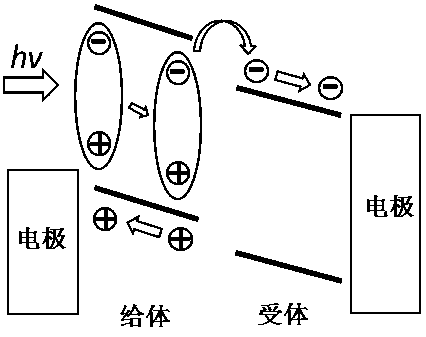

An ordered heterojunction photovoltaic device and a preparation method thereof

A photovoltaic device and heterojunction technology, which is applied in the direction of organic semiconductor devices, semiconductor/solid-state device manufacturing, photovoltaic power generation, etc., can solve the problems that affect the conversion efficiency of photovoltaic devices, complex preparation process, poor regularity, etc., to reduce charge recombination probability, simplification of photovoltaic device structure, and reduction of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

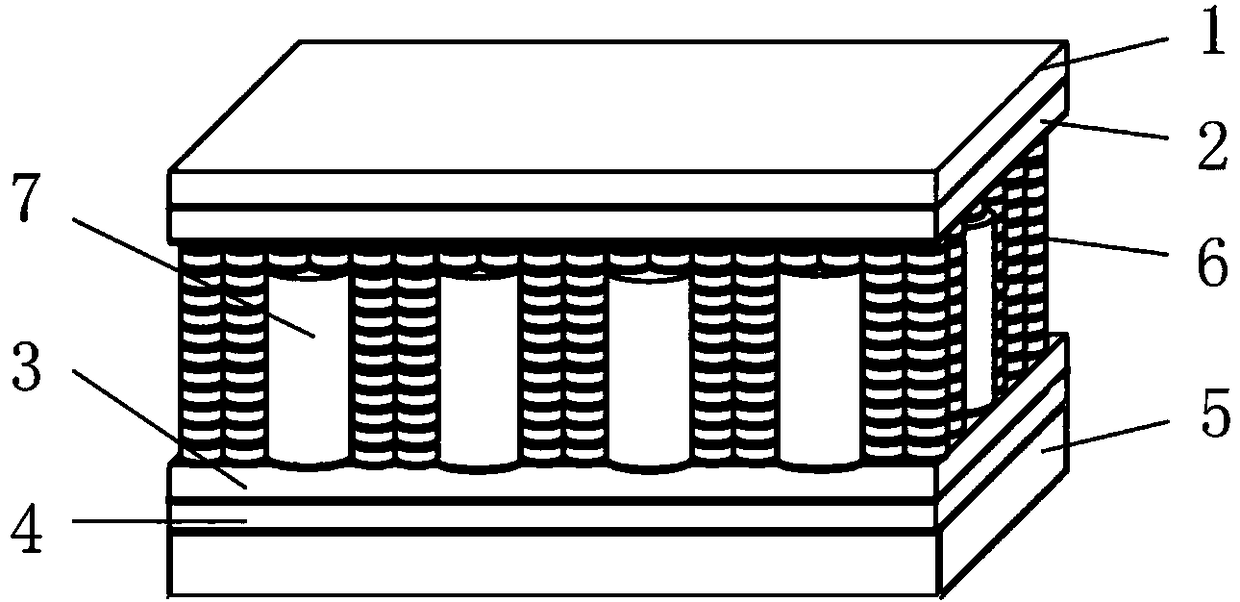

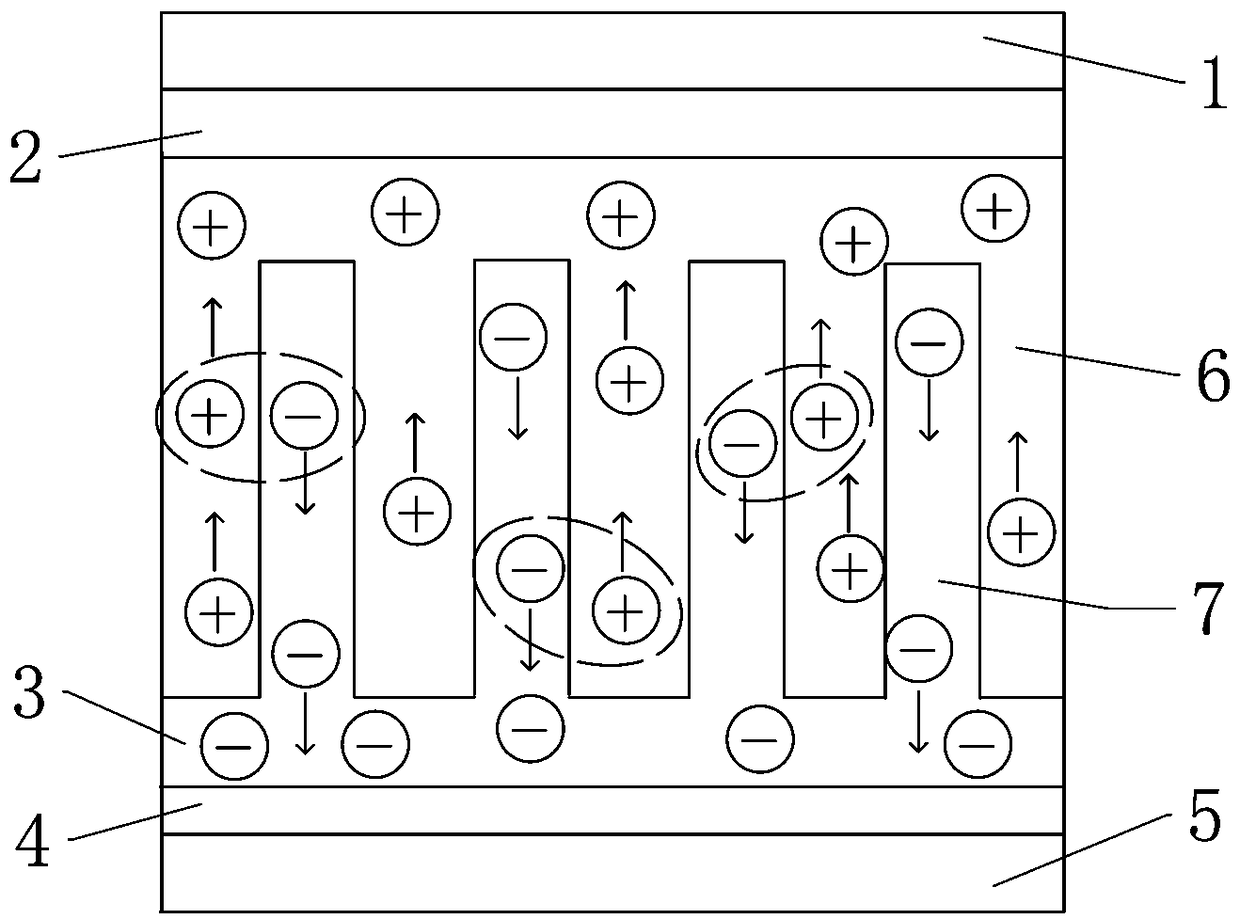

[0038] An ordered heterojunction photovoltaic device, from top to bottom is a cathode layer 1, an interface modification layer 2, a photovoltaic active layer, a hole blocking layer 3, an anode layer 4 and a substrate 5. The negative electrode layer 1 is an Au film with a thickness of 100 nm; the interface modification layer 2 is a MoO film with a thickness of 10 nm. 3 Thin film; The photovoltaic active layer includes an organic layer 6 and an inorganic layer; The hole blocking layer 3 is a ZnO thin film with a thickness of 10nm; The positive electrode layer 4 is an FTO electrode; The substrate 5 is a glass substrate.

[0039]The inorganic layer is an ordered ZnO nanorod array perpendicular to the substrate 5, the organic layer 6 fills and covers the ZnO nanorod array, and the top surface of the organic layer 6 is in contact with the substrate. 5 in parallel, the organic layer 6 is made of perylene liquid crystal PE-TP, the nanorods in the ZnO nanorod array have a height of 400...

Embodiment 2

[0050] An ordered heterojunction photovoltaic device comprises a cathode layer 1, an interface modification layer 2, a photovoltaic active layer, a hole blocking layer 3, an anode layer 4 and a substrate 5 from top to bottom. The negative electrode layer 1 is an Au film with a thickness of 150 nm; the interface modification layer 2 is a MoO film with a thickness of 50 nm. 3 Thin film; The photovoltaic active layer includes an organic layer 6 and an inorganic layer; The hole blocking layer 3 is a ZnO thin film with a thickness of 30nm; The positive electrode layer 4 is an FTO electrode; The substrate 5 is a glass substrate.

[0051] The inorganic layer is an ordered ZnO nanorod array perpendicular to the substrate 5, the organic layer 6 fills and covers the ZnO nanorod array, and the top surface of the organic layer 6 is in contact with the substrate. 5 parallel, the organic layer 6 is made of perylene liquid crystal PE-TP, the nanorods in the ZnO nanorod array have a height of...

Embodiment 3

[0054] An ordered heterojunction photovoltaic device, from top to bottom is a cathode layer 1, an interface modification layer 2, a photovoltaic active layer, a hole blocking layer 3, an anode layer 4 and a substrate 5. The negative electrode layer 1 is an Au film with a thickness of 150 nm; the interface modification layer 2 is a MoO film with a thickness of 50 nm. 3 Thin film; The photovoltaic active layer includes an organic layer 6 and an inorganic layer; The hole blocking layer 3 is a ZnO thin film with a thickness of 30nm; The positive electrode layer 4 is an FTO electrode; The substrate 5 is a glass substrate.

[0055] The inorganic layer is an ordered ZnO nanorod array perpendicular to the substrate 5, the organic layer 6 fills and covers the ZnO nanorod array, and the top surface of the organic layer 6 is in contact with the substrate. 5 in parallel, the organic layer 6 is made of perylene liquid crystal PE-TP, the nanorods in the ZnO nanorod array have a height of 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com