clean elastic non-woven fabric, the preparation method of which comprises: the first step, weighing each raw material, putting POE and polypropylene into a high-speed mixer and stirring for 5 to 10 minutes, then adding polyvinylpyrrolidone, 30 parts of acetone and surface modifier, stirred for 5-10 minutes, adsorbed and dried to obtain the mixture; in the second step, the mixture was added to n-hexane, and the temperature was raised to 60-70°C under nitrogen protection, and the reaction was carrie...

Embodiment 2

[0028]A high-strength and easy-to-clean elastic non-woven fabric, the non-woven fabric material is made of the following raw materials in parts by weight: 55 parts of POE, 70 parts of polypropylene, 20 parts of polyvinylpyrrolidone, 3 parts of carbon nanotubes, polyethylene glycol 20 parts, 5 parts of carbon fiber, 20 parts of modified polyethylacrylate, 5 parts of ion-modified clay, 1 part of surface modifier, and 10 parts of thermoplastic polyurethane.

[0029] A high-strength and easy-to-clean elastic non-woven fabric, the preparation method of which comprises: the first step, weighing each raw material, putting POE and polypropylene into a high-speed mixer and stirring for 5 to 10 minutes, then adding polyvinylpyrrolidone, 30 parts of acetone and surface modifier, stirred for 5-10 minutes, adsorbed and dried to obtain the mixture; in the second step, the mixture was added to n-hexane, and the temperature was raised to 60-70°C under nitrogen protection, and the reaction was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com