Built-in sorbent floating head type adsorbent bed refrigeration unit

A refrigeration unit and adsorption bed technology, applied in the field of adsorption refrigeration, can solve the problems of reduced adsorption refrigeration performance, inability to reduce mass transfer resistance, and easy leakage, etc., to achieve strong adaptability to alternating thermal stress, strong industrial application value, and guarantee The effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

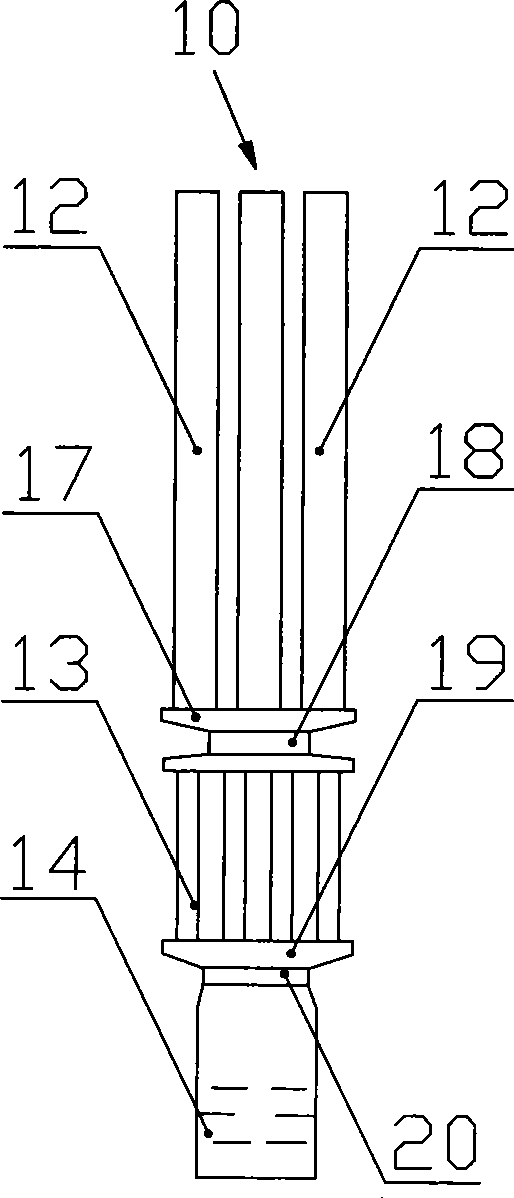

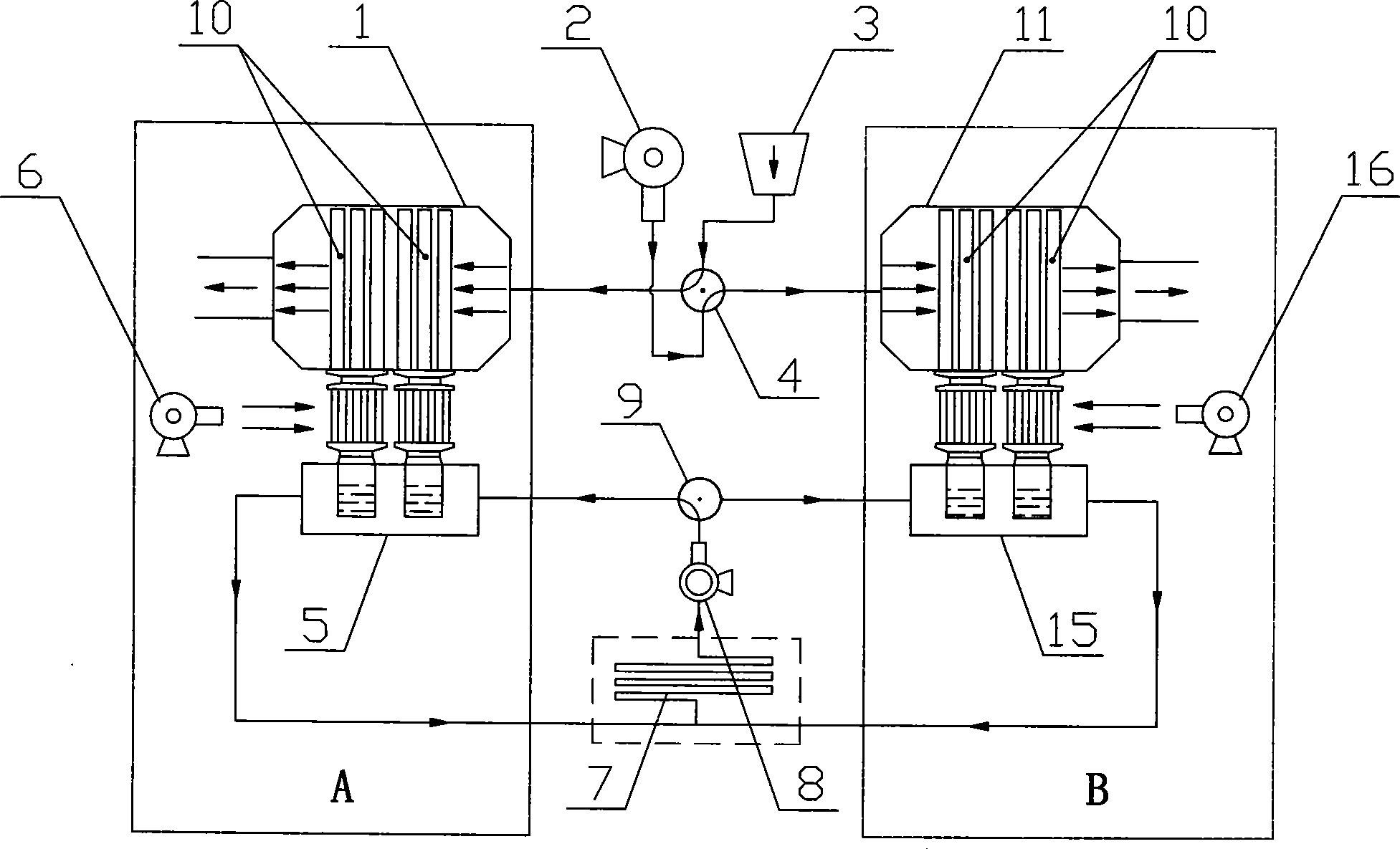

[0019] In order to reduce the thermal stress on the tube sheet of the adsorption bed and improve the reliability of the system, the present invention combines the technical advantages of each adsorption refrigeration unit and proposes a new type of adsorption bed refrigeration unit with a built-in adsorbent floating head structure, such as figure 1 Shown: a built-in adsorbent floating head type adsorption bed refrigeration unit 10, the built-in adsorbent floating head type adsorption bed refrigeration unit 10 includes an adsorption bed 12 connected in sequence, a heat-insulated and connected closed body 17, a condenser 13, an adiabatic connected and sealed body body 19 and evaporator 14;

[0020] The adsorption bed 12 is composed of six outer finned tubes with an outer diameter of 20mm, and the six outer finned tubes are evenly distribute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com