Preparation method for high-conductivity insulating composite material

An insulating composite material and high thermal conductivity technology, applied in the field of electronic materials, can solve the problems of product performance limitation, limited application scope, low thermal conductivity, etc., and achieve the effect of solving the matching problem of thermal conductivity and insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

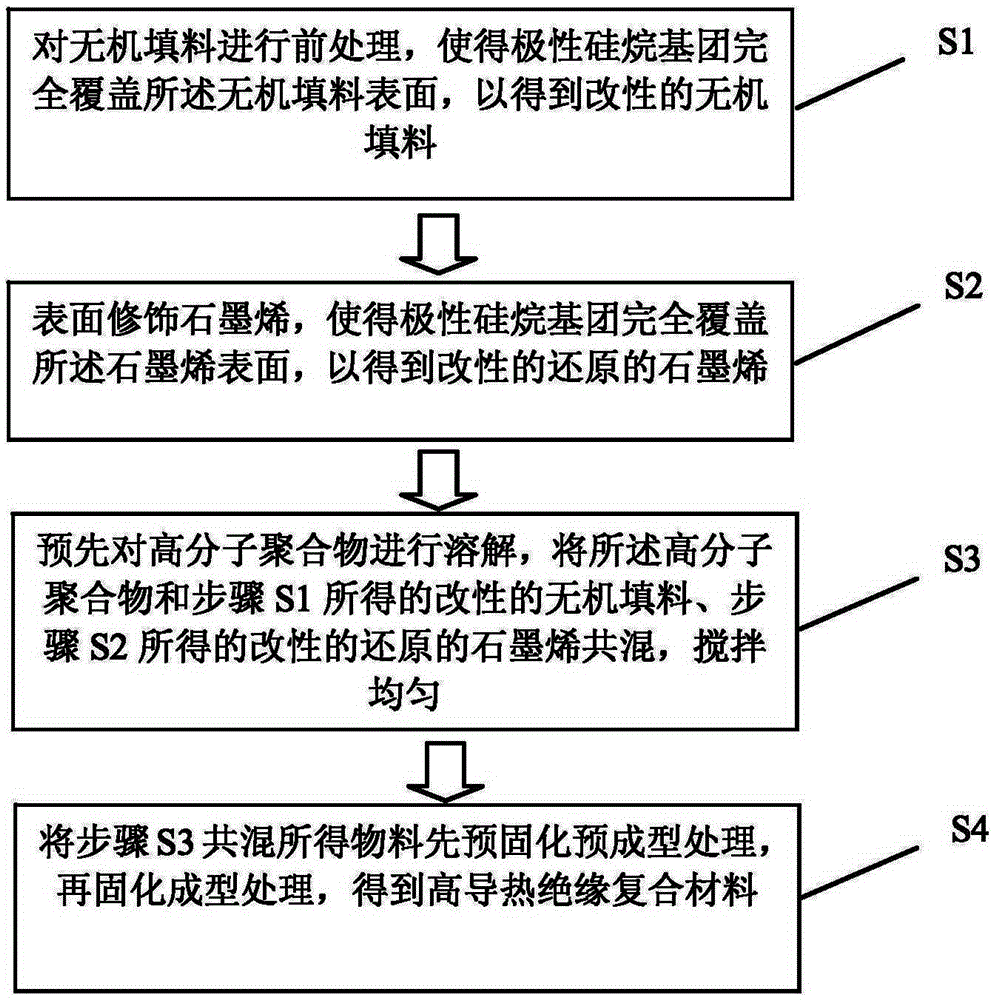

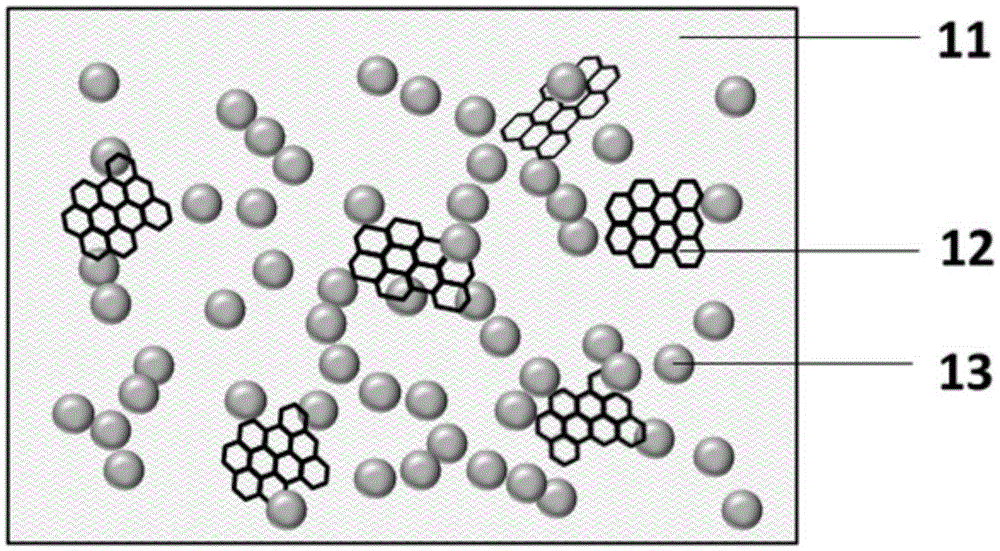

[0041] In order to solve the problems of the prior art, the present invention provides a method for preparing a high thermal conductivity insulating composite material, specifically, as figure 1 , figure 2 As shown, the preparation method roughly includes the following steps:

[0042] S1. Pre-treating the inorganic filler so that the polar silane group completely covers the surface of the inorganic filler to obtain a modified inorganic filler 13;

[0043] S2, modifying the surface of the graphene so that the polar silane group completely covers the surface of the graphene to obtain modified reduced graphene 12;

[0044] S3, dissolving the high molecular polymer 11 in advance, blending the high molecular polymer 11 with the modified inorganic filler 13 obtained in step S1, and the modified reduced graphene 12 obtained in step S2, and stirring evenly;

[0045] S4. Pre-cure and pre-form the material obtained by blending in step S3, and then perform curing and molding to obtain...

Embodiment 1

[0069] In this embodiment, aluminum nitride is selected as the inorganic filler, polyimide is selected as the polymer, and the high thermal conductivity insulating composite material is prepared according to the following steps:

[0070] S1. Pretreatment of aluminum nitride

[0071] (1) Weigh 10g of aluminum nitride powder, mix it with 100mL of absolute ethanol, and ultrasonically stir for 30min at 30-60°C to obtain an aluminum nitride suspension;

[0072] (2) Stir the aluminum nitride suspension at a temperature of 40-60 °C, add 0.15 g of silane coupling agent at the same time, continue stirring for 2-3 hours, take out the suspension, and use filtration or high-speed centrifugation for solid-liquid separation. After the obtained solid product is washed and dried, a modified aluminum nitride powder is obtained.

[0073] S2, carry out surface modification to graphene

[0074] (1) Weigh 1g of nano-graphene oxide (GO), dissolve it in 1L of deionized water, and stir it ultrasoni...

Embodiment 2

[0080] In this embodiment, aluminum nitride is still selected as the inorganic filler, but the composition of epoxy resin and curing agent is selected as the high molecular polymer, and the high thermal conductivity insulating composite material is prepared according to the following steps:

[0081] Step S1, step S2 are exactly the same as Embodiment 1, and will not be repeated;

[0082] S3. Weigh 2.6g epoxy resin and 2.5g curing agent, and use ethyl acetate to dissolve the epoxy resin and curing agent respectively, and dissolve the modified aluminum nitride powder obtained in step S1 in the epoxy resin In the solution, ultrasonically stir at a rate of 2000 rpm for 30 min at 30-60 °C, add the modified RGO obtained in step S2, continue to stir at a rate of 2000 rpm for 30 min, then add a curing agent, and then Min speed stirring 10 ~ 30min.

[0083]S4. Dry the material obtained in step S3 in an oven at 100° C. for 3 to 30 minutes for pre-curing and preforming treatment, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com