Sulfur element analysis auxiliary treatment device and method for eliminating influence of high content nitrogen element

An auxiliary treatment, sulfur element technology, applied in the direction of measuring device, analytical material, material excitation analysis, etc., can solve the problems of unable to obtain measurement results, affecting sulfur element analysis, high measurement value, etc., to achieve good compatibility and clear pipeline , the effect of eliminating the influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

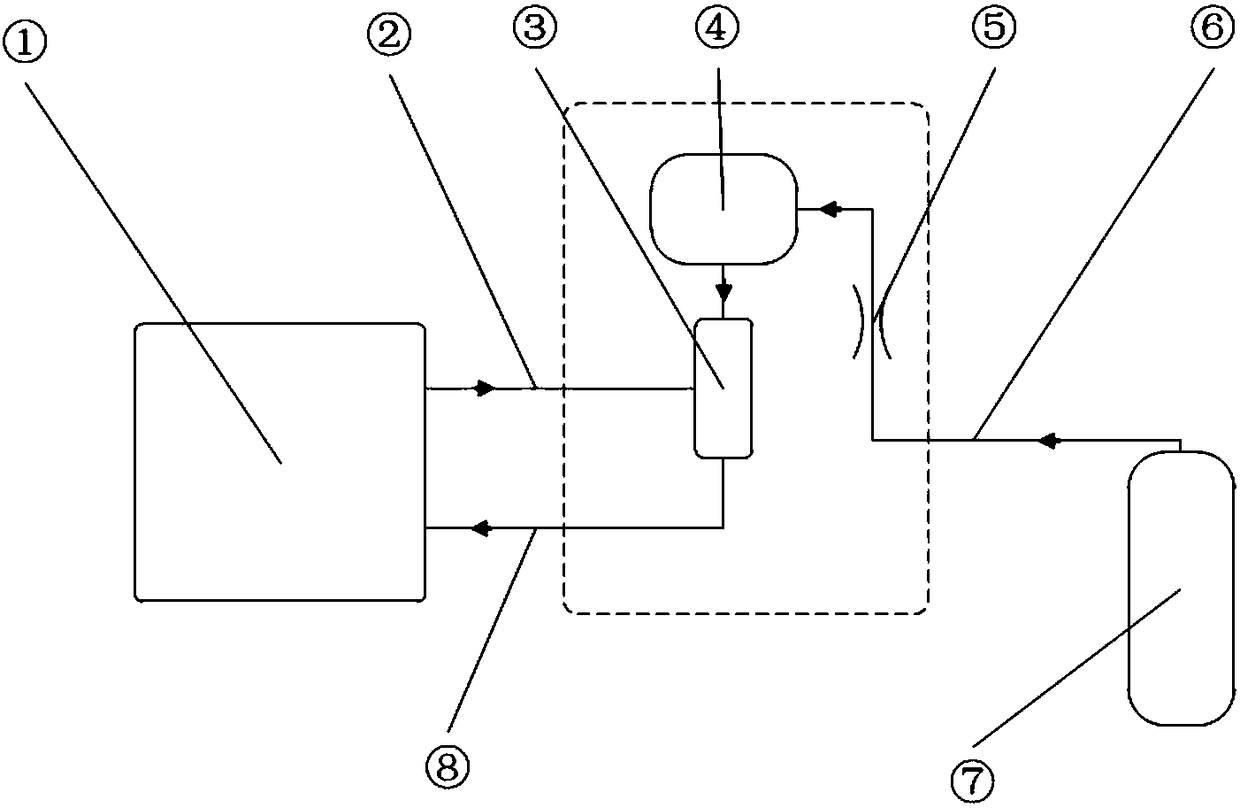

[0020] Such as figure 1 As shown, the present invention provides a kind of auxiliary treatment device for sulfur element analysis that eliminates the influence of high-content nitrogen element, which includes:

[0021] Oxygen inlet pipeline 6 is used to supply oxygen; in the present embodiment, oxygen cylinder 7 is used to supply oxygen;

[0022] A restrictor tube 5, one end of which is connected to the oxygen inlet pipeline 6;

[0023] Ozone generator 4, its inlet links to each other with the other end of described restrictor pipe 5, is used for converting oxygen into ozone;

[0024] Three-way reaction tube 3, its first inlet is connected with the outlet of described ozone generator 4, the second inlet is connected with sample gas inlet pipeline 2, and the outlet of three-way reaction tube 3 is then connected with sample gas outlet pipeline 8;

[0025] Wherein, the sample gas inlet pipeline 2 is used to connect the sample gas after high-temperature catalytic oxidation; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com