A modified sepiolite-coated titanium nano heavy-duty anti-corrosion coating and its preparation method

A technology of sepiolite and titanium nanometers, which is applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of expensive titanium and poor dispersion of titanium nanometers, and reduce the risk of corrosion. Increased repulsion and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

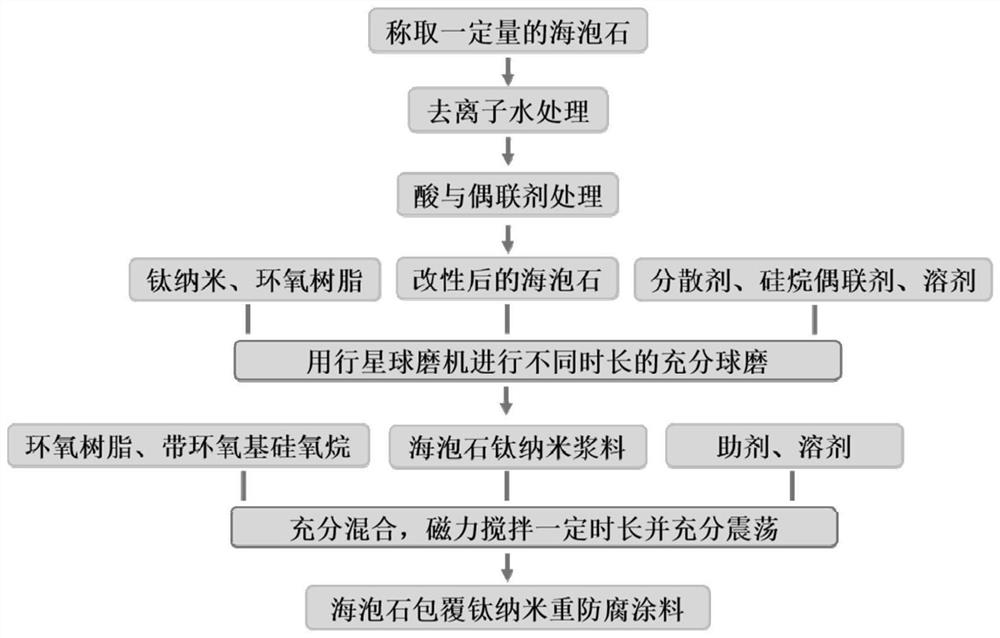

[0037] The specific operation steps are as follows:

[0038] (1). First, 20g of sepiolite with a purity of 70% is screened with a 200-mesh screen, and then the screened sepiolite is soaked in deionized water, fully magnetically stirred at 1200r / min for 24h, and then left to settle 48h, then dried at 95°C for 24h, and fully ground for 40min to obtain sepiolite powder treated with deionized water; Add the coupling agent γ-propyltrimethoxysilane into 2mol / L dilute hydrochloric acid solution, fully stir in the oil bath at 95°C at 1400r / min for 40min, repeatedly suction filter and dehydrate, and finally use 115 ℃, vacuum-dried, and fully ground for 30 minutes to obtain silane coupling agent-modified sepiolite;

[0039] (2). The modified sepiolite with a quality of 4g is mixed with titanium powder with a quality of 64g, and after fully grinding, add epoxy resin E44, dispersion medium dimethylpyrrolidone, silane coupling agent AL-303, solvent, Their masses are 36g, 7g, 4g, and 35g ...

Embodiment 2

[0046] The specific operation steps are as follows:

[0047](1) First, 17g of sepiolite with a purity of 70% is screened with a 200-mesh screen, and then the screened sepiolite is soaked in deionized water, fully magnetically stirred at 1000r / min for 36h, and then left to settle for 36h , then dried at 90°C for 36 hours, fully ground for 30 minutes to obtain sepiolite powder treated with ionized water; The joint agent γ-propyltrimethoxysilane is added to 2mol / L dilute hydrochloric acid solution, fully stirred in an oil bath at 90°C at 1500r / min for 50min, repeatedly suction-filtered and dehydrated, and finally heated at 105°C Vacuum drying, fully grinding for 40min to obtain the sepiolite modified by silane coupling agent;

[0048] (2) The modified sepiolite with a quality of 8g is mixed with titanium powder with a quality of 65g, and after fully grinding, add epoxy resin E44, dispersion medium dimethylpyrrolidone, silane coupling agent AL-303, solvent, they The mass is 42g,...

Embodiment 3

[0056] The specific operation steps are as follows:

[0057] (1). First, screen 15g of sepiolite with a purity of 70% with a 200-mesh screen, then soak the screened sepiolite in deionized water, and stir magnetically at 1100r / min for 22 hours, then let it settle 40h, then dried at 100°C for 24h, and fully ground for 30min to obtain sepiolite powder treated with deionized water; Add the coupling agent γ-propyltrimethoxysilane into 2mol / L dilute hydrochloric acid solution, fully stir in the oil bath at 1300r / min at 95°C for 30min, repeat suction filtration and dehydration, and finally use 115 °C, vacuum-dried and fully ground for 50 minutes to obtain silane coupling agent-modified sepiolite.

[0058] (2). The modified sepiolite with a quality of 20g is mixed with titanium powder with a quality of 80g, and after fully grinding, add epoxy resin E44, dispersion medium dimethylpyrrolidone, silane coupling agent AL-303, solvent, Their masses are 32g, 6g, 4g, and 15g in turn, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com