Composite filter element assembly and water purification system

A composite filter element and filter element technology, applied in chemical instruments and methods, osmotic/dialysis water/sewage treatment, semi-permeable membrane separation, etc. High filtration accuracy, low operating cost, and the effect of increasing the effective membrane area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

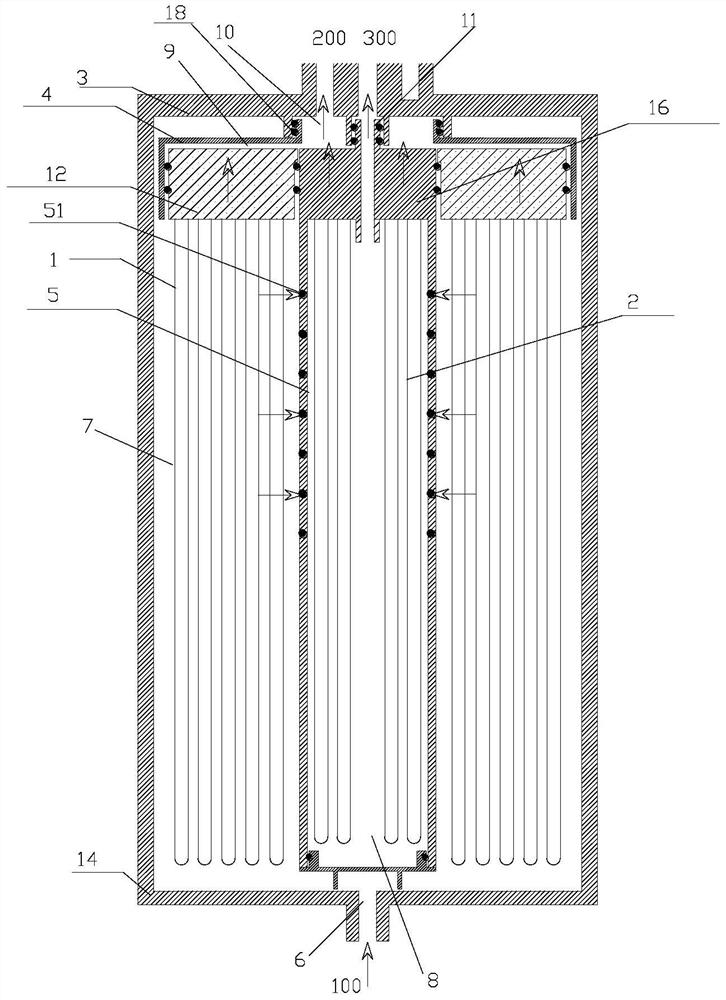

[0027] Such as figure 1 As shown, the present invention provides a composite filter element assembly, which includes:

[0028] Raw water inlet 100, produced water outlet 200, waste water outlet 300, a first filter element 1 and a second filter element 2, the first filter element 1 includes a first hollow fiber filter membrane filament, and the second filter element 2 includes a second hollow fiber filter element Membrane filaments, the second filter element 2 is located radially inside the first filter element 1, the water entering the raw water inlet 100 can be filtered through the first filter element 1, and enter the first hollow fiber when filtering Filter the inside of the membrane filament and finally lead out through the water production outlet 200, the water that does not enter the inside of the first filter element 1 can be filtered through the second filter element 2, and enter the second hollow fiber filter when filtering The interior of the membrane filament is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com