A bovine bone collagen peptide and a preparation method thereof and use

A technology of bone collagen peptides and collagen peptides, applied in the fields of food engineering and biology, can solve the problems of insufficient extraction rate of bovine collagen peptides, insufficient small molecule active peptides, etc., and achieve the effect of small molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

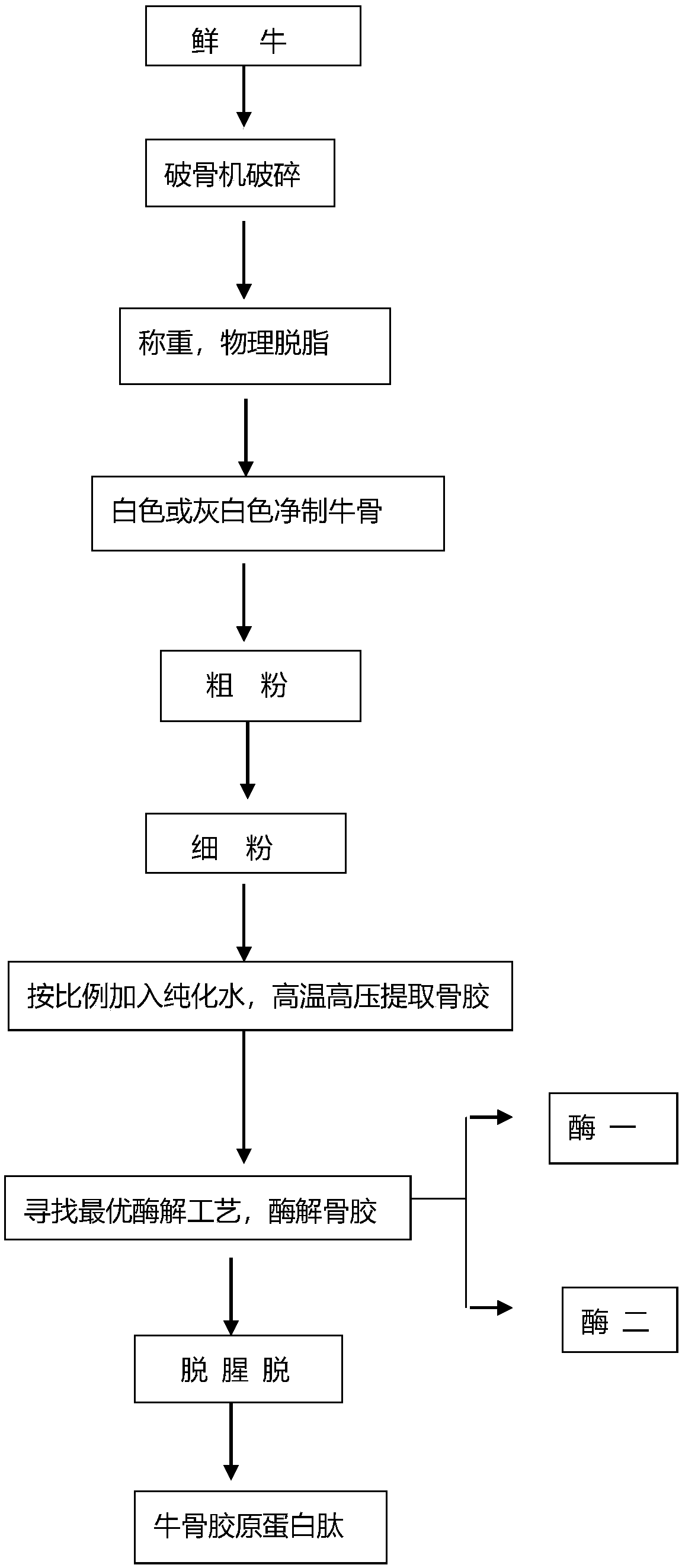

Method used

Image

Examples

Embodiment 1

[0039] Preparation:

[0040] (1) Take a certain amount of fresh beef bones that have passed inspection and quarantine, crush them, wash them, add an equal volume of water, and cook them for 0.5 hours.

[0041] (2) Discard the beef bone cooking liquid obtained in step (1), take out the beef bone, remove the meat, fascia, and fat in the bone cavity attached to the bone, and then wash it with hot water twice until the bone turns white Or milky white, no oil visible to the naked eye, to get clean beef bones.

[0042] (3), pulverize the bovine bone obtained in the step (2), and cross a 100-mesh standard sieve to obtain bovine bone fine powder.

[0043] (4), adding 5 times the quality of water to the bovine bone fine powder obtained in step (3), high temperature and high pressure for 40 minutes, filtering to get the supernatant to obtain bovine bone collagen liquid.

[0044] (5) Add 2% trypsin to the bovine bone collagen solution obtained in step (4), adjust the pH value to 8.0, a...

Embodiment 2

[0050] Preparation:

[0051] (1) Take a certain amount of fresh beef bones that have passed inspection and quarantine, crush them, wash them, add an equal volume of water, and cook for 1 hour.

[0052] (2) Discard the beef bone cooking solution obtained in step (1), take out the beef bone, remove the meat, fascia, and grease in the bone cavity attached to the bone, and then wash with hot water for 3 times until the bone turns white Or milky white, no oil visible to the naked eye, to get clean beef bones.

[0053] (3), pulverize the bovine bone obtained in the step (2), and cross a 100-mesh standard sieve to obtain bovine bone fine powder.

[0054] (4), add the bovine bone fine powder that obtains in step (3), add the water of 6 times of quality, high temperature and high pressure 40min, filter and take supernatant, obtain bovine bone collagen protein liquid.

[0055] (5) Add 0.5% trypsin to the bovine bone collagen solution obtained in step (4), adjust the pH value to 7.0, a...

Embodiment 3

[0059] Preparation:

[0060] (1) Take a certain amount of fresh beef bones that have passed inspection and quarantine, crush them, wash them, add an equal volume of water, and cook for 1.5 hours.

[0061] (2) Discard the beef bone cooking solution obtained in step (1), take out the beef bone, remove the meat, fascia, and grease in the bone cavity attached to the bone, and then wash with hot water for 3 times until the bone turns white Or milky white, no oil visible to the naked eye, to get clean beef bones.

[0062] (3), pulverize the bovine bone obtained in the step (2), and cross a 100-mesh standard sieve to obtain bovine bone fine powder.

[0063] (4) Add 10 times the mass of water to the fine bovine bone powder obtained in step (3), subject it to high temperature and high pressure for 2 hours, filter to get the supernatant, and obtain a bovine bone collagen liquid.

[0064] (5) Add 1.5% trypsin to the bovine bone collagen solution obtained in step (4), adjust the pH valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com