Scraper blade mechanism capable of feeding glue quantitatively

A quantitative gluing and scraper technology, applied in the field of composite machines, can solve the problems of uneven scraping, insufficient glue, scraper accumulation, etc., and achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

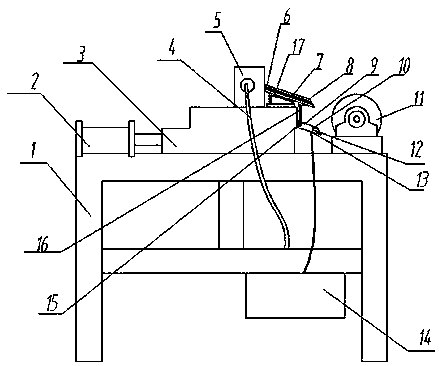

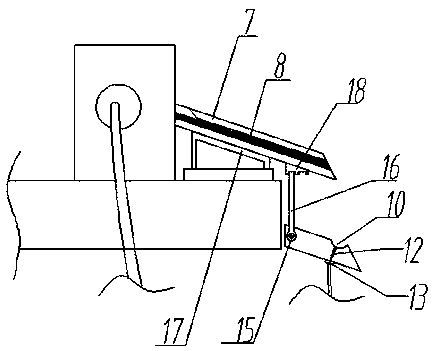

[0022] like figure 1 and figure 2 The shown scraper mechanism with quantitative gluing includes a moving seat 3 arranged on the frame 1, a tool mounting seat 17 arranged on the moving seat 3, and a glue output box is also arranged on the moving seat 3 5. An upper scraper 6 is arranged on the tool mounting seat 17 , the tail of the upper scraper 6 is connected with the head of the glue outlet box 5 , and the head of the upper scraper 6 extends out of the moving seat 3 . Described mobile base 3 is fixed on the described frame by guide rail, guide groove and cylinder 2, drives mobile base 3 to move on the frame by cylinder 2, can drive the movement of upper scraper 6 like this.

[0023] The glue outlet box 5 is connected with the glue trough 14 through a rubber hose and a pump, the glue trough 14 is a closed box, and is provided with an insulation layer and a heating mechanism, the glue outlet box 5 is provided with a glue hose, and There is a flow meter, and the glue outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com