Method for preparing zinc oleate

A technology of zinc oleate and oleic acid is applied in the preparation of carboxylates, carboxylates, organic compounds and other directions, which can solve the problems of easy oxidation of products, large amount of n-hexane, and difficulty in recycling, and avoid oxidation. , the effect of high reaction yield and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

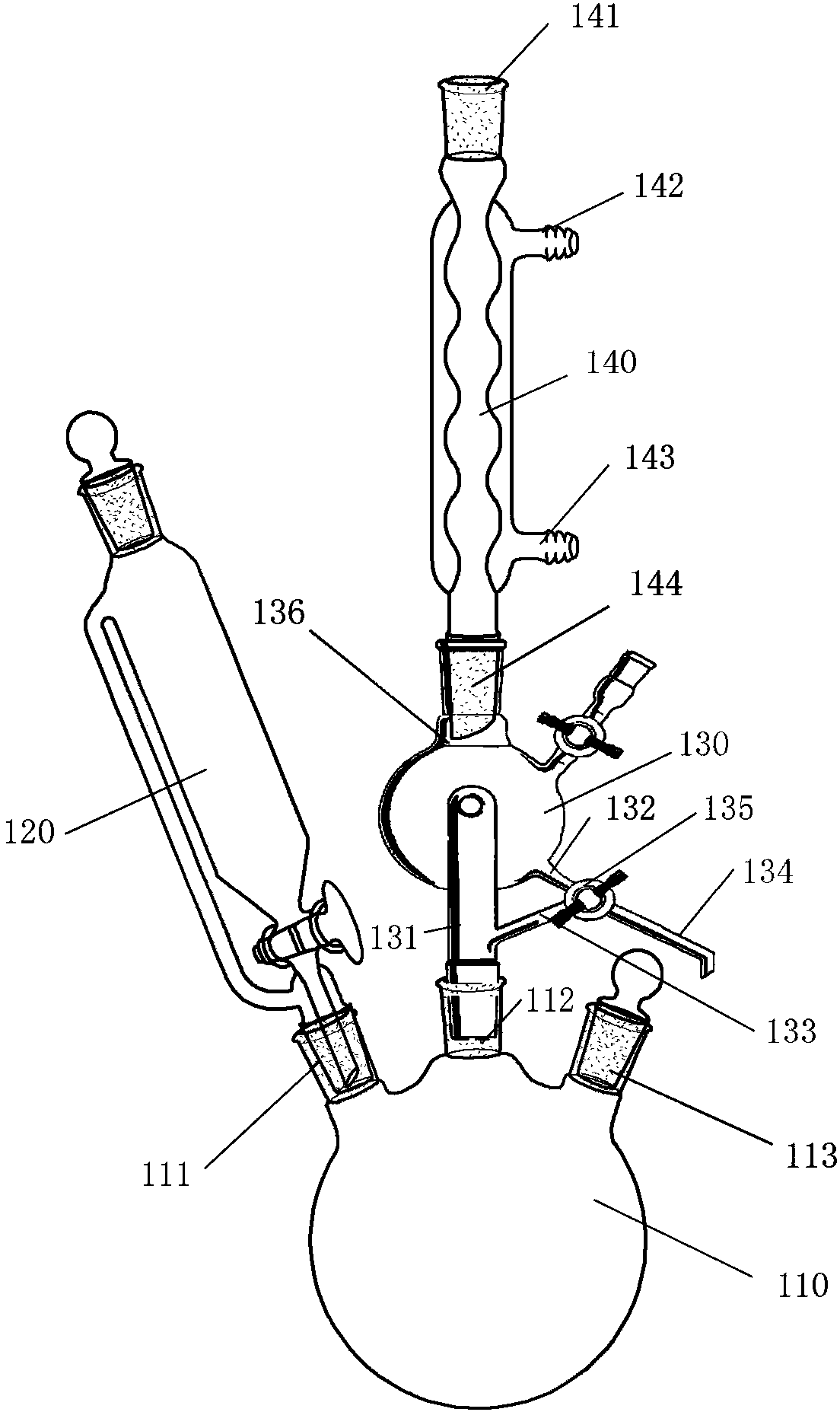

[0022] The preparation method of zinc oleate of the present invention adopts figure 1 The preparation device shown is carried out, and preparation device comprises a three-necked flask 110, a constant pressure funnel 120, a distillation ball 130, a condensation tube 140 and a ventilation device (not shown on the figure), constant pressure funnel 120 and distillation The balls 130 are respectively inserted into an opening of the three-necked flask 110 for connection, and the condenser tube 140 is inserted into the upper port of the distillation ball 130 for fixed connection.

[0023] The three-neck flask 110 includes a first opening 111, a second opening 112, and a third opening 113, and the third opening 113 is sealed with a bottle stopper.

[0024] The constant pressure funnel 120 is inserted into the first opening 111 and fixedly connected.

[0025] Distillation ball 130 comprises a steam channel 131, a liquid channel 132, a return port 133, a discharge port 134, a changeov...

Embodiment 1

[0036] Take 300g of oleic acid and 120g of zinc acetate into the reaction device, replace the air in the reaction device with nitrogen, turn the switch 135 until the return port 133 is unblocked, reflux at 100°C for 4 hours under stirring conditions, and then turn the changeover switch 135 to the discharge port 134 to be unblocked , steam out acetic acid and discharge from outlet 134, obtain acetic acid 164g altogether, take out the residual acetic acid in the three-necked flask 110 with aeration device, cool to 50 ℃, add 4200g n-hexane in the three-necked flask 110, cool down after fully dissolving, oil The crude zinc oleate product was separated out; the crude zinc oleate product was filtered and washed with water to remove the residual zinc acetate, and then the oleic acid in the crude zinc oleate product was washed away with n-hexane or acetone, followed by vacuum drying to obtain 303 g of zinc oleate finished product.

Embodiment 2

[0038] Take 200g of oleic acid and 90g of zinc acetate into the reaction device, replace the air in the reaction device with nitrogen, turn the switch 135 until the return port 133 is unblocked, reflux at 100°C for 4 hours under stirring conditions, and then turn the changeover switch 135 to the discharge port 134 to be unblocked , steam out the acetic acid and discharge it from the discharge port 134 to obtain 30 g of acetic acid altogether, extract the residual acetic acid in the three-necked flask 110 with a ventilation device, cool to 80° C., add 580 g of n-hexane in the three-necked flask 110, cool down after fully dissolving, oil The zinc oleate crude product is separated out; filter and wash the zinc oleate crude product to remove the zinc acetate remaining therein, then wash off the oleic acid in the zinc oleate crude product with n-hexane or acetone, and then vacuum dry to obtain 176g of zinc oleate finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com