Polyethyleneimine based chloramines type antibacterial cellulose membrane, preparation method and application

A polyethyleneimine-based chloramine-type, polyethyleneimine technology, applied in the field of polymer material preparation, to achieve the effects of environmental protection in the preparation process, mild reaction conditions, and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A preparation method of polyethyleneimine chloramine type antibacterial cellulose film, comprising the following steps:

[0031] Step 1: preparing a cellulose solution with a mass concentration of 5wt%;

[0032] Step 2: After defoaming the cellulose solution prepared in step 1, casting a film on the substrate, washing after solidification to obtain a regenerated cellulose gel film;

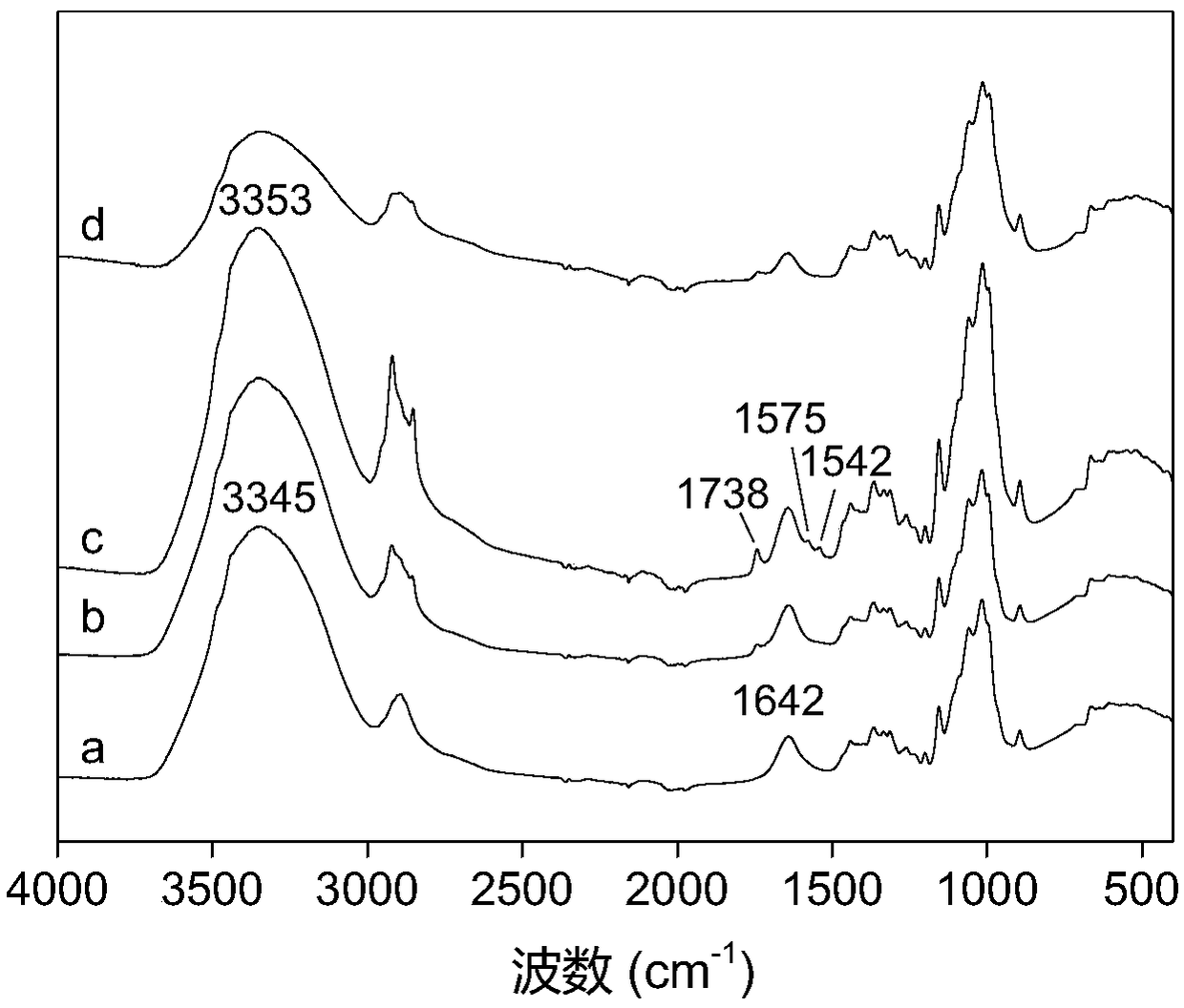

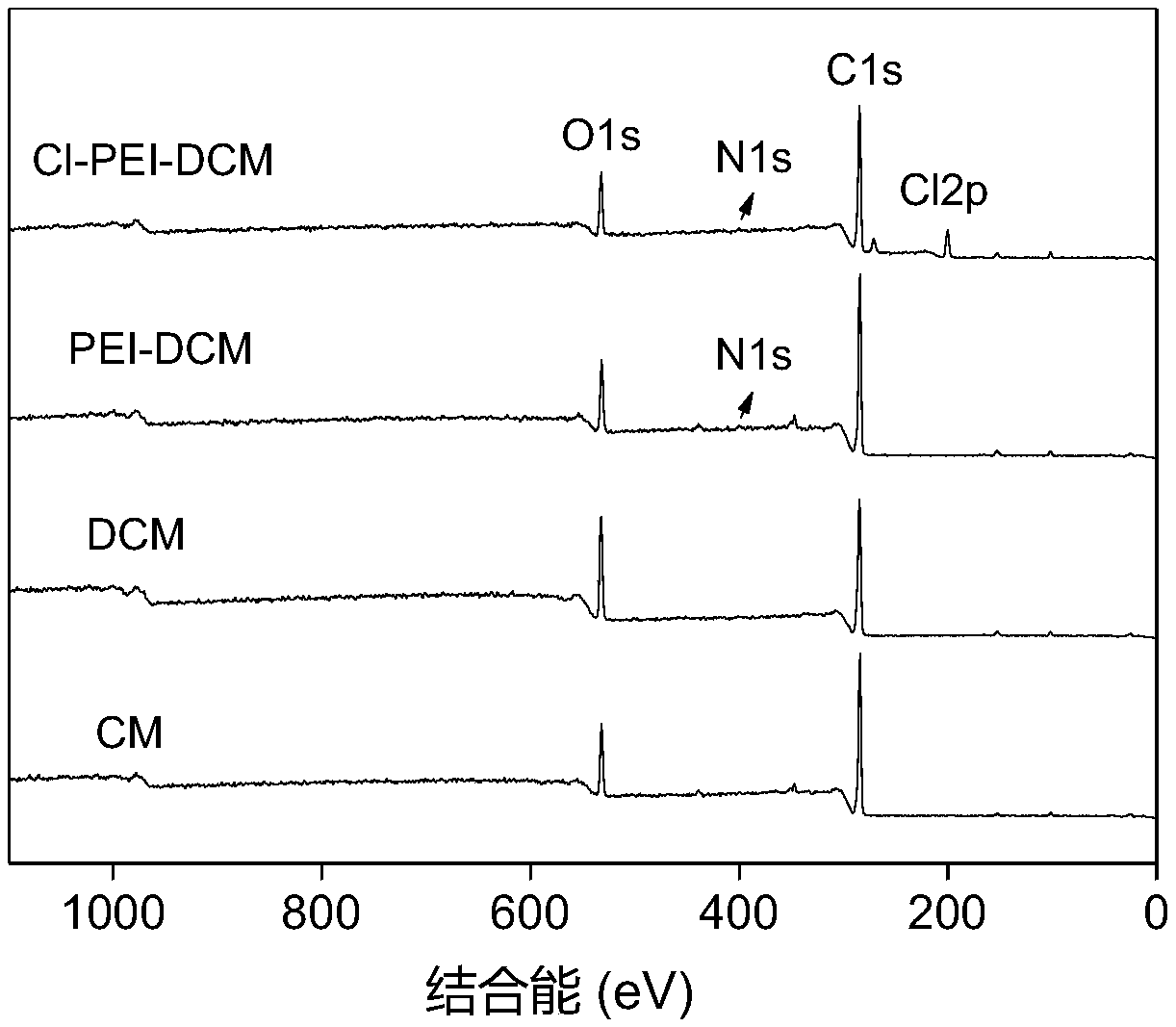

[0033] Step 3: oxidizing the regenerated cellulose gel film obtained in step 2 with an aqueous solution of sodium periodate to obtain a dialdehyde cellulose gel film with an aldehyde group content of 1 to 3 mmol / g;

[0034] Step 4: immersing the dialdehyde cellulose gel film obtained in step 3 in a polyethyleneimine aqueous solution for grafting reaction to obtain a polyethyleneimine grafted cellulose film;

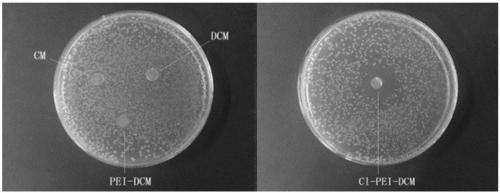

[0035] Step 5: After chlorinating the polyethyleneimine-grafted cellulose film obtained in step 4, a polyethyleneimine-based chloramine-type antibacterial cellulose film is obtained. ...

Embodiment 1

[0044] Prepare polyethyleneimine-based chloramine-type antibacterial cellulose membranes according to the following steps:

[0045] Step 1: Add 5 g of cellulose to 95 g of TBAH / DMSO solvent, stir and dissolve to obtain a 5 wt % cellulose solution; the TBAH / DMSO solvent is a mixture of 50 wt % TBAH aqueous solution and DMSO in a mass ratio of 1:4 liquid;

[0046] Step 2: After defoaming the cellulose solution prepared in step 1, casting the film on the substrate, placing it in the air to gel, and eluting the solvent with water to obtain a regenerated cellulose gel film (CM);

[0047] Step 3: Put 2 g of the regenerated cellulose gel film obtained in Step 2 into a sodium periodate solution with a concentration of 1 g / L and pH=5, oxidize it at 25°C for 6 hours, and then wash it with water to obtain dialdehyde fibers plain gel membrane (DCM);

[0048] Step 4: Immerse the dialdehyde cellulose gel film obtained in step 3 in the PEI solution with a concentration of 0.05% and pH=10, ca...

Embodiment 2

[0056] Prepare polyethyleneimine-based chloramine-type antibacterial cellulose membranes according to the following steps:

[0057] Step 1: Add 5 g of cellulose to 95 g of TBAH / DMSO solvent, stir and dissolve to obtain a 5 wt % cellulose solution; the TBAH / DMSO solvent is a mixture of 50 wt % TBAH aqueous solution and DMSO in a mass ratio of 1:4 liquid;

[0058] Step 2: after degassing the cellulose solution prepared in step 1, casting a film on the substrate, placing it in the air to gel, and eluting the solvent with water to obtain a regenerated cellulose gel film;

[0059] Step 3: Put 2 g of the regenerated cellulose gel film obtained in Step 2 into a sodium periodate solution with a concentration of 1 g / L and pH=5, oxidize it at 25°C for 6 hours, and then wash it with water to obtain dialdehyde fibers plain gel film;

[0060] Step 4: Immerse the dialdehyde cellulose gel film obtained in step 3 into the PEI solution with a concentration of 1% and pH=9, carry out grafting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com