Ladder water inflowing rolling membrane element of opening water producing runner

A water production channel and roll membrane technology, which is applied in osmotic/dialysis water/sewage treatment, membrane technology, semi-permeable membrane separation, etc. The effect of increasing water production, improving recovery rate and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

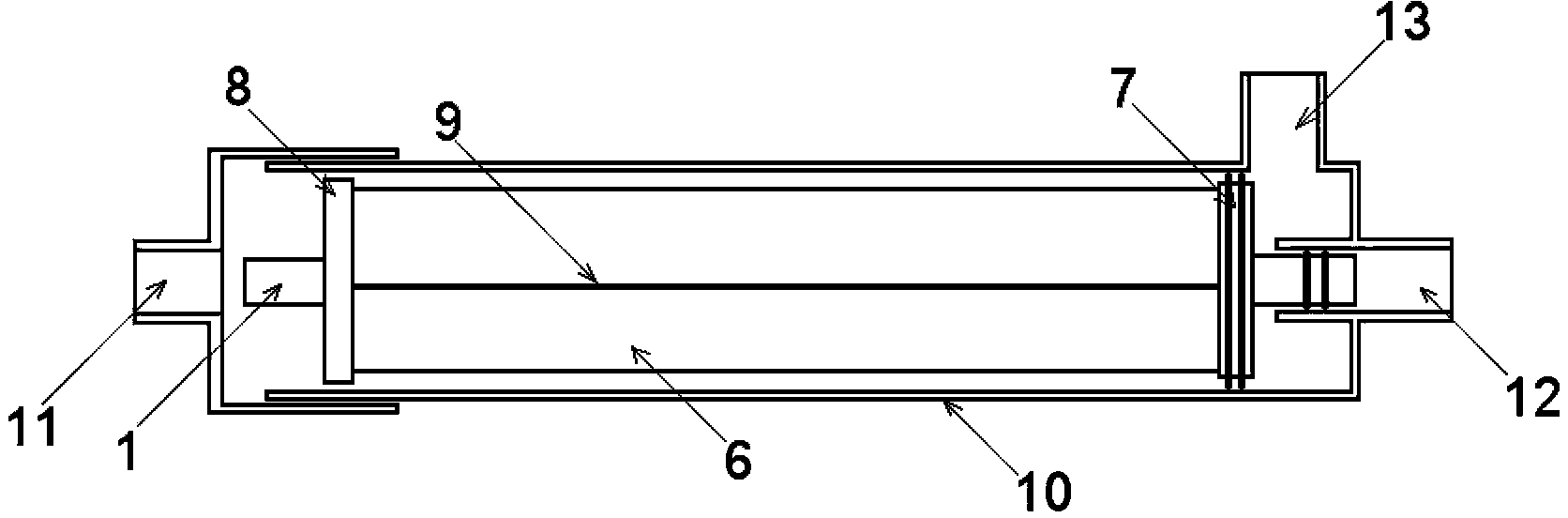

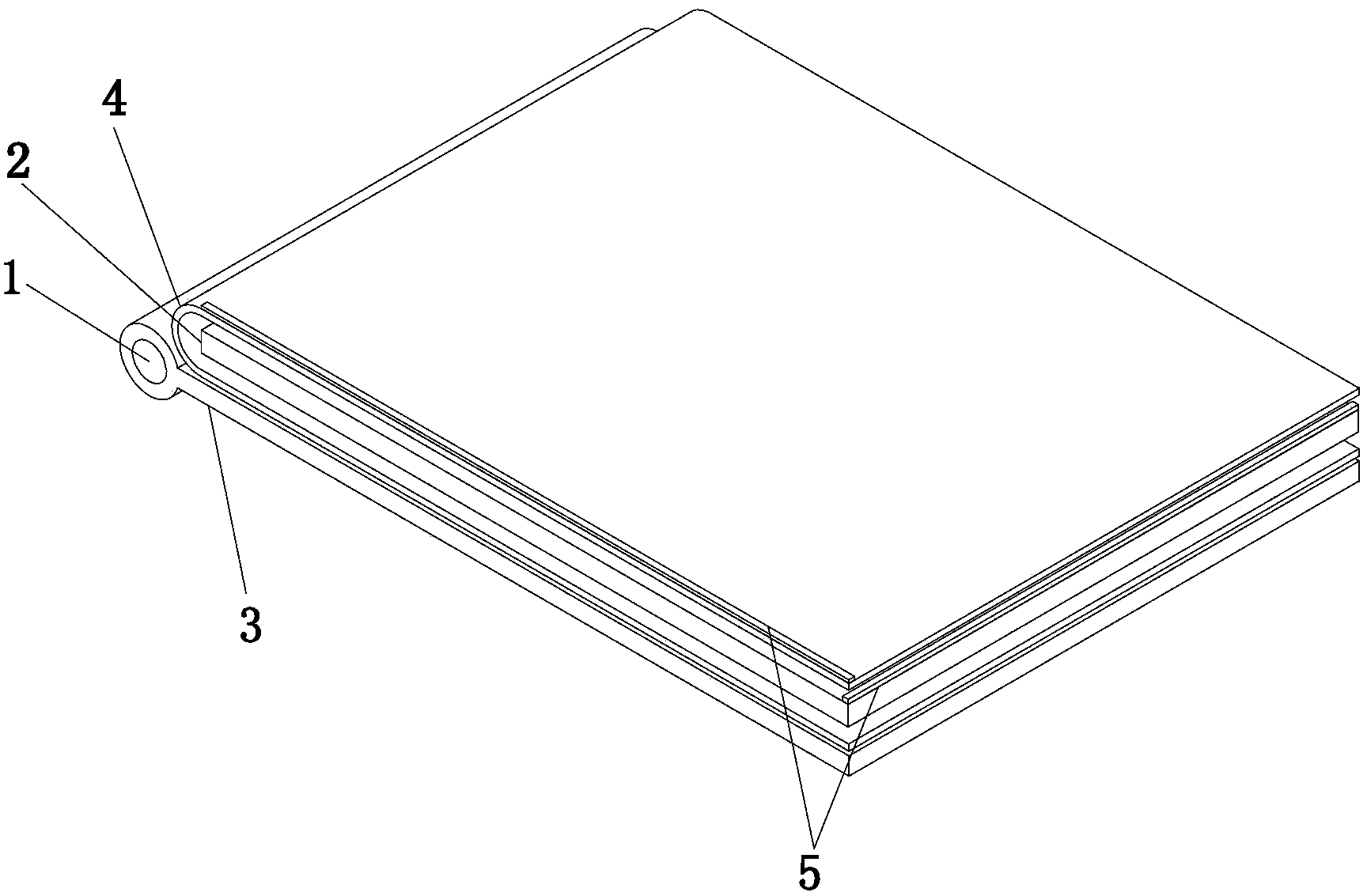

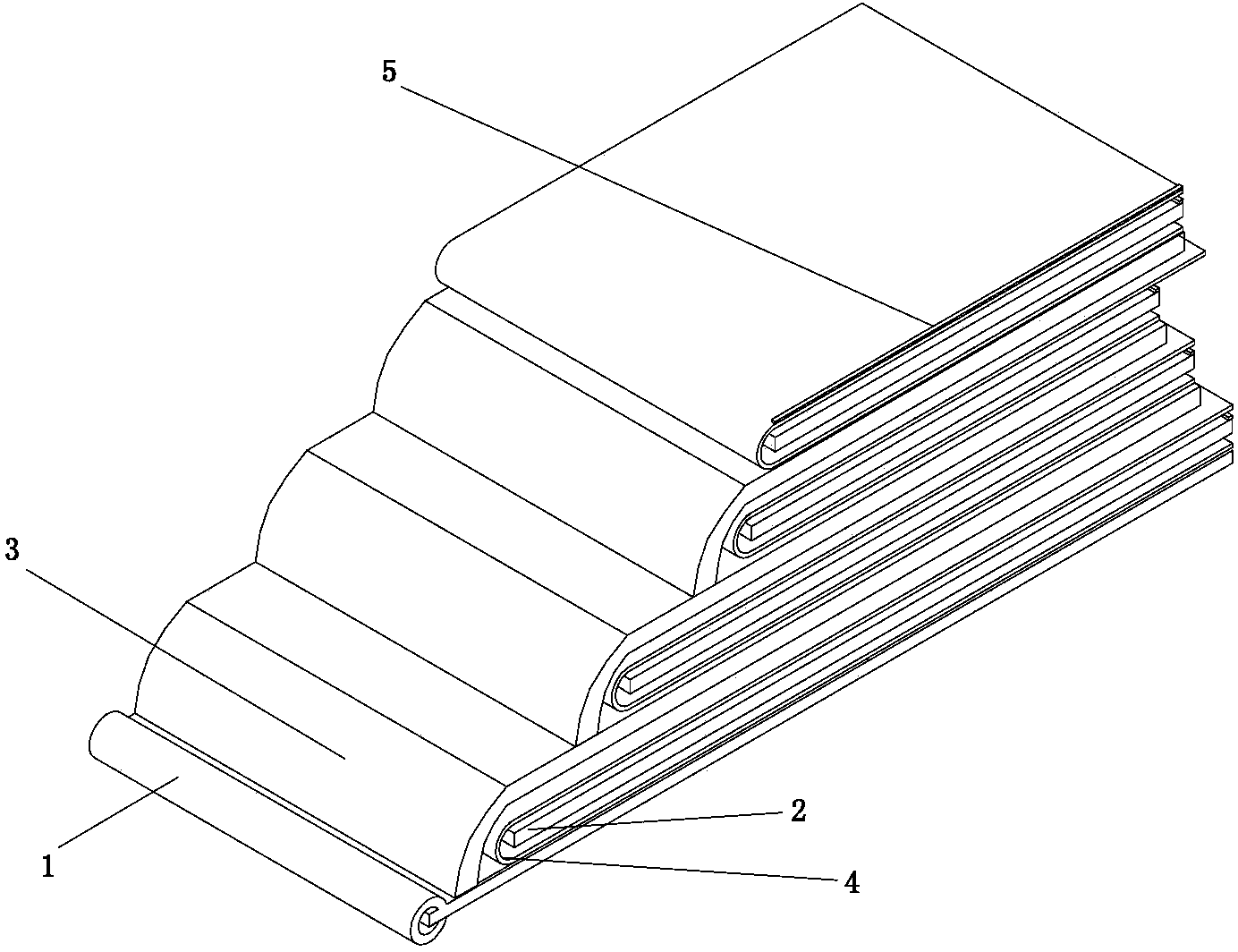

[0021] Example 1. The open product water flow channel step water inlet type coil membrane element is constituted as follows figure 1 and 2 As shown, it includes a central pipe 1, a water inlet screen 3, a water production screen 2 and a flat membrane 4. The water production screen 2 is installed between the flat membranes 4 folded in half, and one side of the end surface of the flat membrane 4 is The water production unit is sealed with the upper side of the water production screen 2 by sealant 5, and the water production unit is placed on the water supply screen 3, and then rolled around the center tube 1 and sealed to form a roll film 6 , the two ends of the roll film 6 are respectively provided with a water production collection sleeve 7 and a membrane end seal sleeve 8, the membrane end seal sleeve 8 is used to seal one end of the roll film 6, and the roll film 6 is provided with a membrane shell; the roll film 6 There is a water inlet slit 9 on it.

[0022] Such as i...

Embodiment 2

[0028] Example 2. The open product water flow channel step water inlet type coil membrane element is constituted as follows Figure 4 and 5 As shown, the structure of the roll film 6 is the same as in Embodiment 1, and conventional roll films on the market can also be used.

[0029]The membrane shell includes a cylindrical shell 10 and a water inlet 16 provided on the shell 10 (the water inlet 16 can be set at both ends of the non-center position), and the centers of the two ends of the shell 10 are respectively provided with concentrated water Collection port 15 and product water collection port 14, the two ends of the roll film 6 are respectively provided with a product water collection sleeve 7 and a membrane end sealing sleeve 8; Disk-shaped structure; the permeated water collection sleeve 7 is fixed on one end of the roll film 6 and sealed with the side wall of the roll film 6, the permeate water collection sleeve 7 and the end surface of the roll film 6 form a cavity b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com