Rare earth element modified hydroisomerization catalyst, synthesis method and application thereof

A rare earth element, hydrogenation isomerization technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve problems such as no relevant reports, achieve wide application prospects, high-efficiency utilization, and simple and easy-to-operate methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

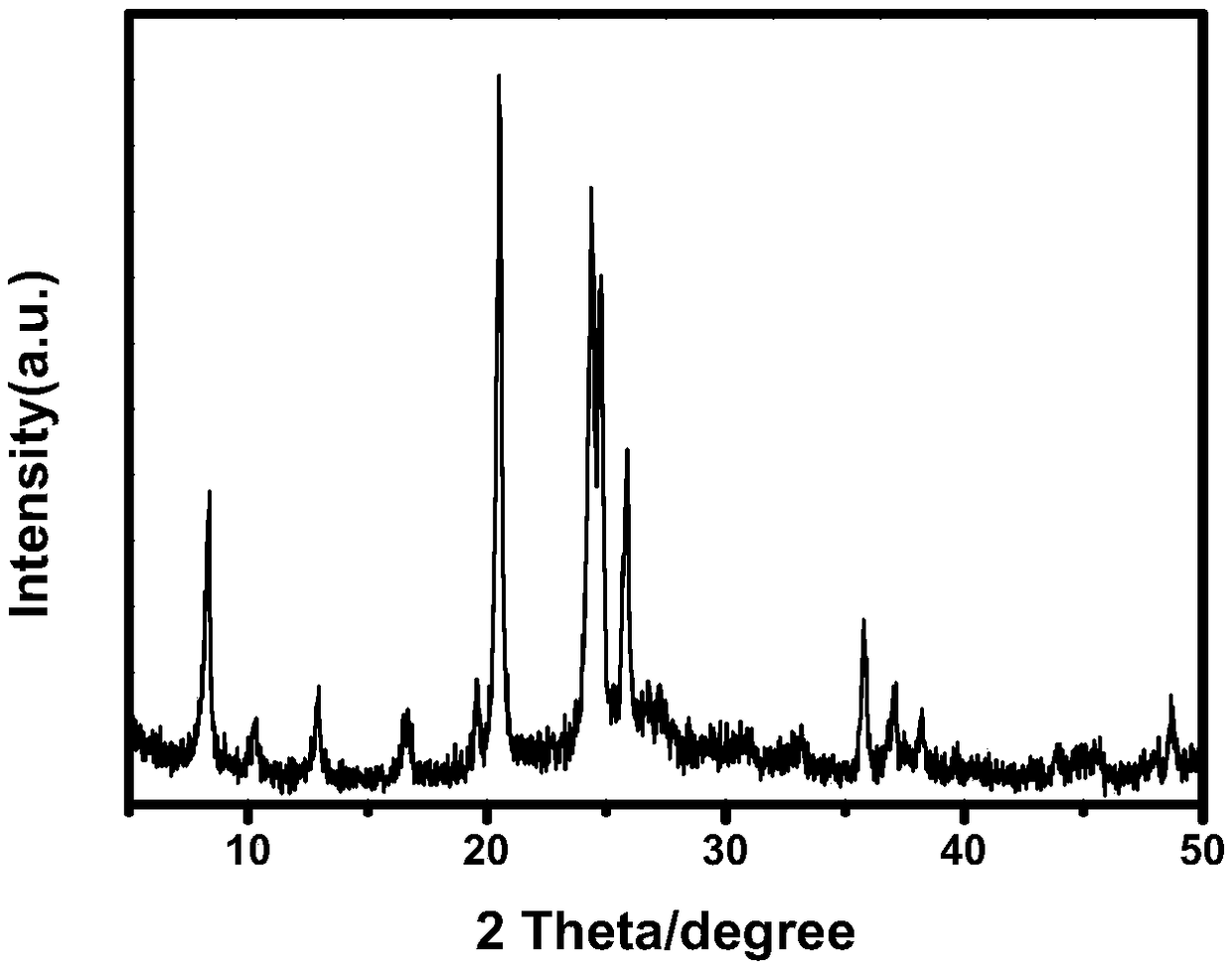

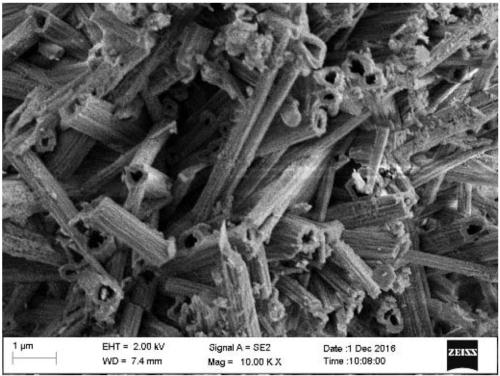

[0063] This embodiment provides a method for synthesizing a rare earth element-modified hydroisomerization catalyst, such as Figure 16 shown, including the following steps:

[0064] Weigh 3.90g KOH and dissolve in 10mL distilled water to make solution A, under vigorous stirring, prepare 1.45g Al 2 (SO 4 ) 3 18H 2 30mL solution B of O (aluminum sulfate) was slowly added to solution A to obtain mixed solution C, and then 8.35g of 1,6-hexamethylenediamine was weighed and dissolved in 10mL deionized water and slowly added to the above mixed solution C, Obtain a clear D solution; weigh 50.00g TEOS and 1.10g La(NO 3 ) 3 ·6H 2 Dissolve O (lanthanum nitrate) in 50mL 0.1M HCl, stir at 60°C for 240min to obtain colloid E; pour D into E, and continue stirring for 60min to obtain a white gel; transfer the gel to a liner containing PTFE In a high-pressure reaction kettle, heat up at 20°C for 400min in a rotary oven and keep at 200°C for 2h. The product is washed until neutral, and ...

Embodiment 2

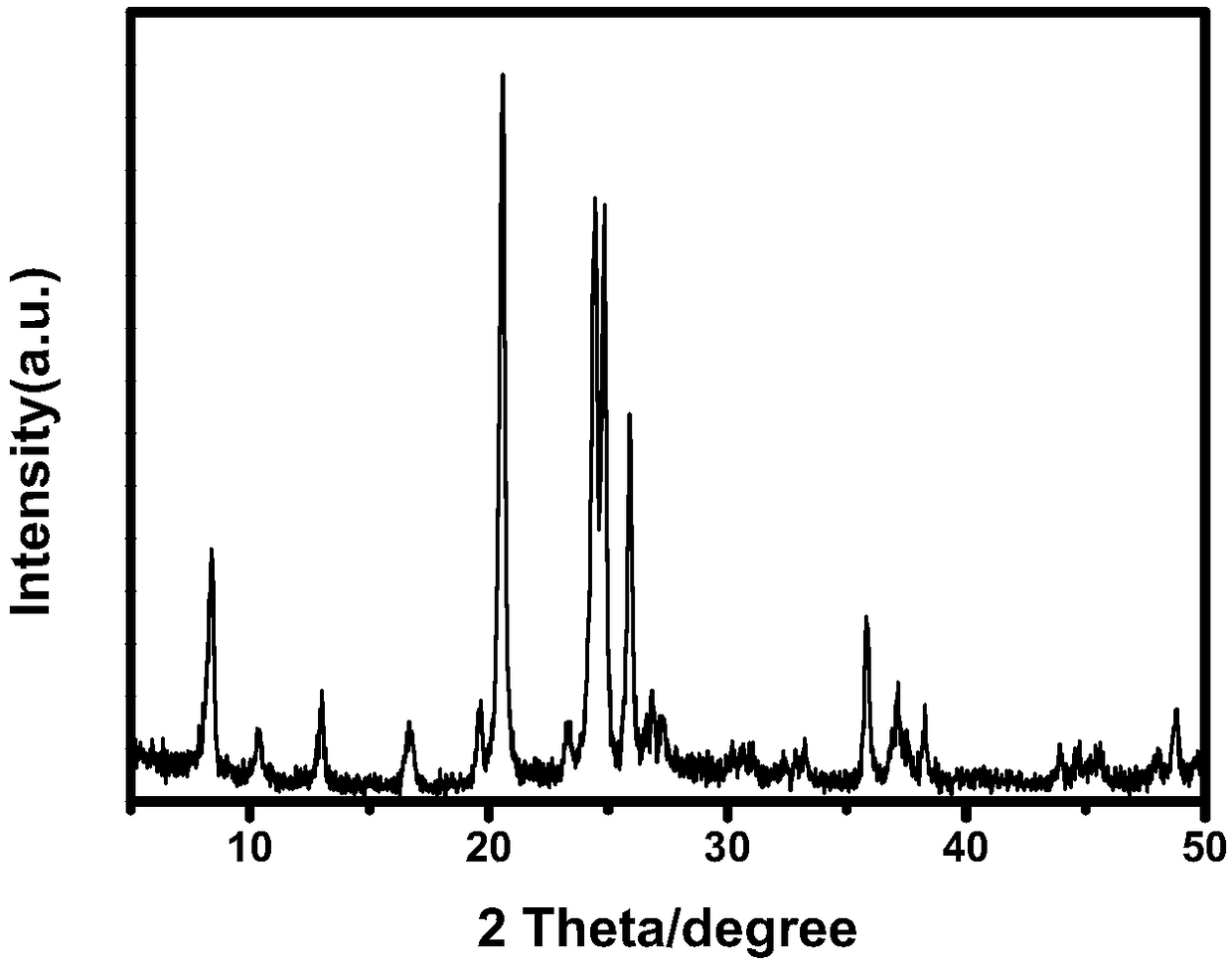

[0068] This embodiment provides a method for synthesizing a rare earth element-modified hydroisomerization catalyst, comprising the following steps:

[0069]Weigh 24g NaOH and dissolve in 200mL distilled water to make solution A. Under vigorous stirring, prepare 433mL solution B containing 33g sodium aluminate, slowly add to solution A to obtain mixed solution C, then weigh 30g ethylenediamine and dissolve in Slowly add 300mL of deionized water into the above mixed solution C to obtain a clear D solution; weigh 37.50g of silica sol (40wt%) and 45g of cerium nitrate and dissolve them in 375mL of 0.2M sulfuric acid, stir at 120°C for 240min to obtain colloid E ; Pour D into E, and continue to stir for 60 minutes to obtain a white gel; transfer the gel to a high-pressure reactor with a polytetrafluoroethylene liner, heat up at 20°C for 400min in a rotary oven, and keep at 120°C for 120h. The product was washed until neutral, and left in an oven at 90°C for 12 hours to obtain La-Z...

Embodiment 3

[0073] This embodiment provides a method for synthesizing a rare earth element-modified hydroisomerization catalyst, comprising the following steps:

[0074] Weigh 33.66g KOH dissolved in 100mL distilled water to make solution A, under vigorous stirring, prepare 300mL solution B containing 15.6g aluminum hydroxide, slowly add to solution A to obtain mixed solution C, then weigh 73.00g triethylene glycol Tetramine was dissolved in 500mL deionized water and slowly added to the above mixed solution C to obtain a clear solution D; weigh 37.50g of silica gel and 12.25g of La(NO 3 ) 3 ·6H 2 Dissolve O lanthanum chloride in 750mL 0.3M nitric acid, stir at 110°C for 120min to obtain colloid E; pour D into E, and continue to stir for 60min to obtain a white gel; transfer the gel to a polytetrafluoroethylene-lined In a high-pressure reaction kettle, heat up at 20°C for 400min in a rotary oven and keep at 150°C for 48h. The product is washed until neutral, and left in an oven at 100°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com