Method for preparing copper-graphene compound plating layer, chemical plating solution and plating solution preparation method

A technology of graphene composite and chemical plating solution, which is applied in the field of chemical plating, can solve the problems of easy agglomeration of Gr or GO, direct decomposition of the plating solution, and reduced stability of the plating solution, and achieves the advantages of easy operation, low cost and improved performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

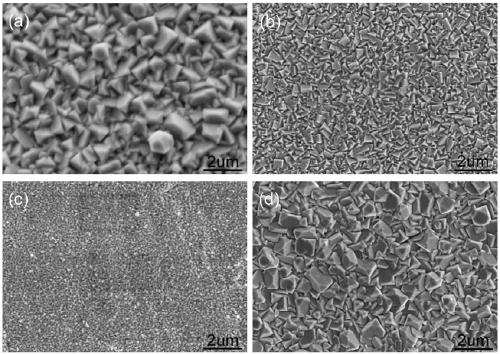

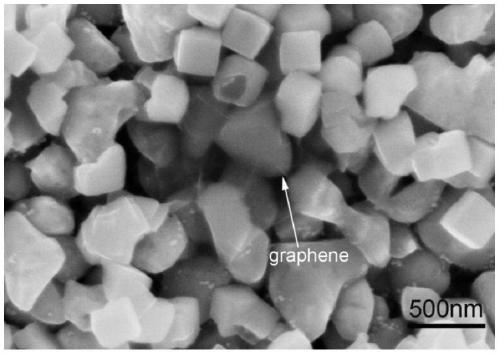

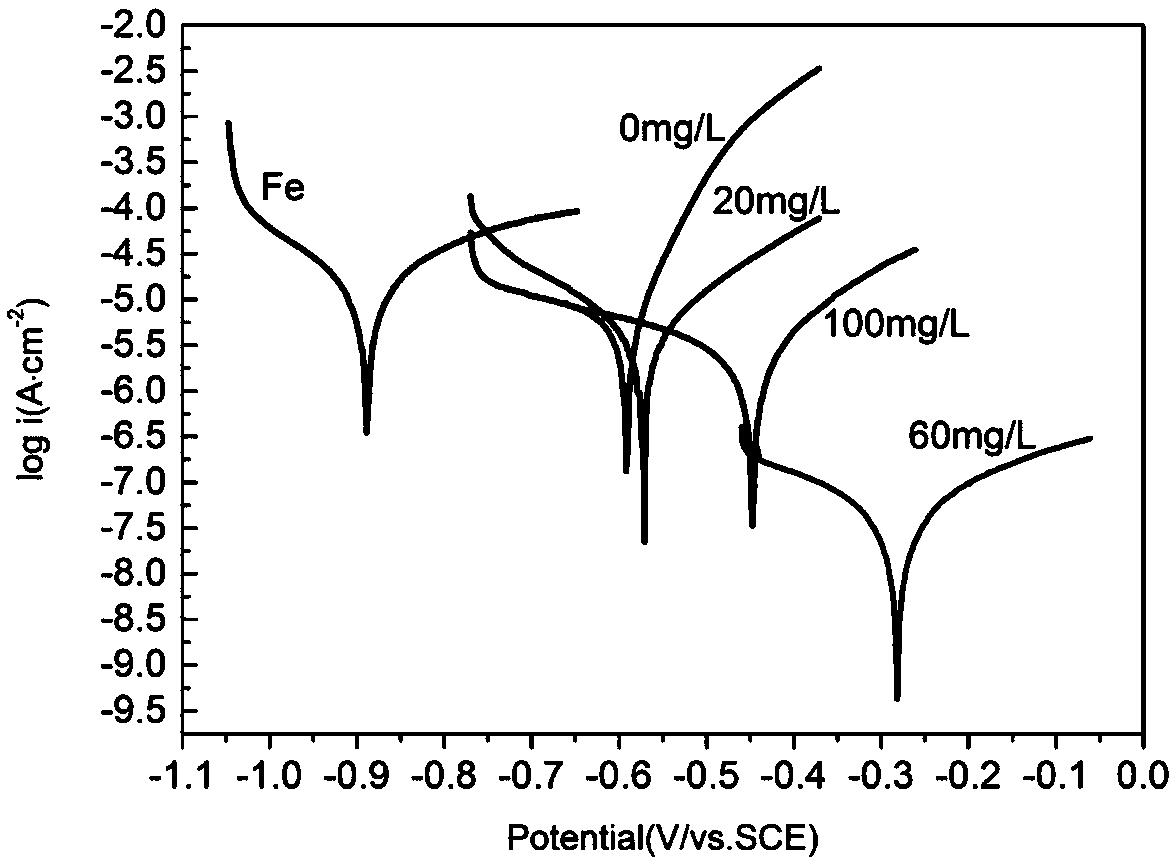

Method used

Image

Examples

Embodiment 1

[0044] A kind of electroless plating method prepares the plating solution of Cu-Gr composite plating layer, calculates by every liter of composite plating solution, its component and content are as follows:

[0045]

[0046]

[0047] Above-mentioned electroless plating method prepares the plating solution of Cu-Gr composite coating by the method preparation of following steps:

[0048] Sodium citrate dihydrate, copper sulfate pentahydrate, sodium hypophosphite monohydrate, boric acid, and nickel sulfate heptahydrate were sequentially added to distilled water to dissolve, and graphene oxide GO was added under stirring conditions, and then oxidized with 5% hydroxide The sodium solution adjusts the pH value to 9-9.5, and finally the plating solution is ultrasonicated for 1-3 hours to obtain a well-dispersed Cu-GO composite chemical plating solution.

Embodiment 2

[0060] A kind of electroless plating method prepares the plating solution of Cu-Gr composite coating, calculates by every liter of composite plating solution, and its component and content are as follows:

[0061]

[0062] The above-mentioned a kind of electroless plating method prepares the plating solution preparation method of Cu-Gr composite coating with embodiment 1.

Embodiment 3

[0075] A kind of electroless plating method prepares the plating solution of Cu-Gr composite coating, calculates by every liter of composite plating solution, and its component and content are as follows:

[0076]

[0077] The above-mentioned a kind of electroless plating method prepares the plating solution preparation method of Cu-Gr composite coating with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion potential | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com