Preparation method for thermosetting phenolic resin tensile sample with high solvent content

A technology of phenolic resin and solvent content, applied in the field of composite materials, can solve the problems of phenolic resin matrix brittleness, difficulty, casting body fracture, etc., achieve good mechanical properties and improve the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

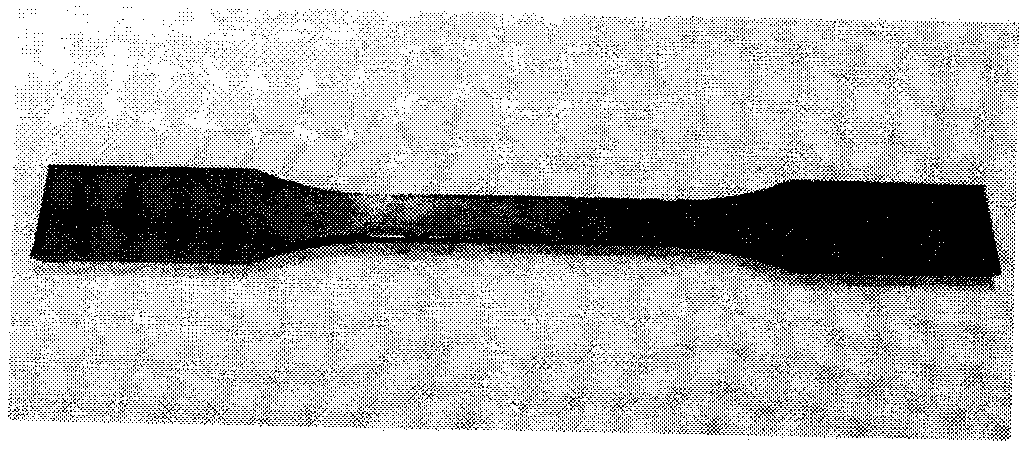

Image

Examples

example 1

[0048] The preparation process of the thermosetting phenolic resin tensile specimen casting body is as follows: Take 80g of magnesium phenolic resin and slowly heat it up from room temperature to 90°C at a heating rate of 2°C / min. 8h, the solid content reaches 60%, and the curing degree reaches 65%. Put the phenolic resin in the semi-gel state into the freezer and keep it frozen at minus 10°C for 8 hours. The stretching mold coated with the release agent is preheated at a constant temperature of 120°C for 3 hours, and then take 18g of powdered phenolic resin Spread the phenolic resin evenly into the drawing mold, fully melt at 120°C for 6 hours, close the mold and pressurize, raise the temperature to 160°C at a rate of 3°C / min under a pressure of 10MPa, cure at a constant temperature of 10h, and then disassemble at 160°C Open the mold, take out the sample, and continue to place the sample in an oven at a constant temperature of 180°C for 12 hours until it is completely cured. ...

example 2

[0051] The preparation process of the thermosetting phenolic resin tensile specimen casting body is as follows: Take 100g of magnesium phenolic resin and slowly heat it up from room temperature to 100°C at a heating rate of 4°C / min. After 6 hours, the solid content reached 68%, and the curing degree reached 69%. Put the phenolic resin in the semi-gel state into the freezer, keep it frozen at minus 15°C for 5 hours, preheat the stretching mold coated with the release agent for 6 hours at a constant temperature of 100°C, and then add 20g of powdered phenolic resin Spread the phenolic resin evenly into the drawing mold, fully melt at a constant temperature of 100°C for 12 hours, close the mold and pressurize, raise the temperature to 150°C at a rate of 2°C / min under a pressure of 10MPa, cure at a constant temperature for 15 hours, and open the mold at 150°C , Take out the sample and put it in the oven at 180°C for 6h until it is completely cured, process and polish it, and finall...

example 3

[0054] The preparation process of the thermosetting phenolic resin tensile specimen casting body is as follows: Take 120g of aminophenolic resin and slowly heat it up from room temperature to 95°C at a heating rate of 3°C / min. h, the solid content reaches 60%, and the curing degree reaches 70%. Put the phenolic resin in the semi-gel state into the freezer and keep it frozen at minus 8°C for 10 hours. The stretching mold coated with the release agent is preheated at a constant temperature of 110°C for 5 hours, and then the powdered phenolic resin The resin is uniformly spread into the drawing mold, fully melted at a constant temperature of 110°C for 10 hours, the mold is closed and pressurized, the temperature is raised to 170°C at a rate of 2°C / min under a pressure of 10MPa, the temperature is cured for 9 hours, and the mold is opened at a temperature of 170°C. Take out the sample and put it in an oven at 190°C for 5 hours until it is completely cured, process and polish it, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com