Fiber laminated structures for reinforcements, pultruded profiles

A fiber lay-up and reinforcing material technology is applied to the fiber lay-up structure of reinforcing materials and pultruded profiles. It can solve the problems of not easy delamination, insufficient longitudinal split resistance, insufficient interlayer bonding ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

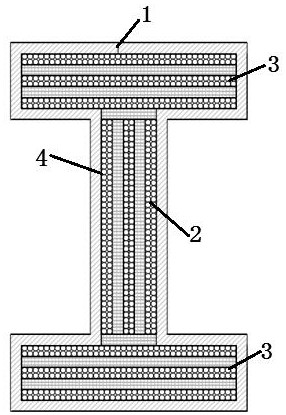

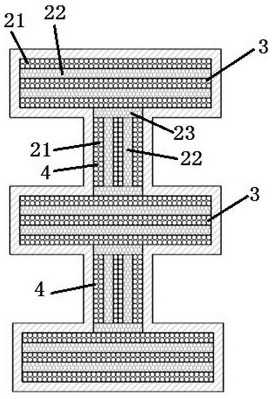

[0025] Combine below Figure 1 to Figure 2 Embodiments of the present invention are described in detail.

[0026] The fiber lay-up structure of the reinforcing material includes a laminated fiber lay-up 2 and a fiber wrapping layer 1, which is characterized in that the fiber wrapping layer 1 completely wraps the outer surface of the fiber lay-up layer 2, and the fiber wrapping layer 1 The thickness is greater than the thickness of any layer in the fiber layup 1 .

[0027] As shown in the figure, in the fiber lay-up structure of the reinforced material, the fiber lay-up layer is used to completely wrap the fiber lay-up layer, and the thickness of the fiber wrapping layer is greater than the thickness of any layer of fiber lay-up, so that the fiber lay-up structure forms a whole, and the fiber lay-up layer The layered structure has uniform longitudinal and transverse mechanical properties after pultrusion. During the long-term bearing process, the profile is not easy to delamin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com