Chip-free rotating and cutting machine

A technology of rotary cutting machine and cutting mechanism, which is applied in the direction of metal processing machinery parts, clamping, supporting, etc. It can solve the problems of uneven force on the blade, difficult adjustment of operation, and deformation of the incision, so as to achieve smooth cutting surface and ensure concentricity , the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

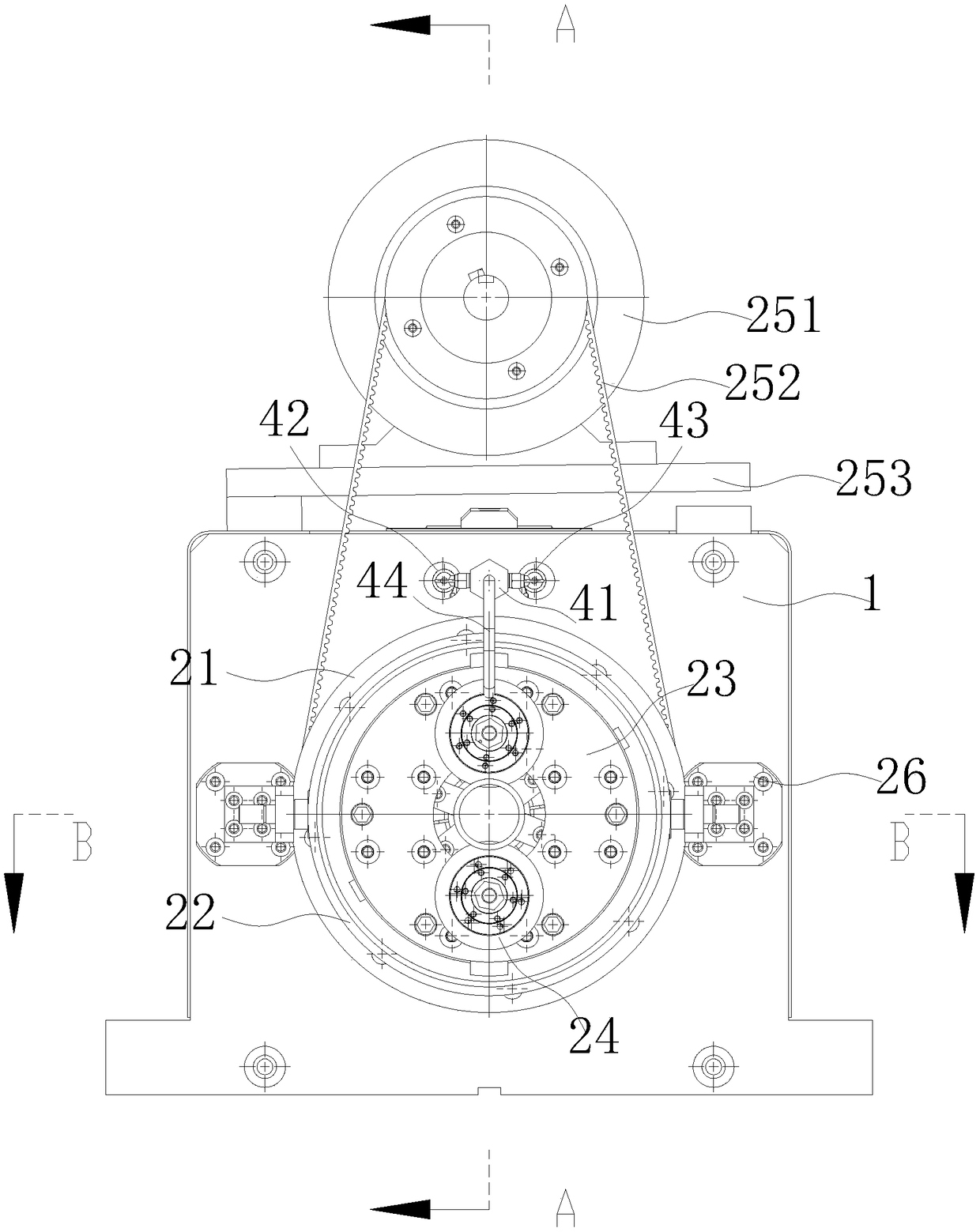

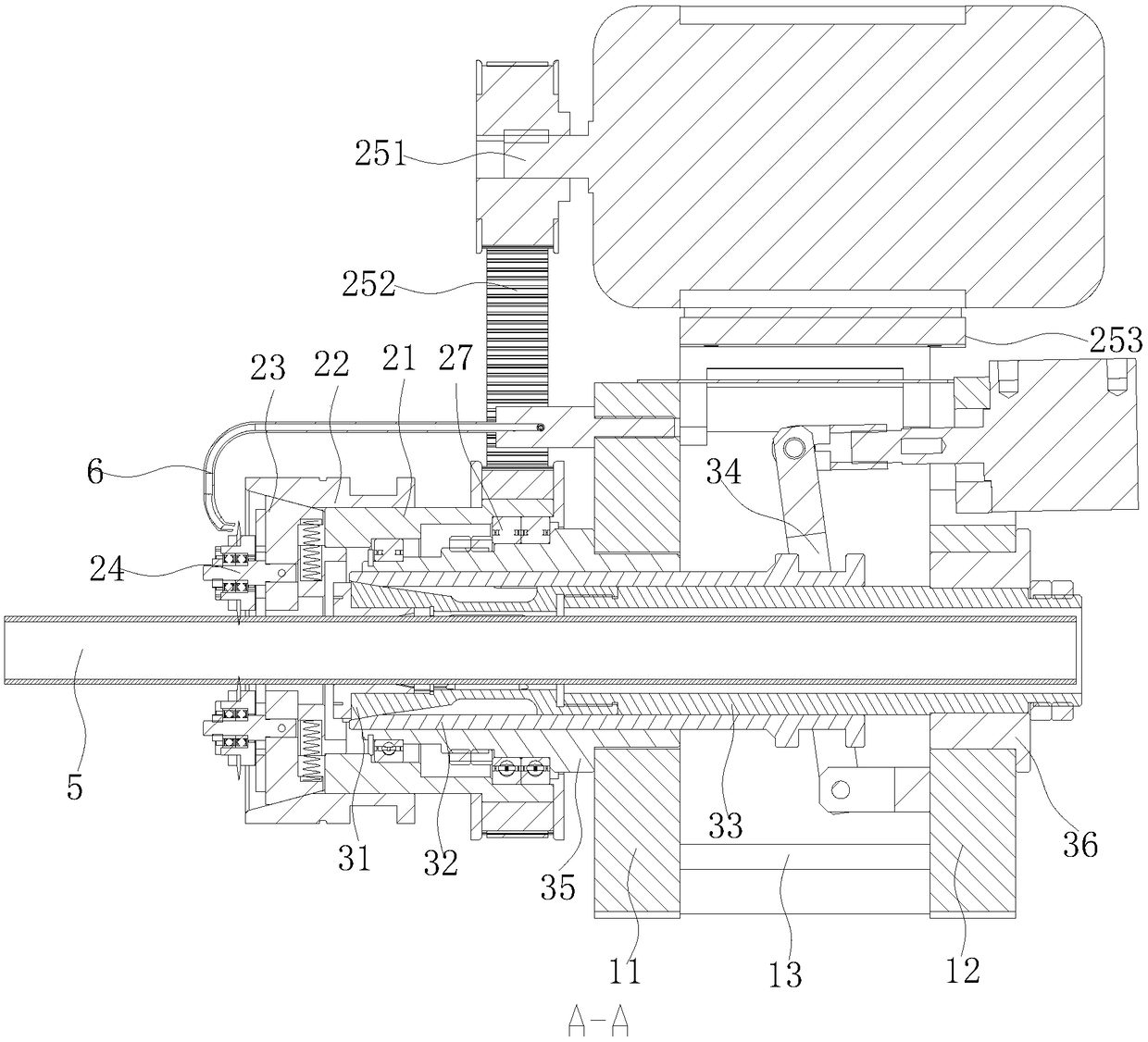

[0037] Figure 1-9Schematically shows a chipless rotary cutting machine according to an embodiment of the present invention, including a frame 1, a cutting device 2 and a clamping device 3, the cutting device 2 and the clamping device 3 are all installed on the frame 1, The frame 1 includes a first mounting plate 11 and a second mounting plate 12, the first mounting plate 11 and the second mounting plate 12 are balancedly arranged, the first mounting plate 11 and the second mounting plate 12 are fixedly connected by four fixed shafts 13, Both the first mounting plate 11 and the second mounting plate 12 are provided with mounting holes, and the two mounting holes are coaxially arranged, and the front and rear ends of the clamping device 3 are respectively fixedly installed in the two mounting holes. The cutting device 2 includes a transmission sleeve 21, an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com