Collective thermal-arrest pipe with double layer glasses

A double-glazed, heat-pipe technology, applied in the field of solar energy applications, can solve problems such as easy gas leakage, rupture, and safety impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

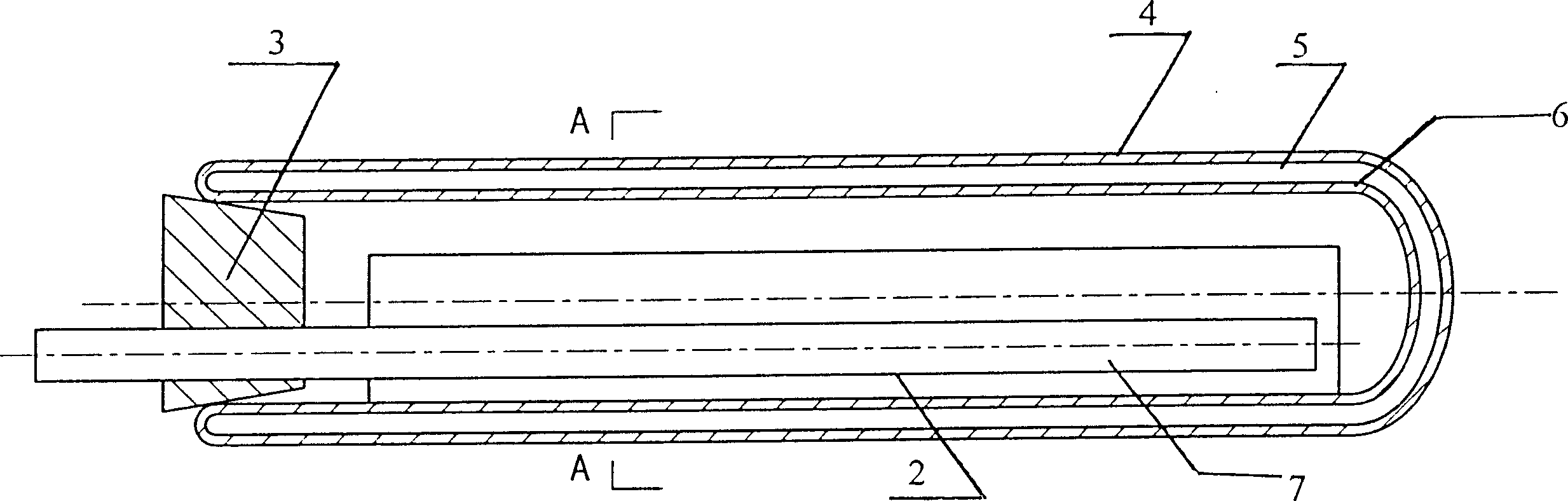

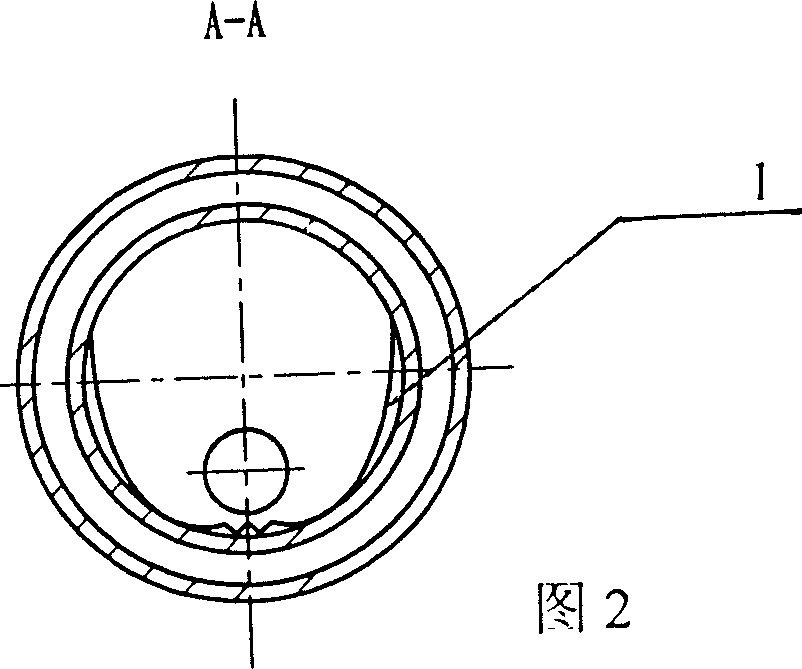

[0007] Referring to the accompanying drawings, the structure is that the inner and outer layers of glass tubes 6 and 4 form a vacuum glass sleeve, the bottom of the concentrating plate 1 is W-shaped, the concentrating plate 1 is inserted into the cavity in the inner tube of the vacuum glass sleeve, and the surface is coated with The heating section of the heat pipe 7 of the selective absorption coating 2 is placed at the focal line of the condensing plate 1 , and a plug 3 is used to seal the space between the heat pipe 7 and the vacuum glass sleeve.

[0008] Working process: sunlight passes through the vacuum glass casing, after being reflected and focused by the concentrating plate 1, it is absorbed by the selective absorbing coating 2 on the surface of the heating section of the heat pipe 7, heating the working fluid in the heat pipe 7, and the working fluid in the tube is vaporized to reach The cooling section of the heat pipe 7 transfers heat to the cooling substance outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com