Forming tool of cooling strip of PTC heat-sensitive material heating device

A technology for heating devices and forming tooling, applied to workpiece clamping devices, manufacturing tools, etc., can solve problems such as customer complaints, and achieve the effects of convenient manipulation, easy control, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

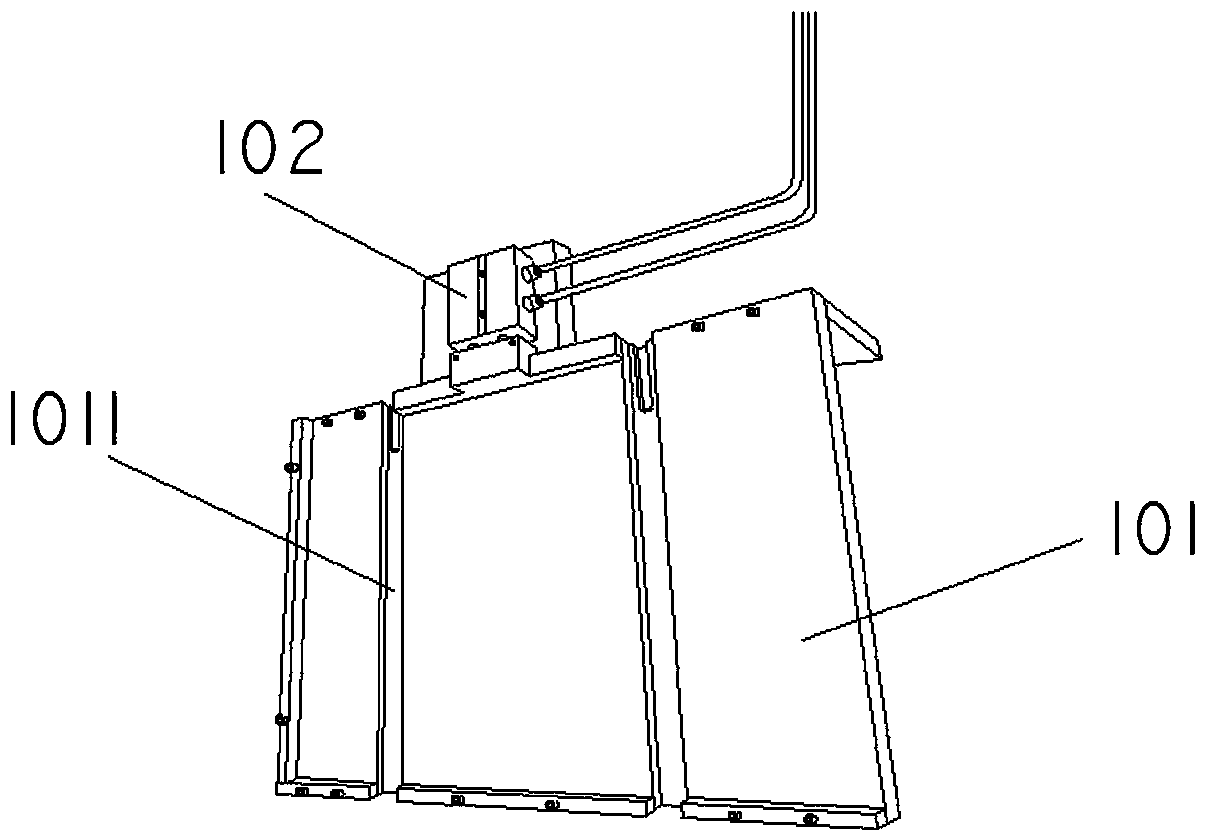

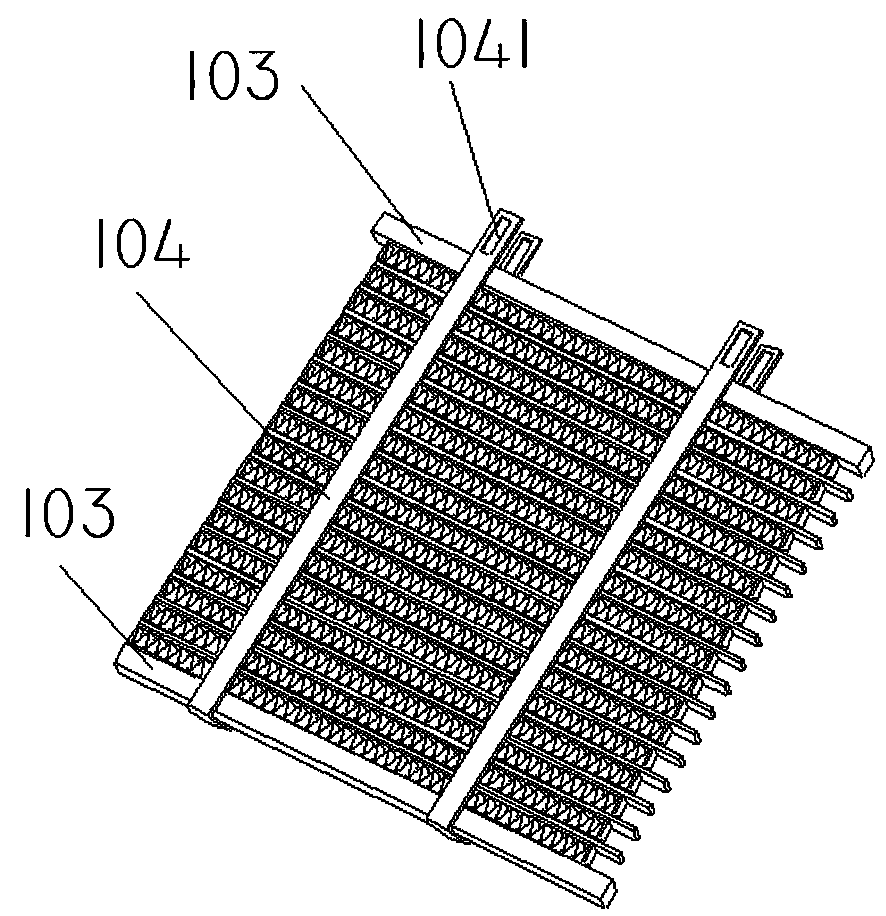

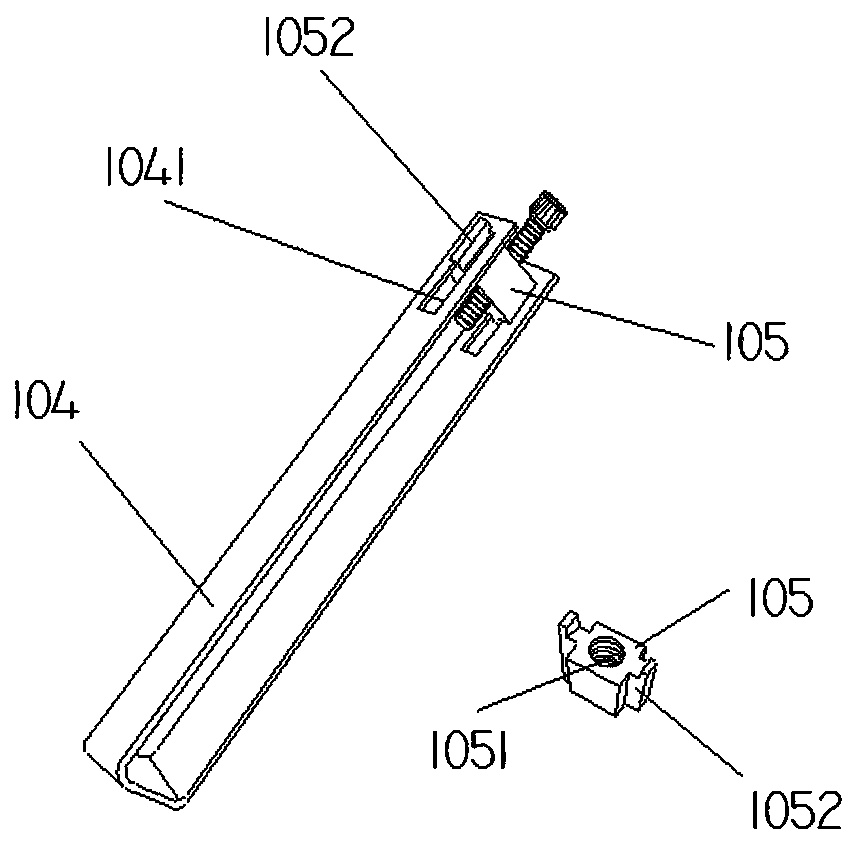

[0017] Such as Figure 1~4 As shown, the forming tooling of the heat dissipation strip of the PTC heat-sensitive material heating device includes a platen 101 for placing the heat dissipation strip, a positioning frame for clamping and fixing the heat dissipation strip; the platen 101 is L-shaped along the width direction after processing, and its There is a rectangular groove 1011 on the surface in the width direction, and there is no less than one set of forming fastening cylinders 102 on one side in the length direction. Metal strip 103 and no less than two groups of sliding fasteners; further, the sliding fasteners are composed of U-shaped metal sheets 104 and connecting fixtures 105, and the length of the two wings of the U-shaped metal sheets 104 is the same as The width of the platen 101 is the same, the wing width is 8-35 mm, and the wall thickness is 4-20 mm. The distance between the two wings of the connected part of the bottom of the U-shaped metal sheet 104 is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com