Dialyzer, dialysis apparatus, and method for manufacturing dialyzer

A manufacturing method and a technology of a dialysis device, which are applied in the direction of suction devices, drug devices, and other medical devices, can solve the problems that the effective membrane area of a dialyzer is difficult to increase, and achieve the effect of improving the removal performance and increasing the effective membrane area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

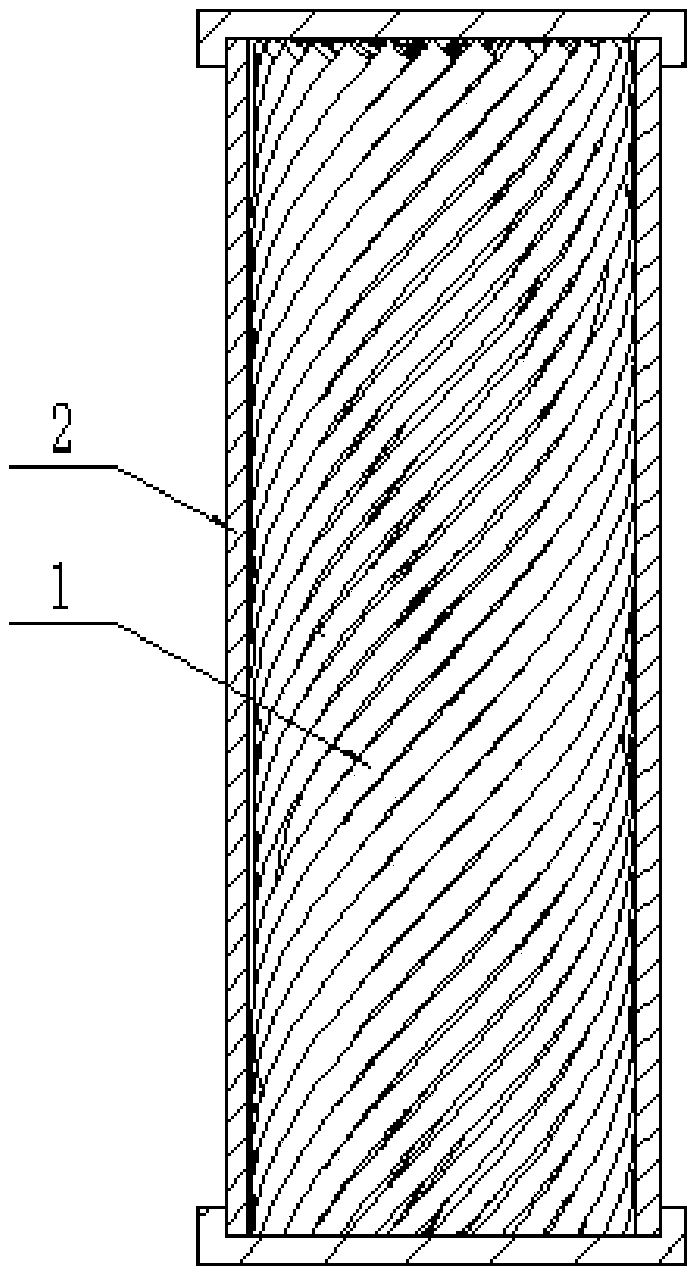

[0033] Such as figure 1 As shown, the dialyzer provided by the embodiment of the present invention includes: a filter medium 1 and a dialyzer housing 2. The filter medium 1 is arranged in the dialyzer housing 2 and extends along the axial direction of the dialyzer housing 2.

[0034] Specifically, the curved filter medium 1 is inserted into the dialyzer housing 2, so that the effective length of the filter medium 1 can be increased without increasing the volume of the dialyzer housing 2, thereby increasing the effective membrane area.

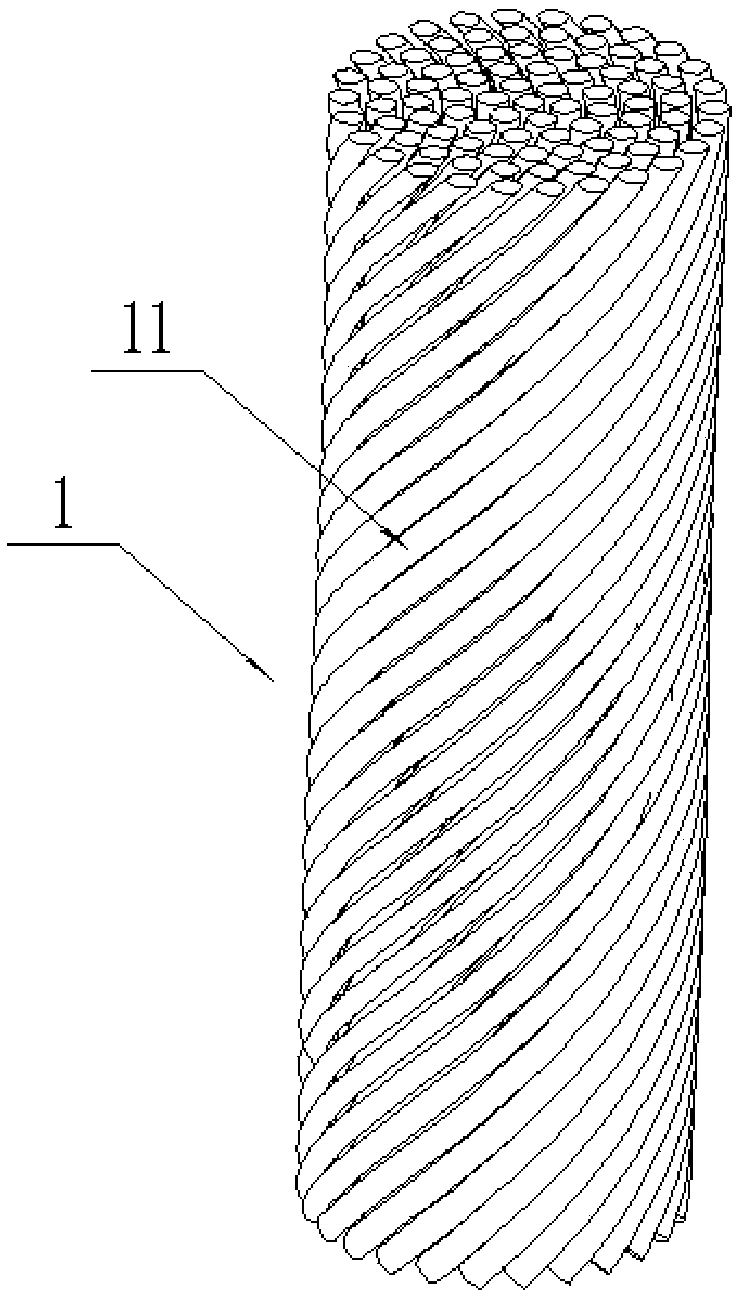

[0035] In the embodiment of the present invention, the filter medium 1 includes membrane filaments 11, and multiple membrane filaments 11 are spirally distributed along the axis of the dialyzer housing 2. Among them, the plurality of membrane filaments 11 are spirally distributed along the axis of the dialyzer housing 2, thereby ensuring that the plurality of membrane filaments 11 are closely attached, so that the number and length of the membrane fi...

Embodiment 2

[0061] Such as Figure 4 As shown, the dialysis device provided by the embodiment of the present invention includes: a dialysis machine 3, a peristaltic pump 4, a simulation fluid tank 5, and the dialyzer provided in Embodiment 1. The simulation fluid tank 5, the peristaltic pump 4, and the dialyzer are in fluid communication in sequence, The dialysis device is in fluid communication with the dialysis machine 3. Among them, the peristaltic pump 4 is used to suck out the simulated liquid from the simulated liquid tank 5, or to draw blood from the patient, and to introduce the simulated liquid or blood into the dialyzer; the dialysis machine 3 is used to introduce the dialysate into the dialyzer, and It is discharged after flowing through the dialyzer.

[0062] It should be noted that the dialyzer assembled with parallel membrane bundles and twisted membrane bundles is subjected to in vitro simulation experiments to simulate the dialysis process of patients with end-stage renal dis...

Embodiment 3

[0075] The manufacturing method of the dialyzer provided by the embodiment of the present invention includes the following steps: membrane bundle spinning: the two ends of the membrane bundle are respectively rotated around the axis of the membrane bundle in opposite directions; the membrane bundle loading: loading the rotated membrane bundle on the dialyzer housing 体2内。 In the body 2. Among them, by twisting the membrane bundle in the opposite direction, the effective length of the membrane filament 11 can be increased, thereby increasing the effective length of the membrane filament 11 in the dialyzer housing 2 of a certain volume.

[0076] Further, the angle at which one end of the membrane bundle rotates relative to the other end of the membrane bundle is greater than or equal to 360 degrees. Specifically, the membrane bundle is twisted at least once to obtain a larger effective length of the membrane filament 11.

[0077] Further, the manufacturing method of the dialyzer furthe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com