A construction method of quasi-conical energy-gathering cut

A construction method and quasi-conical technology, which is applied in the direction of earthwork drilling, mining equipment, tunnels, etc., can solve the problems of low blasthole utilization rate, unfavorable construction, cumbersome operation, etc., and achieve high blasthole utilization rate, high cutting efficiency, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

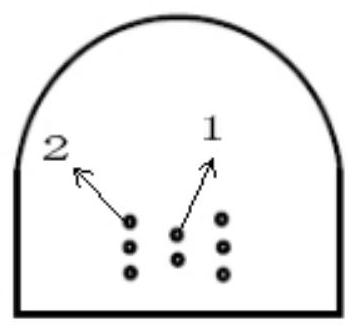

[0043] like Figure 2-4 As shown, there is one central hole, and the central hole is located directly below the intersection of the centerline of the roadway and the arch line, and the cut holes are arranged symmetrically along the center of the central hole. Preferably, the diameter of the central hole is larger than 100mm. When adopting large-diameter empty hole, can not charge medicine. The center hole is drilled with a special drilling rig, and the depth of one drilling can be used for 5-6 cycles.

Embodiment 2

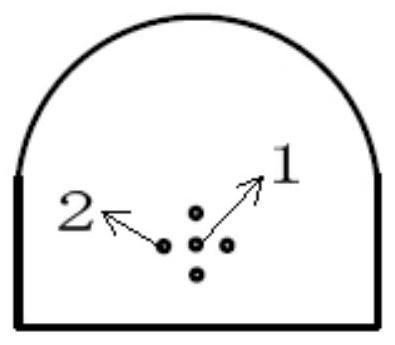

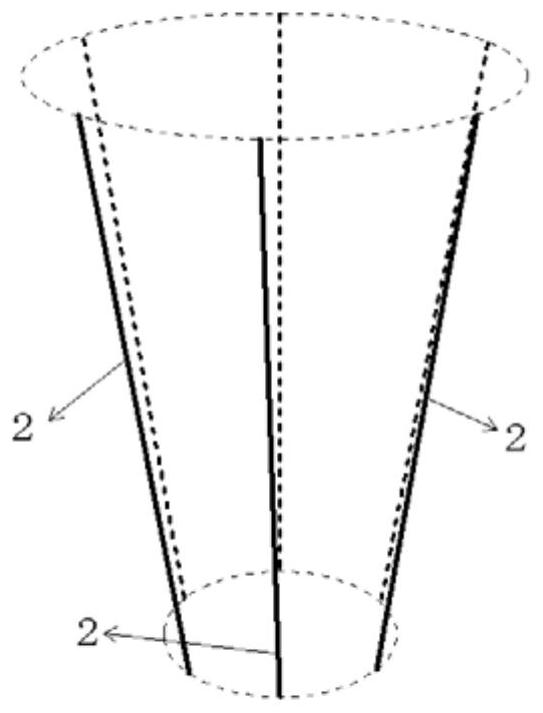

[0045] like Figure 5-7 As shown, the difference from Embodiment 1 is that there are multiple central holes in this embodiment, and the center of the shape surrounded by the central hole is located directly below the intersection of the centerline of the roadway and the arch line, and the cutout The holes are arranged centrally symmetrically along the center of the shape surrounded by the central hole. Preferably, four central holes are provided, and the central holes are surrounded by a rhombus or a rectangle, and two of the central holes are located directly below the intersection of the central line of the roadway and the arch line. Specifically, the four central holes in this embodiment are all arranged perpendicular to the working surface, and the central holes can also be arranged in different shapes according to actual needs.

[0046] The invention provides a quasi-conical energy-gathering cutting construction method. A central hole and multiple groups of cutting holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com