Calcium carbonate isolation solution for large-porosity easy-to-leak oil gas layer well cementation

A calcium carbonate, oil and gas layer technology, applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as pollution damage to oil and gas layers, and achieve the effects of improving interface cleanliness, good scouring effect, and wide application range of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific examples, but the following examples do not limit the present invention in any way.

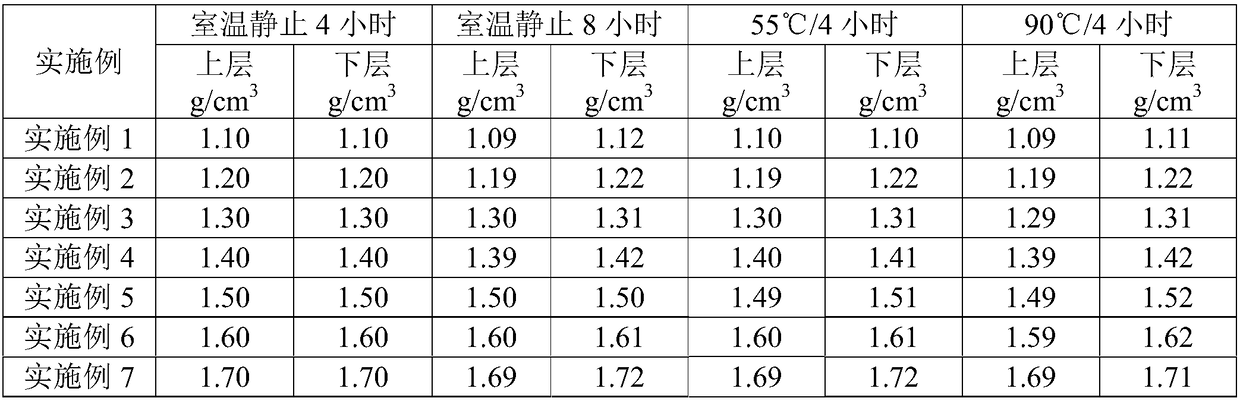

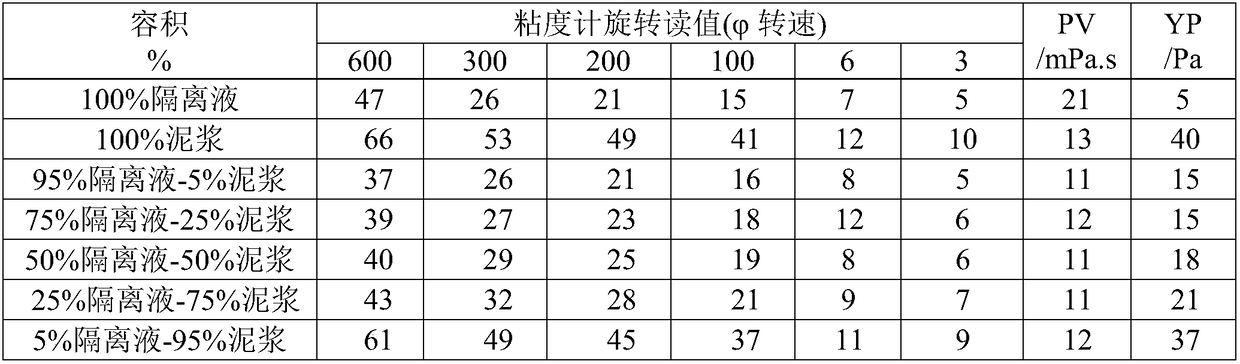

[0017] The spacer fluid products of Examples 1-7 were prepared according to the data given in Table 1-1 below.

[0018] Table 1-1:

[0019]

[0020] The calcium carbonate used in above-mentioned embodiment 1~7 is commercially available light calcium carbonate, and suspension stabilizer is the suspension stabilizer that the model of Tianjin Zhongyou Boxing Engineering Technology Co., Ltd. produces is BCS-040S, and diluent is Tianjin Zhongyou Bo The diluent produced by Star Engineering Technology Co., Ltd. is BCS-021L, the drag reducer is CF40S sulfonated aldehyde and ketone condensate drag reducer produced by Tianjin Zhongyou Boxing Engineering Technology Co., Ltd., and the flushing agent is Tianjin Zhongyou Bo The type BCS-010L fatty acid glyceride flushing agent produced by Star Engineering Technolo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com