A supercapacitor have more excellent performance under ultra-low temperature condition and preparation method thereof

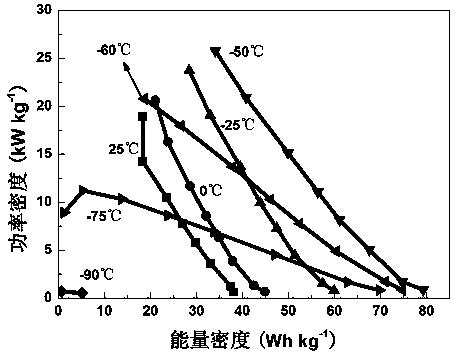

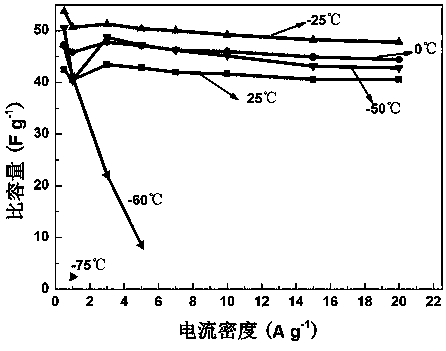

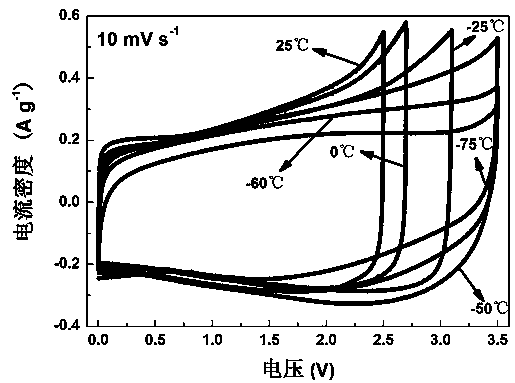

A supercapacitor and ultra-low temperature technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, hybrid capacitor electrolytes, etc., can solve the constraints on the application prospects of supercapacitors, low specific capacity and energy density, and can only reach -40°C and other issues, to achieve the effect of easy industrial application, high added value and best performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 A supercapacitor with better performance under ultra-low temperature conditions is composed of a casing, a positive electrode sheet placed in the casing, a negative electrode sheet, a diaphragm between the positive and negative electrode sheets, and an electrolyte; the positive electrode sheet and the Both the negative electrode sheet and the separator are suspended in the electrolyte. The electrolyte is composed of ionic liquid, organic solvent and organic co-solvent, the concentration of the electrolyte is 1M; the volume ratio of organic solvent and organic co-solvent is 3:1.

[0037] Wherein: the cation of the ionic liquid is 1-ethyl-3-methylimidazolium ion, and the anion is tetrafluoroborate. The organic solvent is acetonitrile. The organic co-solvent was methyl acetate.

[0038] The positive electrode sheet or the negative electrode sheet is a nickel foam sheet coated with a mixture of carbon material, conductive agent and binder; the carbon material is...

Embodiment 2

[0048] Example 2 A supercapacitor with better performance under ultra-low temperature conditions is composed of a casing, a positive electrode sheet placed in the casing, a negative electrode sheet, a diaphragm between the positive and negative electrode sheets, and an electrolyte; the positive electrode sheet and the Both the negative electrode sheet and the separator are suspended in the electrolyte. The electrolyte is composed of ionic liquid, organic solvent and organic co-solvent, the concentration of electrolyte is 2M; the volume ratio of organic solvent and organic co-solvent is 2:1.

[0049] Wherein: the cation of the ionic liquid is 1-butyl-3-methylimidazolium ion, and the anion is hexafluorophosphate. The organic solvent is propylene carbonate. The organic co-solvent was methyl formate.

[0050] The positive electrode sheet or the negative electrode sheet is a stainless steel sheet coated with a mixture of carbon material, conductive agent and binder; the carbon ma...

Embodiment 3

[0055] Example 3 A supercapacitor with better performance under ultra-low temperature conditions is composed of a casing, a positive electrode sheet placed in the casing, a negative electrode sheet, a diaphragm between the positive and negative electrode sheets, and an electrolyte; the positive electrode sheet and the Both the negative electrode sheet and the separator are suspended in the electrolyte. The electrolyte is composed of ionic liquid, organic solvent and organic co-solvent, the concentration of the electrolyte is 1.5M; the volume ratio of organic solvent and organic co-solvent is 1:1.

[0056] Wherein: the cation of the ionic liquid is N-methylbutylpyrrolidinium ion, the anion is bistrifluoromethanesulfonimide ion, the organic solvent is N,N-dimethylformamide, and the organic co-solvent is absolute ethanol.

[0057] The positive electrode sheet or the negative electrode sheet is an aluminum foil sheet coated with a mixture of carbon material, conductive agent and b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com