Yarn for cell culture support and fabric comprising same

A technology of cell culture and yarn, which is applied in the direction of cell culture support/coating, special-purpose bioreactor/fermenter, tissue culture, etc., which can solve the problem of scaffold shape deformation, low cell survival rate, and weakened scaffold machinery Strength and other issues, to ensure mechanical strength, increase cell proliferation and survival, and improve cell proliferation and survival rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0046] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings, so that those skilled in the art of the present invention can easily implement them. The present invention can be realized in many different forms, and is not limited to the embodiments described here. In order to clarify the present invention, parts irrelevant to the description are omitted from the drawings, and the same reference numerals are assigned to the same or similar structural elements throughout the specification.

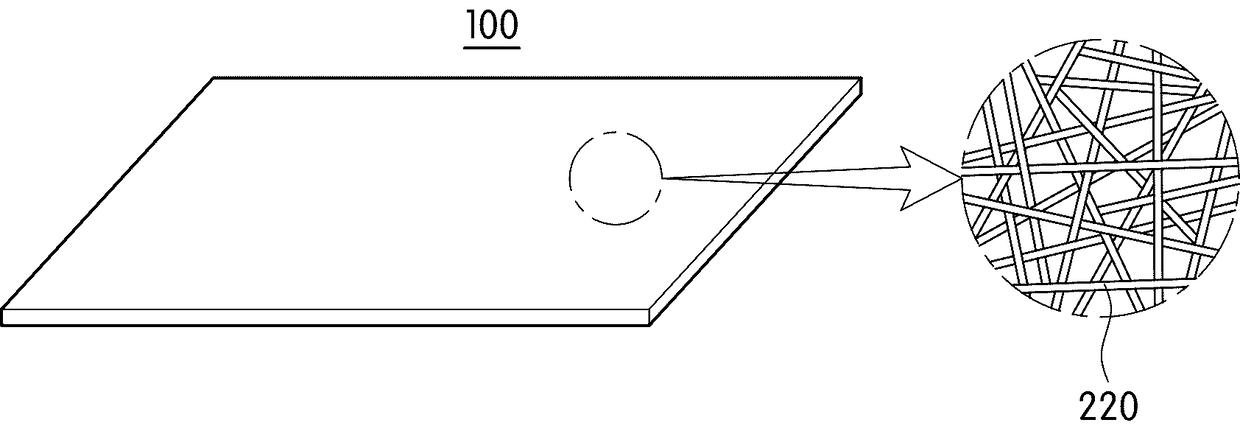

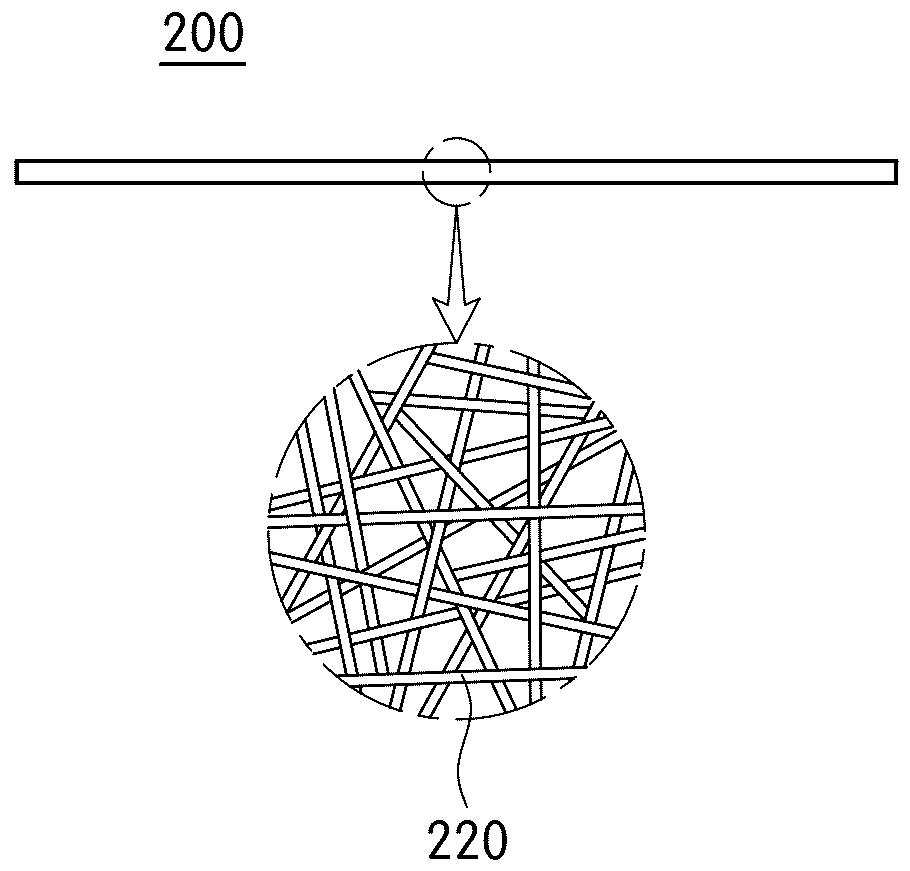

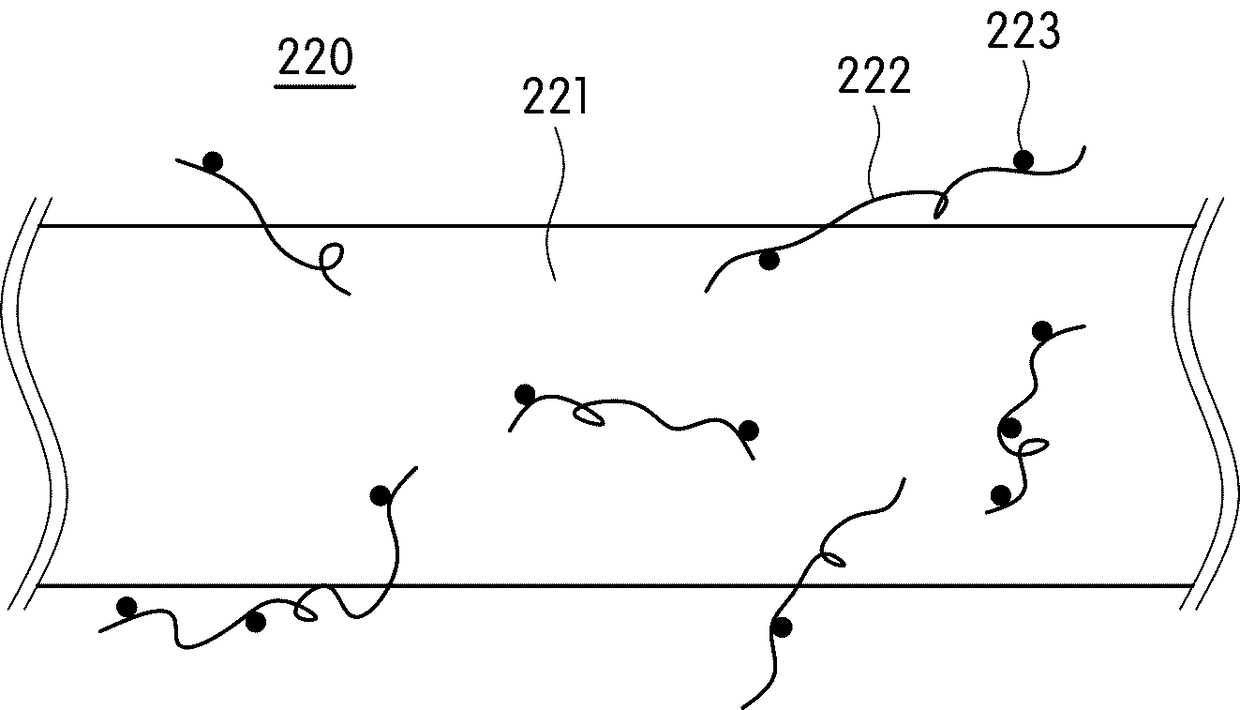

[0047] refer to figure 1 and figure 2 According to an embodiment of the present invention, the yarn for a cell culture scaffold includes a slit yarn 200 that cuts and compresses a nanofibrous web 100 including support fibers 220 at a predetermined width.

[0048] The aforementioned nanofibrous web 100 may have a three-dimensional network structure formed by at least one supporting fiber 220 .

[0049] Specifically, a thre...

Embodiment 1

[0104] First, to prepare a spinning solution, 12 g of polyvinylidene fluoride (Arkema, Kynar 761) as a fiber-forming component was dissolved in a 70:30 weight ratio at 80°C using a magnetic bar. dimethylacetamide and acetone in a mixed solvent of 88 g for 6 hours to prepare a mixed solution. Utilize the electrospinning device to electrospin the above-mentioned prepared spinning solution, as the electrospinning conditions, the applied voltage is 25KV, the distance between the current collector and the spinning port is 25cm, and the discharge volume is 0.05ml / hole, at RH 65 Under an environment of 30° C., electrospinning was performed to obtain a nanofibrous web formed of supporting fibers having the diameter distribution shown in Table 1 below. The obtained nanofibrous web was calendered twice at a temperature of 130°C and a pressure of 4kPa, such as Image 6 As shown in part (b), a three-dimensional network structure with a basis weight of 10 g / m 2 , a compressed nanofibrous...

Embodiment 2~12

[0107] Prepared in the same manner as in Example 1, but by adjusting the basis weight / thickness of the nanofibrous web before compression and the strength during compression to make the compressed nanofibers have the basis weight and thickness as shown in Table 3 below, thus obtaining the following The slitting yarns shown in Table 3 were described.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com