A low-cost high-purity green nanocrystalline battery grade anhydrous fepo 4 the preparation method of

A green and environmentally friendly nanocrystalline technology, applied in nanotechnology, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of equipment investment, high cost of sewage treatment, complicated co-precipitation process, large investment in equipment, etc., and achieve low price , fine workmanship and small investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

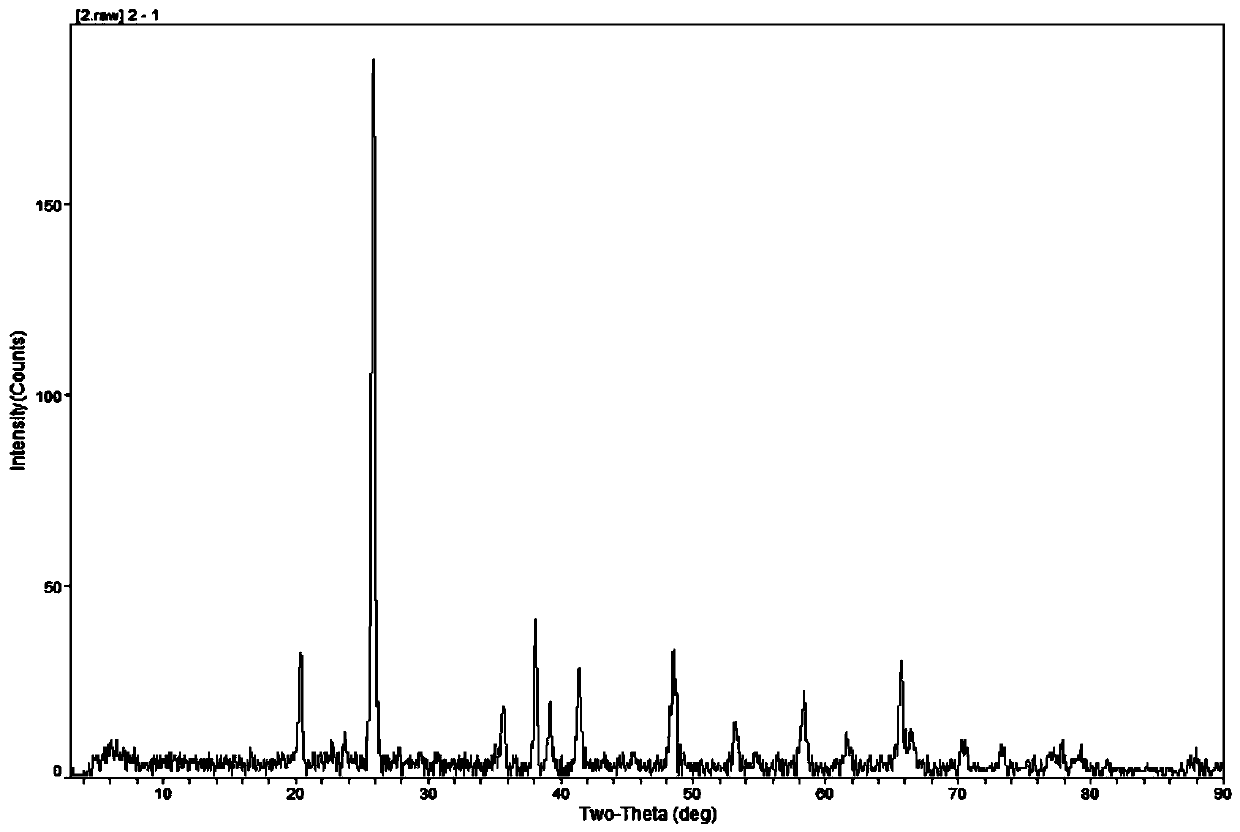

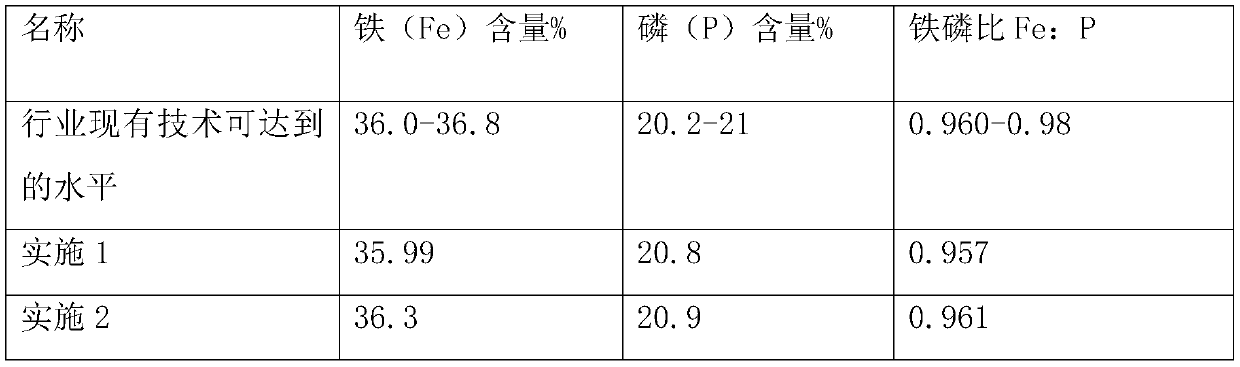

[0033] A low-cost, high-purity, green and environmentally friendly nanocrystalline battery-grade anhydrous FePO 4 The preparation method, described method comprises the following steps:

[0034] (1) 115 grams of 85% H 3 PO 4 1. Dissolve 60g of oxalic acid in pure water, add 56g of Fe powder with a particle size of less than 100μm under nitrogen protection, stir and soak for 20 hours, then add the soaked raw materials to a high-energy mill and grind for 45 hours. Stirring speed: 450 rpm, nitrogen volume 90ml per minute.

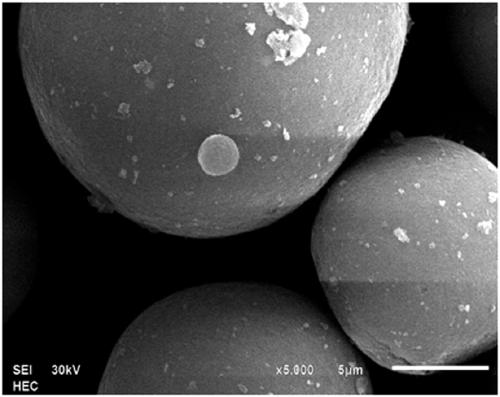

[0035] (2) The ground material is spray-dried in a centrifugal sprayer to obtain spherical particles of 15-35 μm.

[0036] (3) The spray-dried spherical particle powder is fed into pure oxygen (purity is 99%-99.99% pure oxygen, and the flow rate of pure oxygen is 90ml per minute) at 400°C for calcination treatment, and heat preservation for 13 hours;

[0037] (4) The above-mentioned calcined material is subjected to airflow pulverization to obtain a spheri...

Embodiment 2

[0039] A low-cost, high-purity, green and environmentally friendly nanocrystalline battery-grade anhydrous FePO 4 The preparation method, described method comprises the following steps:

[0040] (1) 120 grams of 85% H 3 PO 4 1. Dissolve 65g of oxalic acid in pure water, add 58 g of Fe powder with a particle size of less than 100μm under nitrogen protection, stir and soak for 24 hours, then add the soaked raw materials into a high-energy mill and grind for 48 hours. Stirring speed: 650 rpm, nitrogen The volume is 100ml per minute.

[0041] (2) The ground material is spray-dried in a centrifugal sprayer to obtain spherical particles of 15-35 μm.

[0042] (3) The spray-dried spherical particle powder is calcined at 500° C. in a sintering furnace fed with pure oxygen (purity is 99%-99.99% pure oxygen, and the flow rate of pure oxygen is 110 ml per minute), and it is kept warm for 13 Hour;

[0043] (4) The above-mentioned calcined material is subjected to airflow pulverization t...

Embodiment 3

[0045] A low-cost, high-purity, green and environmentally friendly nanocrystalline battery-grade anhydrous FePO 4 The preparation method, described method comprises the following steps:

[0046] (1) 120 grams of H3PO with a concentration of 85% 4 Dissolve 70g of oxalic acid in pure water, add 60g of Fe powder with a particle size of less than 100μm under the protection of nitrogen to carry out ball milling reaction for 50h, stirring speed: 750 rpm, nitrogen volume 135ml per minute.

[0047] (2) The ground material is spray-dried in a centrifugal sprayer to obtain spherical particles of 35 microns.

[0048] (3) The spray-dried spherical particle powder is calcined at 600°C in a sintering furnace fed with pure oxygen (purity is 99%-99.99% pure oxygen, and the flow rate of pure oxygen is 170ml per minute), and it is kept warm for 13 Hour;

[0049] (4) The above-mentioned calcined material is subjected to airflow pulverization to obtain a spherical lithium iron phosphate precur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com