Environment-friendly wood floor based on waste wood

A wood floor, environmentally friendly technology, applied in the direction of wood veneer joining, wood treatment, wood heating, etc., can solve the problems of environmental degradation, waste of resources, shrinking forest area, etc., to achieve the effect of long life and ensure toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1, discarded Chinese fir

[0040]An environment-friendly wooden floor prepared based on waste wood, including waste Chinese fir treatment process and environment-friendly wood floor molding process, wherein the waste Chinese fir treatment process includes the following steps:

[0041] Step 1. Classification: the waste wood is judged by the characteristics of the Chinese fir in the structure, and the Chinese fir is classified and placed;

[0042] Step 2. Remove impurities: The impurities on the discarded fir include iron nails, paint surface and plastic buckle. The iron nails and plastic buckle are removed by screwing and crushing the wood, and the paint surface is removed by sharpening 1-3mm;

[0043] Step 3. Axial cutting: place the discarded fir in the axial direction, and have a cutting tool to cut the fir axially, so that the cross section of the fir is within 20×20mm;

[0044] Step 4. Air knife derotation: Use an air knife nozzle with an aperture of 1mm...

Embodiment 2

[0065] Embodiment 2, discarded pine wood

[0066] An environment-friendly wood floor prepared based on waste wood, including waste pine wood treatment process and environment-friendly wood floor molding process, differs from Example 1 in that it is kept at about 100°C for 20 minutes in ultra-high temperature sterilization, and then the temperature is raised to 320°C. Keep the temperature for 20 hours and take it out; in step A, it takes 3 hours to cook the pine wood, and in step B, the pine wood is soaked in nitric acid solution for 15 minutes; The temperature of the box is maintained at 70°C for 1 hour; the pressure in step S4 is 4 MPa, and the hot pressing is continued for 60 seconds; the speed of the mixer in step S3 is 10 r / min.

Embodiment 3

[0067] Embodiment 3, waste poplar

[0068] An environment-friendly wooden floor prepared based on waste wood, including waste poplar wood treatment process and environment-friendly wood floor molding process, the difference from Example 1 is that it is kept at about 100°C for 13 minutes in ultra-high temperature sterilization, and then the temperature is raised to 280°C , keep the temperature for 16 hours and take it out; in step A, it takes 3 hours to cook the poplar, and in step B, the poplar is soaked in nitric acid solution for 15 minutes; The temperature of the two temperature boxes is kept at 75° C. for 1 hour; the pressure in step S4 is 3.2 MPa, and the hot pressing is continued for 58 seconds; the speed of the mixer in step S3 is 12 r / min.

PUM

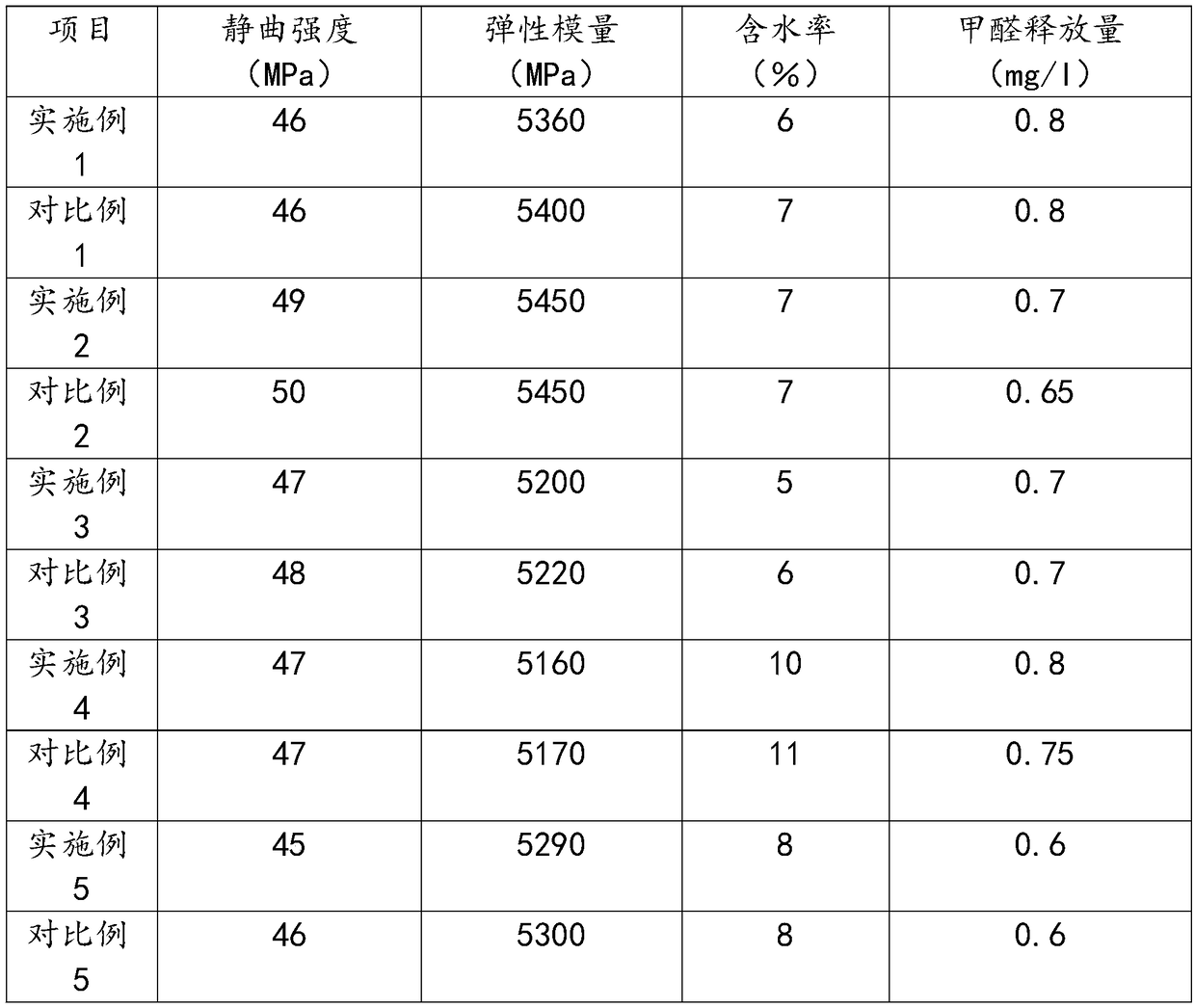

| Property | Measurement | Unit |

|---|---|---|

| Static bending strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Static bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com