Rayon fiber

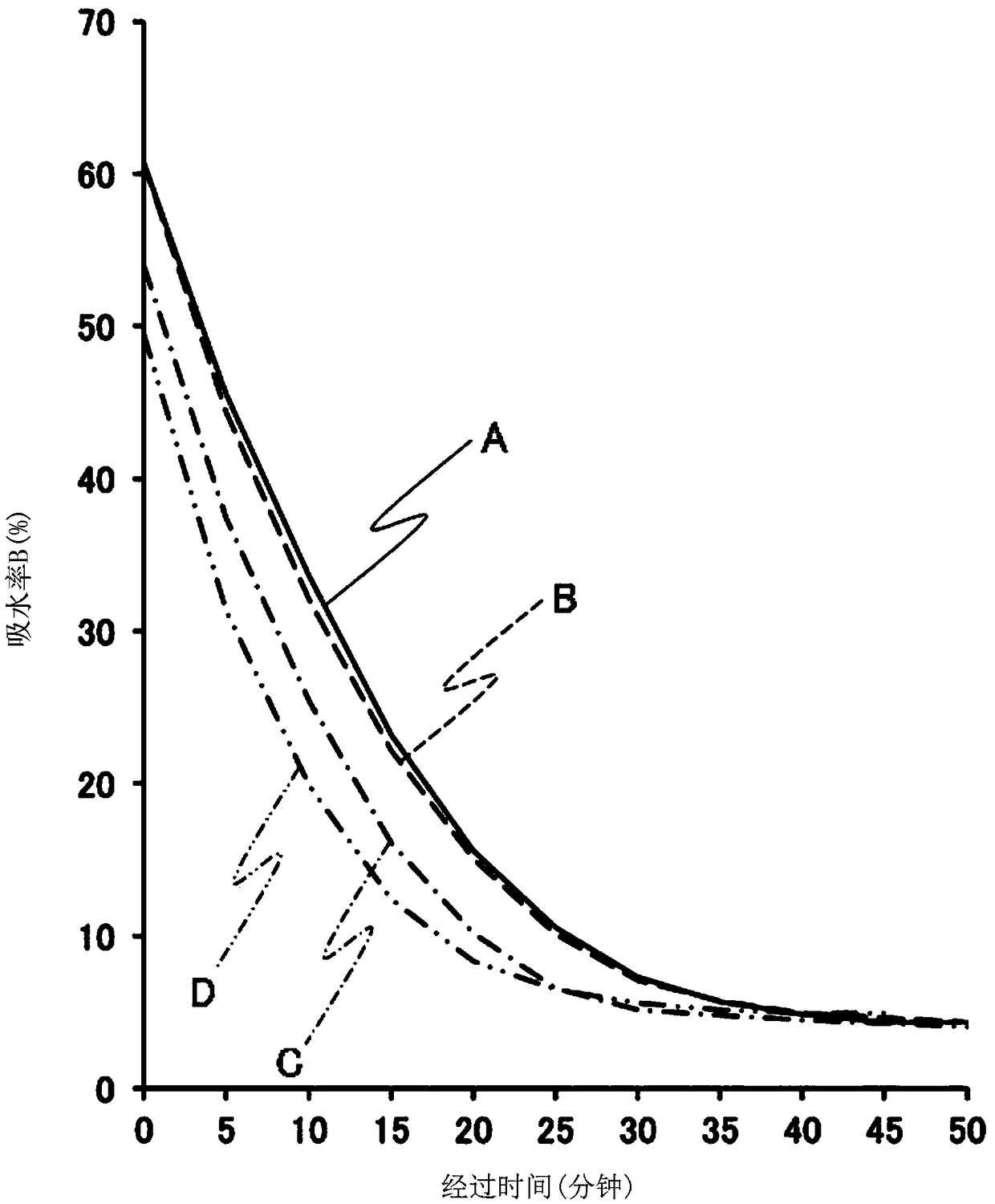

A rayon fiber and rayon technology, applied in the field of rayon fiber, can solve the problems of being unsuitable for underwear, and the coloring of moisturizing rayon fiber becomes darker, and achieve excellent water absorption and quick-drying effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0067] Alkali cellulose was obtained by immersing the raw material pulp in an aqueous solution of about 18% by mass of sodium hydroxide, pressing, and pulverizing. The alkali cellulose obtained above was left to stand at a temperature of 40 to 60° C. for about 6 hours, and then carbon disulfide was blown over the alkali cellulose to react the alkali cellulose with carbon disulfide to obtain xanthate. Viscose fibers were prepared by dissolving the xanthate obtained above in dilute aqueous sodium hydroxide solution.

[0068] The cellulose content in the viscose fiber obtained above was 9% by mass, the alkali content in the viscose fiber was 5% by mass, and the falling ball viscosity at 25° C. of the viscose fiber was 50 seconds. In addition, the falling ball viscosity is the value when it measured by the method described in JISZ8803.

preparation example 2

[0070] Wash with water after dissolving 1 kg of frozen Mizuzenji Spirulina. The above-mentioned Spirulina was added to 5 L of hydrochloric acid with a pH of 3.0, and heated at 60° C. for 1 hour with stirring. After taking it out from the hydrochloric acid, it was added to an aqueous solution of isopropanol containing 30% by volume of water, and heated at 60° C. Heating was carried out for about 12 hours while stirring at room temperature. Next, Spirulina Suizenji was separated from the aqueous solution of isopropanol, and dried by standing in the air at room temperature for about 12 hours to obtain about 12 g of dried Spirulina Suizenji.

[0071] About 12 g of the dried Spirulina Suizenji obtained above was added to 4 L (liters) of a 0.1N aqueous sodium hydroxide solution (the same applies hereinafter), and heated at 70° C. for 3 hours while stirring, thereby dissolving the dried Spirulina Suizenji in sodium hydroxide aqueous solution. The resulting solution was neutralized ...

Embodiment 1

[0074] The viscose fiber obtained above was mixed with the polysaccharide derived from Cyanobacteria Suizenji obtained above, and the polysaccharide derived from Cyanobacteria Suizenji was dissolved to have a uniform composition, thereby preparing a spinning dope, wherein, relative to The amount of the polysaccharide derived from Suizenji algae was 0.01 parts by mass per 100 parts by mass of the rayon contained in the viscose fiber.

[0075] For the spinning dope obtained above, the spinning nozzle with 13000 nozzles with a diameter of 0.06mm was immersed in a coagulation bath at 47°C (containing 95g / L of sulfuric acid, 350g / L of sodium sulfate and 12.5g / L of zinc sulfate). Sulfuric acid aqueous solution), extrude the spinning dope from the nozzle of the spinning nozzle with a spinning speed of 60m / min and make it coagulate, thereby perform spinning, and cut it after stretching, thus obtaining a fineness of 1.4dtex, Rayon fibers with a fiber length of 38 mm.

[0076] Next, ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com