A continuous dense wave forming method for bellows

A forming method and bellows technology, applied in storage devices, metal processing equipment, feeding devices, etc., can solve the problems of short dense wave tubes, inconvenient transportation, large dispersion of dense wave tubes, etc., and achieve good toughness and wear resistance. , convenient transportation, good molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings. For ease of description, the "left" and "right" mentioned below are consistent with the directions shown in the drawings.

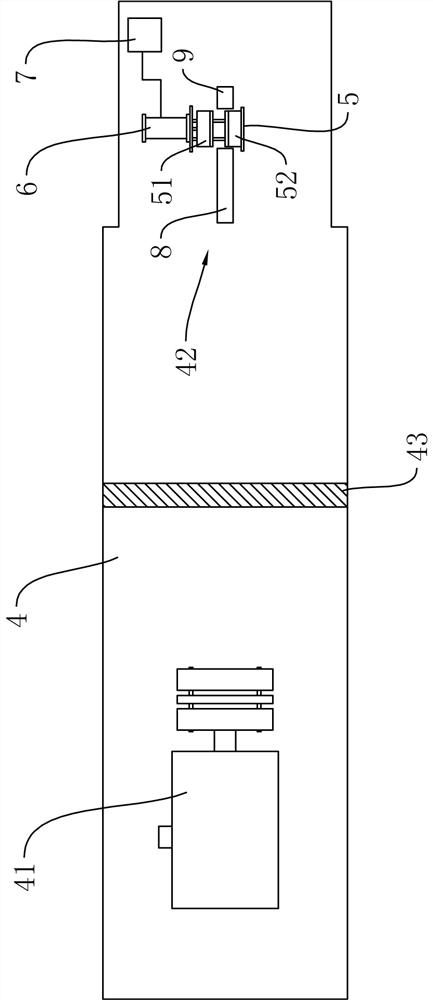

[0026] A continuous dense wave forming method for bellows, such as figure 1 As shown, it includes a stainless steel strip fixing machine 1, a welding table 2, a stainless steel pipe pulling machine 3, a workbench 4, and a dense wave tube automatic coiling machine 10 arranged in sequence from left to right. The workbench 4 is sequentially provided with corrugated Tube forming machine 41 and dense wave tube forming machine 42. In the process of forming dense wave tubes, the stainless steel strip is first placed on the stainless steel strip fixing machine 1, and the stainless steel strip is transported to the welding platform 2 under the traction of the stainless steel tube pulling machine 3, and the stainless steel strip is wound on the welding platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com