Short carbon fiber reinforced phenol formaldehyde resin-based composite material and preparation method thereof

A technology of chopped carbon fiber and phenolic resin, which is applied in the field of chopped carbon fiber reinforced phenolic resin-based composite materials and its preparation, can solve the problems of large batch differences in product performance and difficulty in taking into account the uniformity of chopped carbon fiber distribution, and achieve simple operation , Each process is accurate and controllable, and the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

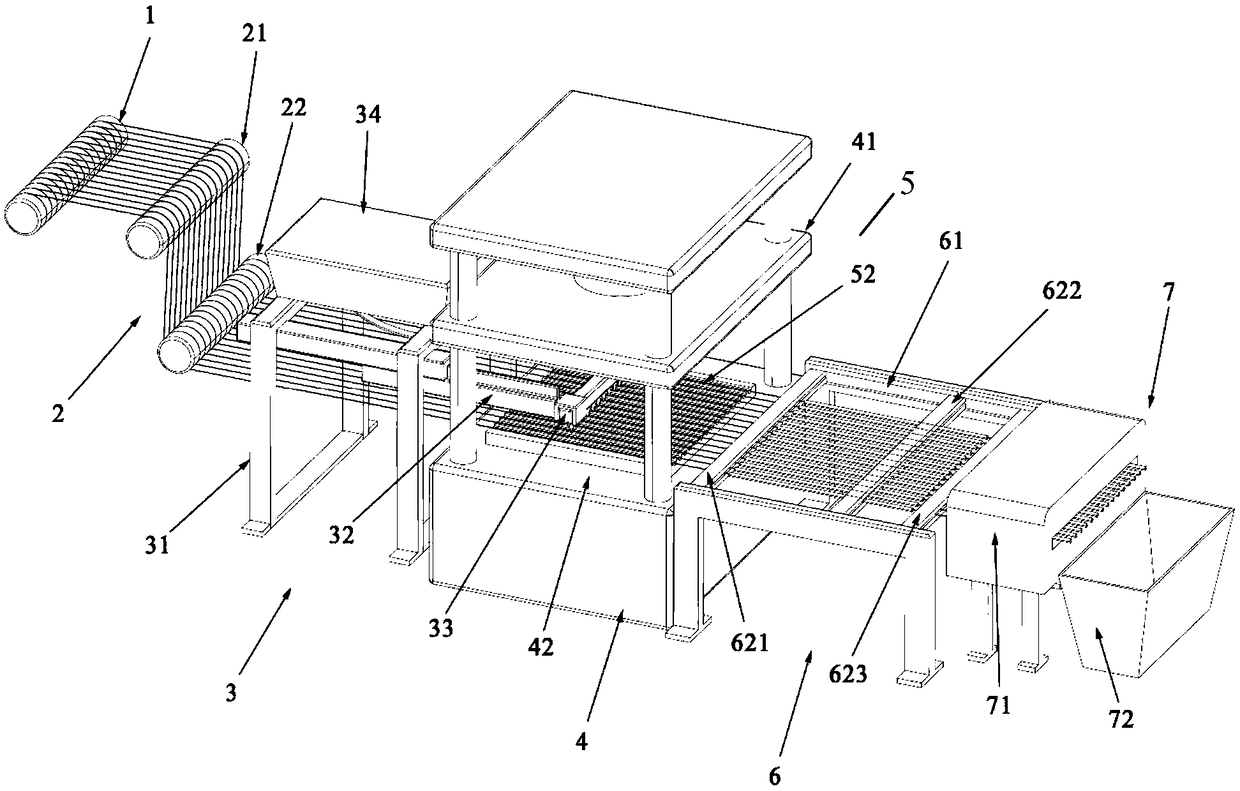

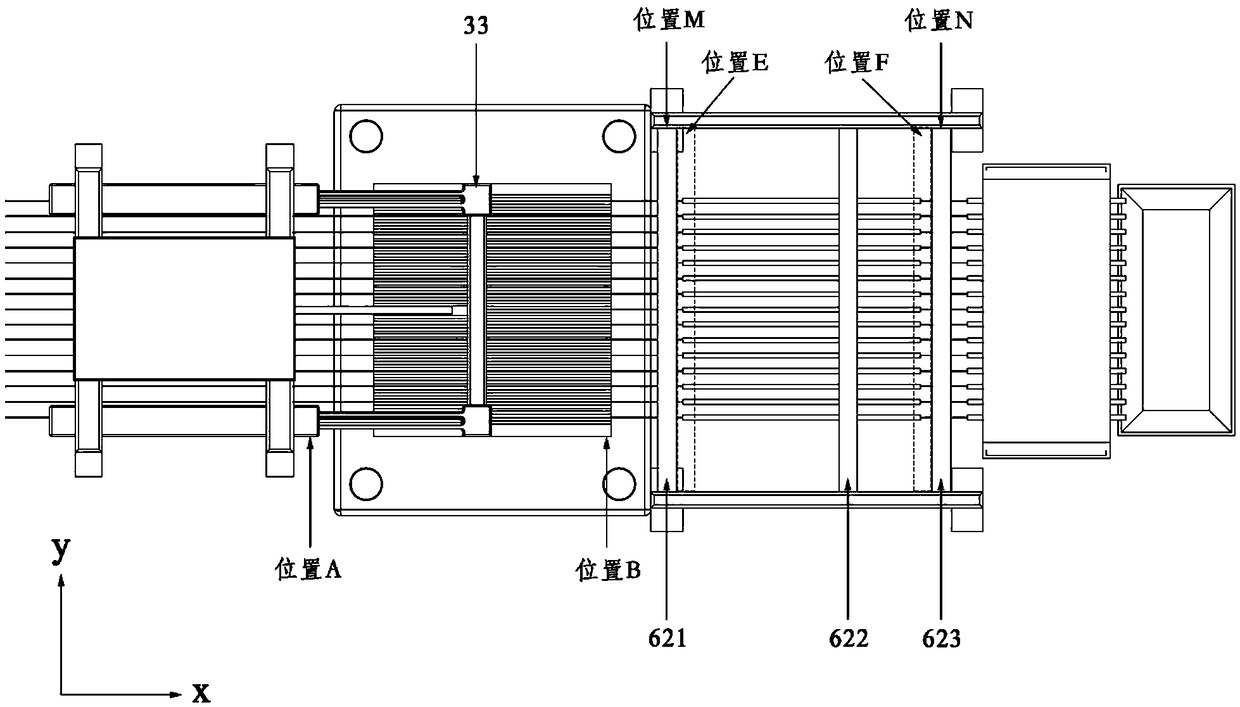

Method used

Image

Examples

Embodiment 1

[0059] Step 1: Take 3k continuous carbon fiber bundles and heat-treat them in an argon atmosphere furnace at 900°C to remove surface metal ions and impurities, then clean them with acetone and deionized water as cleaning agents until the surface is free of glue, and finally wash the The continuous carbon fiber bundle is placed in an oven for drying, and wound to obtain a pretreated continuous carbon fiber bundle;

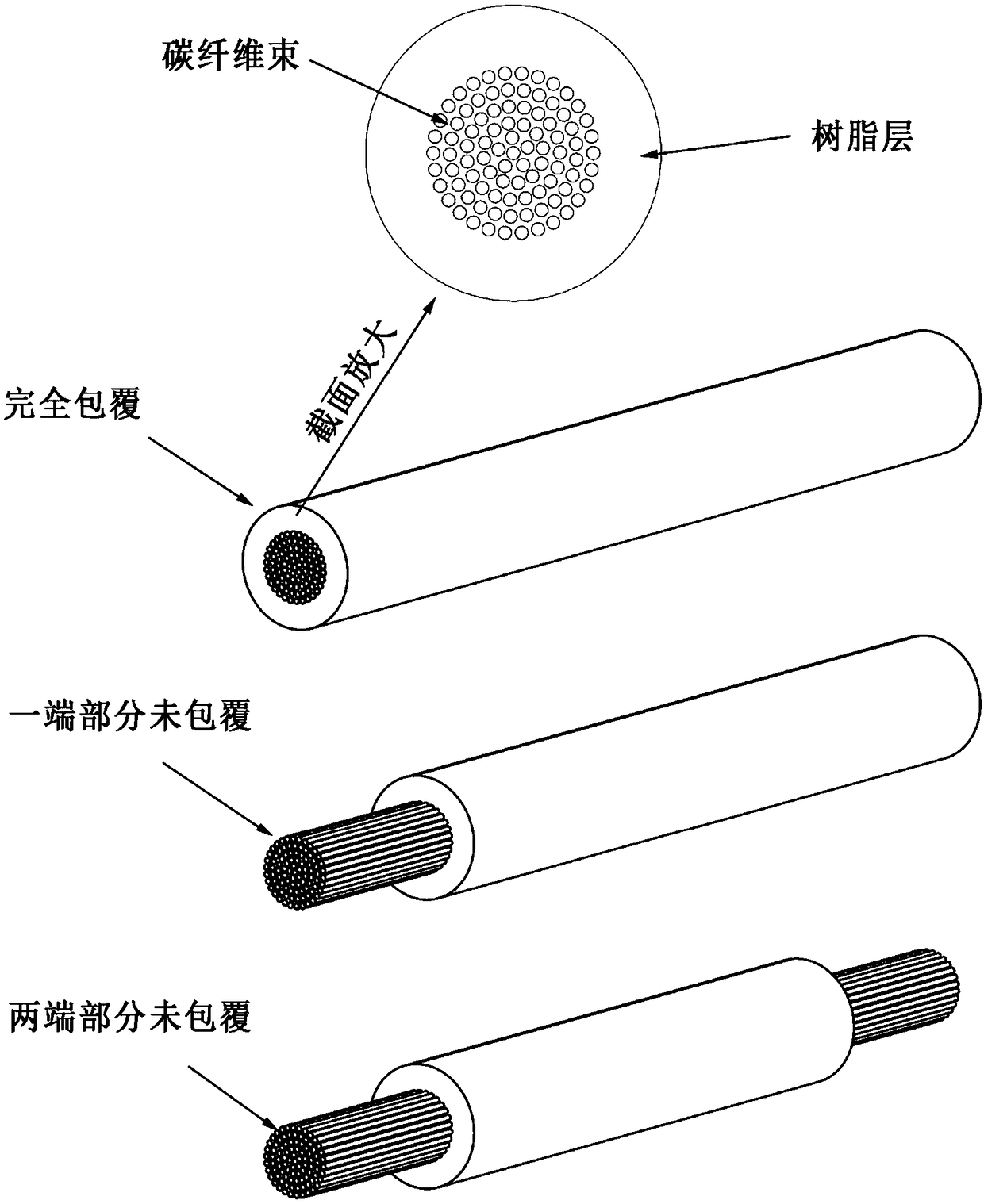

[0060] Step 2: Pass the pretreated continuous carbon fiber bundle obtained in step 1 through the equipment for preparing chopped carbon fiber bundles with a surface coated with a phenolic resin layer to prepare chopped carbon fiber bundles with a surface coated with a phenolic resin layer, and the phenolic resin layer completely covers the short carbon fiber bundles. The carbon fiber is cut and in a semi-cured state, the thickness is 0.5mm, and the length of the chopped carbon fiber bundle covered with the resin layer is 5mm;

[0061] Step 3: Proportionally weigh th...

Embodiment 2

[0072] Step 1: Take 24k continuous carbon fiber bundles and heat-treat them in an argon atmosphere furnace at 1600°C to remove surface metal ions and impurities, then clean them with acetone and deionized water as cleaning agents until the surface is free of glue, and finally clean the The continuous carbon fiber bundle is placed in an oven and dried to obtain a pretreated continuous carbon fiber bundle;

[0073]Step 2: Pass the pretreated continuous carbon fiber bundles through the equipment for preparing chopped carbon fiber bundles coated with a phenolic resin layer to obtain chopped carbon fiber bundles covered with a phenolic resin layer, and the ends of the chopped carbon fibers are not coated with phenolic resin layer, the resin layer is in a fully cured state, the thickness is 2mm, and the length of the chopped carbon fiber bundles covering the resin layer is 30mm;

[0074] Step 3: Proportionally weigh the chopped carbon fiber bundles and phenolic resin powder obtained...

Embodiment 3

[0085] Step 1: Take 6k continuous carbon fiber bundles and heat-treat them in an argon atmosphere furnace at 1300°C to remove metal ions and impurities on the surface, then use acetone and deionized water as cleaning agents to clean them until there is no glue on the surface, and finally clean them The continuous carbon fiber bundle is placed in an oven and dried to obtain a pretreated continuous carbon fiber bundle;

[0086] Step 2: passing the pretreated continuous carbon fiber bundles through the equipment for preparing chopped carbon fiber bundles coated with phenolic resin layers on the surface to produce 3 kinds of chopped carbon fiber bundles coated with phenolic resin layers on the surface,

[0087] a The two ends of the chopped carbon fiber are not covered with the phenolic resin layer and are in a semi-cured state, the thickness of the resin layer is 1 mm, and the length of the chopped carbon fiber bundle covered with the resin layer is 20 mm;

[0088] b One end of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com