Phosphorus-based negative electrode material and preparation method thereof, negative electrode and lithium ion battery

A phosphorus-based negative electrode and negative electrode technology, applied in the direction of negative electrodes, battery electrodes, secondary batteries, etc., can solve the problems of large volume expansion, poor conductivity of red phosphorus, etc., and achieve low cost, uniform and stable material properties, and coating uniformity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

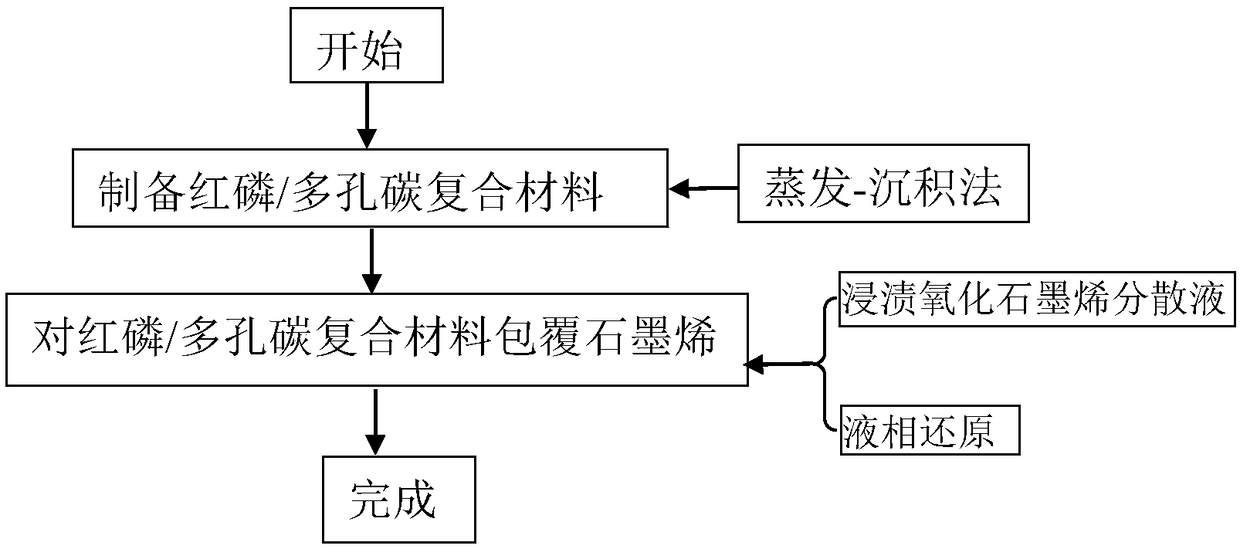

[0047] combine figure 2Shown is the flow chart of the preparation method of phosphorus / porous carbon@graphene composite material of the present invention. The preparation method basically includes two steps: S1, preparing phosphorus / porous carbon composite material; S2, coating graphene on the outside of the phosphorus / porous carbon composite material. Among them, the specific preparation method of phosphorus / porous carbon composite material in S1 can adopt the method of solid-solid intermixing of phosphorus-carbon powder, and can also adopt the method of evaporation-deposition. Preferably, the present invention adopts an evaporation-deposition method to prepare the phosphorus / porous carbon composite material. In the method of coating graphene in S2, the phosphorus / porous carbon composite powder can be directly put into the graphene dispersion for coating, or the phosphorus / porous carbon composite can be added to the graphene oxide dispersion , and then in the presence of a...

Embodiment 1

[0059] In this embodiment, the specific surface area is about 1300m 2 / g, the pore volume is about 0.8cm 3 / g of activated carbon to prepare red phosphorus / activated carbon@graphene composite material, the preparation process is as follows:

[0060] ①Take 20g of commercial micron red phosphorus powder (about 20μm) and wash it repeatedly with deionized water to remove surface oxides, and dry it in vacuum for later use;

[0061] ② Place the dried micron red phosphorus powder in a ball mill jar at 500 rpm, and ball mill it in an inert atmosphere for 20 hours to obtain nanometer red phosphorus (about 700nm);

[0062] ③Mix the nano-red phosphorus and activated carbon in a sealed ceramic boat according to the mass ratio of 1:1, and then transfer it to a sealed quartz tube. In an inert atmosphere, first heat to 450°C and keep it for 2 hours to sublimate the red phosphorus, and then naturally cool down to Keep the temperature at around 275°C for 48 hours to completely convert white ...

Embodiment 2

[0070] The difference between this embodiment and Example 1 is only that in step 5, the addition amount of graphene oxide is 0.3g, that is, 9.7g phosphorus / porous carbon composite material is added in the dispersed graphene oxide aqueous solution (0.3g graphite oxide Alkene + 50ml). Refer to Example 1 for other operations and test methods.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com