Particle shaping and regenerating machine

A particle and barrel technology, applied in the field of particle shaping and reprocessing machines, can solve the problems of difficult adjustment of the gap distance between the cutter head and the sieve cylinder, dust magazine entering the shaft seat, and wear of the shaft seat and the rotating shaft, etc., to meet the needs of particle shaping. , Easy assembly and disassembly, reliable connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

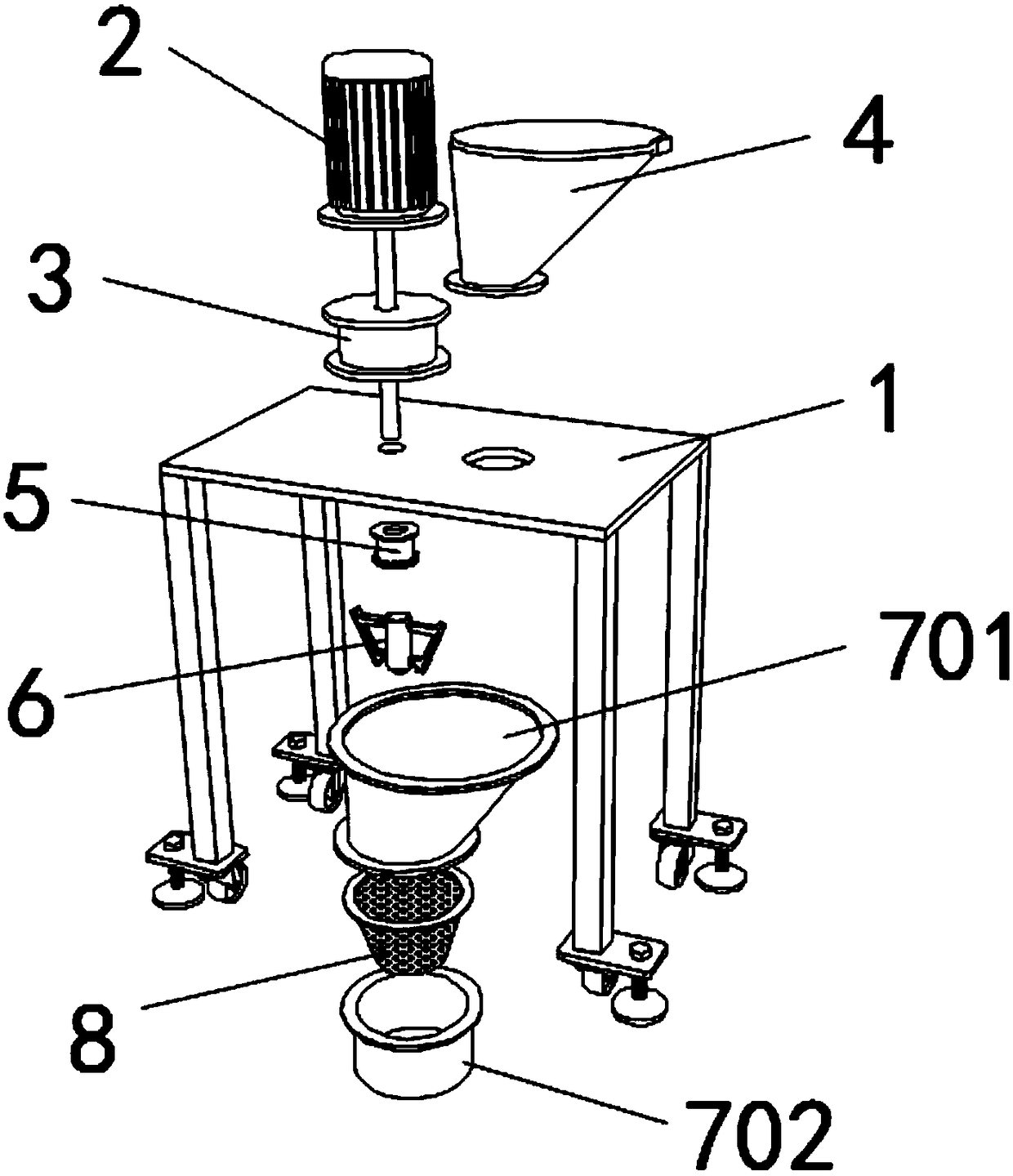

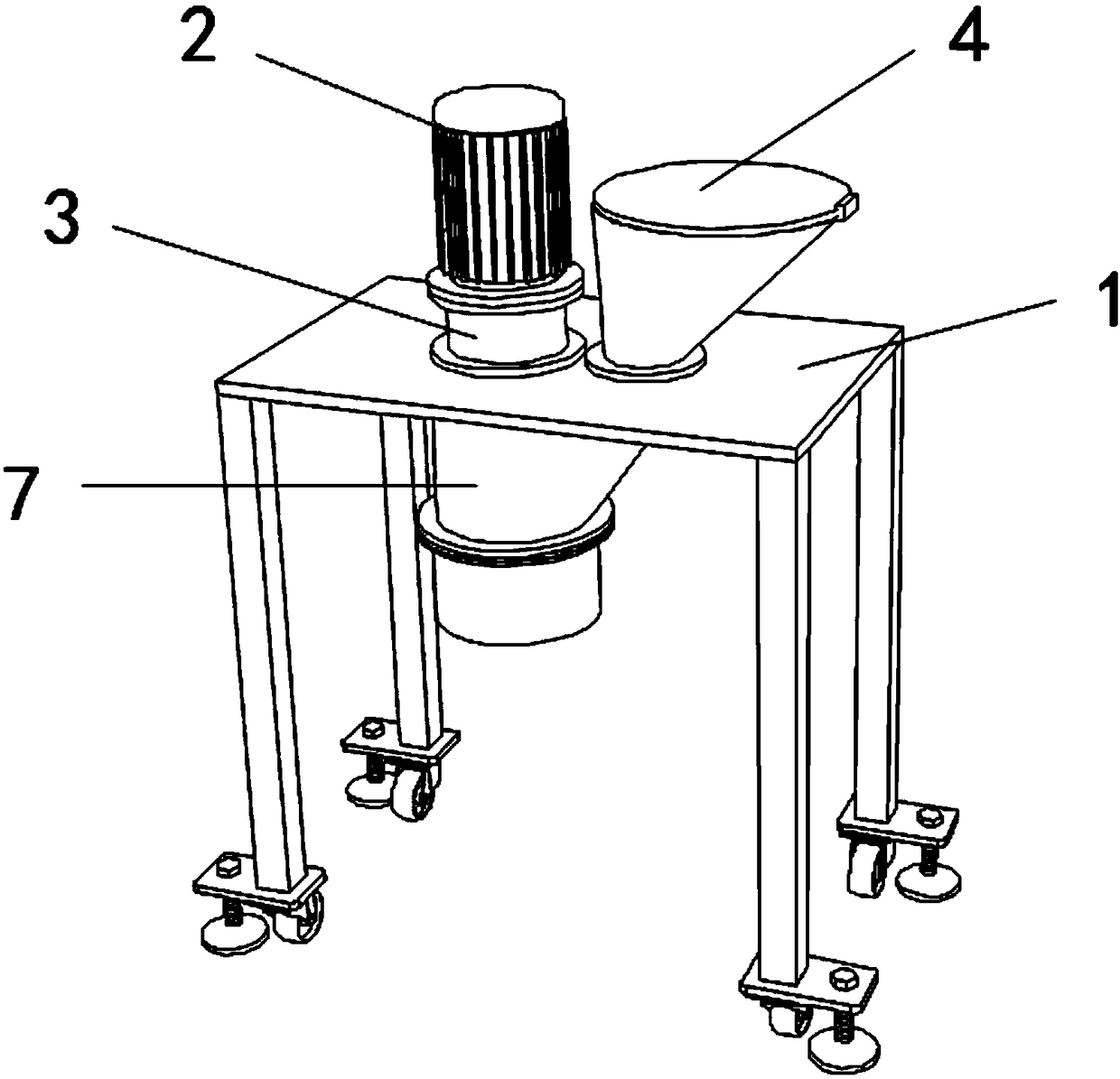

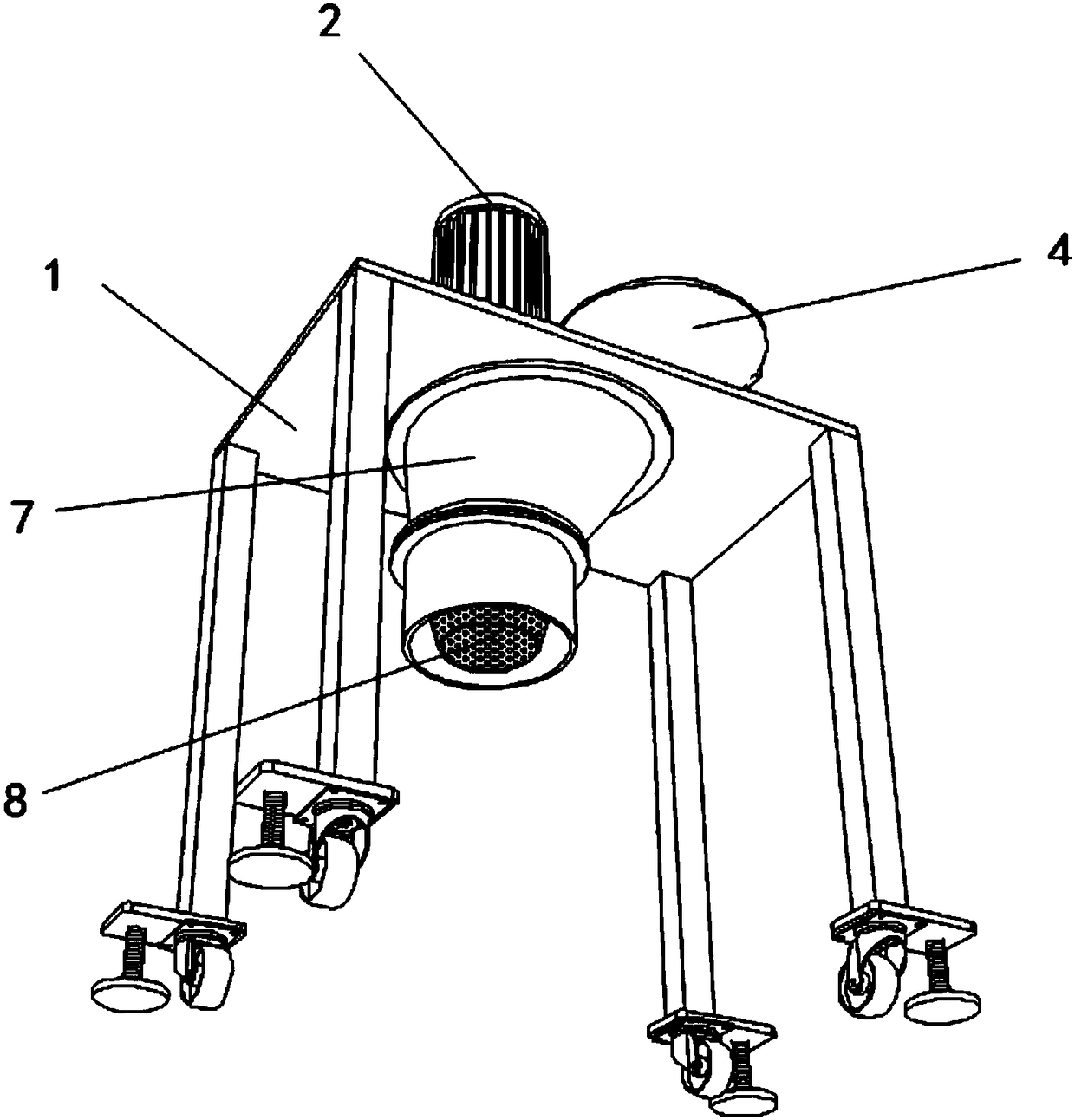

[0035] A particle shaping and recycling machine includes: frame body 1, transmission device 2, shaft seat 3, feed cylinder 4, shaft seal 5, cutter body 6, material cylinder 7, screen cylinder 8, bracket 101, mounting plate 102, rollers 103, foot support 104, motor 201, transmission shaft 202, copper sleeve 501, oil ring 502, packing packing 503, gland 504, tool holder 601, cutter head 602, connecting screw 603, first barrel 701, second Barrel 702; frame body 1 is made of support 101, mounting plate 102, roller 103 and foot support 104, and mounting plate 102 is provided with roller 103 and foot support 104; Axle base 3, and the upper and lower ends of the shaft base 3 are respectively connected with the bracket 101 and the motor 201 by screws; one end of the motor 201 is provided with a transmission shaft 202, and one end of the transmission shaft 202 runs through the shaft base 3, the bracket 101, the shaft The seal 5 is connected with the cutter body 6; one side of the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com