Sand mold steel casting equipment

A steel casting and equipment technology, applied in casting molding equipment, metal processing equipment, casting molds, etc., can solve problems affecting product quality, demoulding failure, failure to meet standard requirements, etc., to improve mechanical properties and stability, The effect of reducing production costs and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0023] Example.

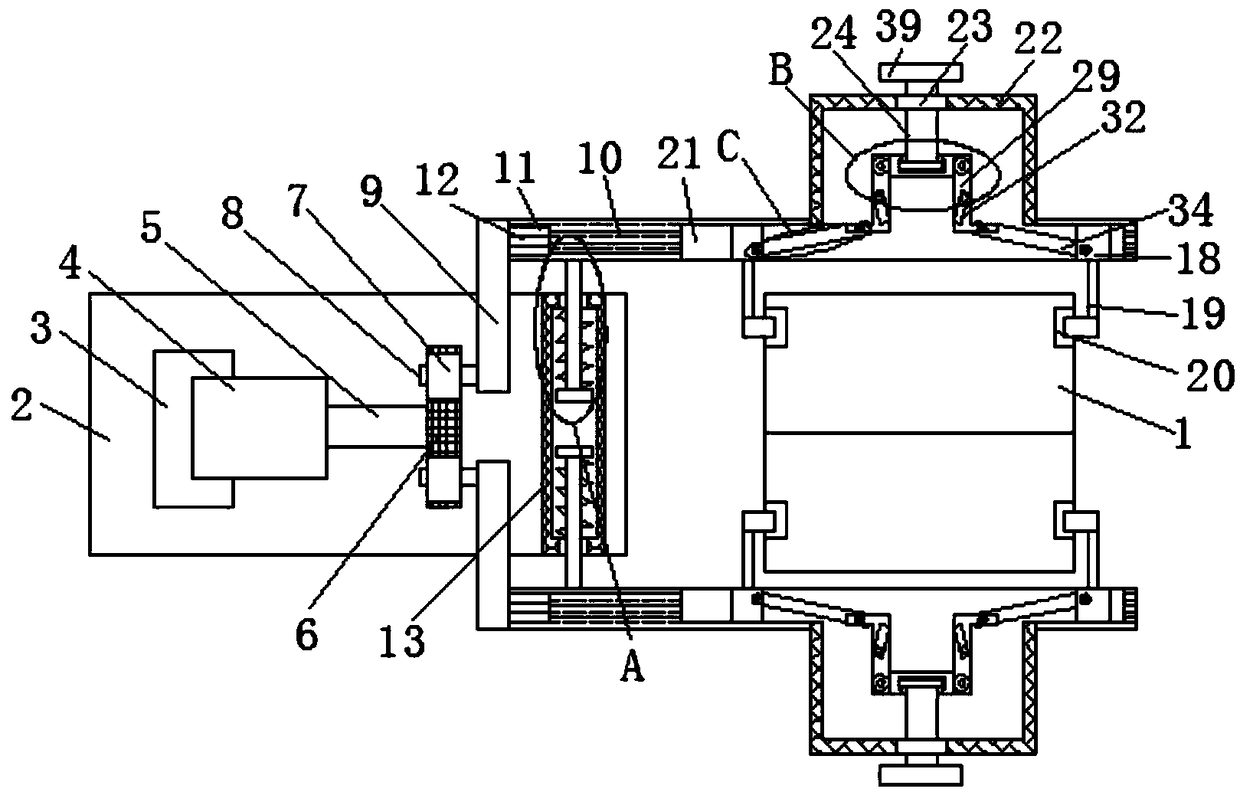

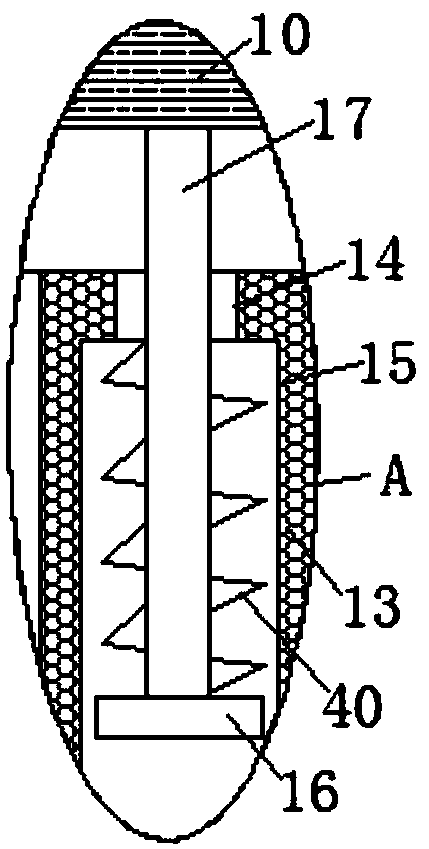

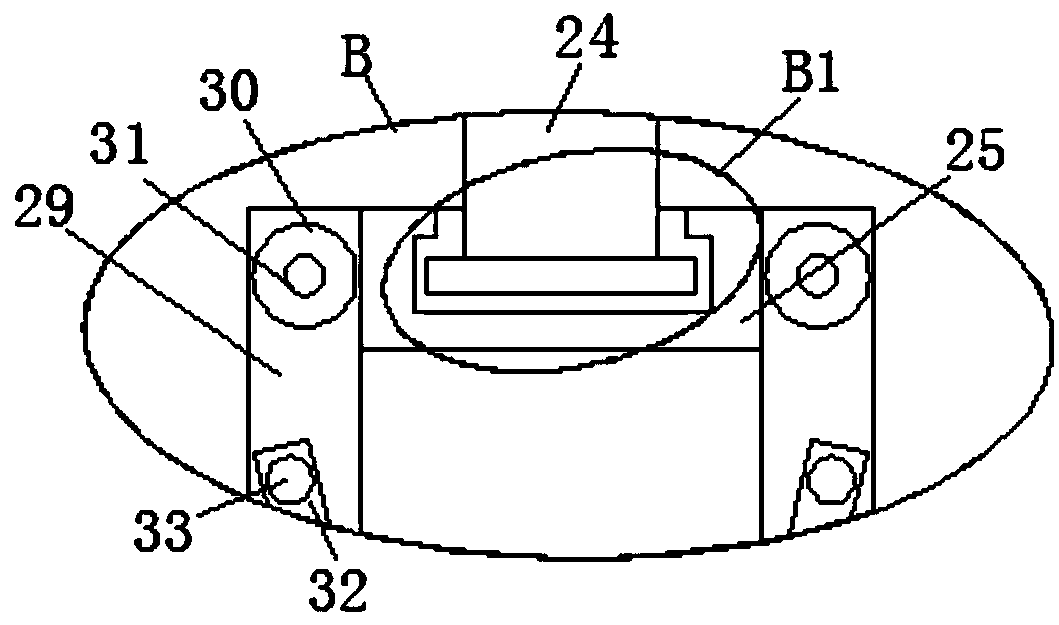

[0024] refer to Figure 1-5 , a kind of sand mold steel casting equipment, including two closely fitting molds 1, molten steel is cast in the two molds 1, and nitrogen element is added to the molten steel on the basis of the chemical composition of the original material, the addition amount is 0.1-0.3%, two The same side of the mold 1 is provided with a mounting plate 2, one side of the mounting plate 2 is fixedly installed with a mounting table 3, one side of the mounting table 3 is fixedly mounted with a motor 4, and the output shaft of the motor 4 is fixedly mounted with a rotating shaft 5 through a coupling One end of the rotating shaft 5 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com