A supercapacitor electrode material and a preparation method thereof

A technology for supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors. It can solve the problems of low conductivity, unfavorable electrolyte diffusion and electron transmission, etc., and achieve low cost, good capacitance performance and Effects of cycling stability, diffusion, and electrical performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In 39-45mmol of p-aminobenzoic acid, add 60ml of aqueous solution containing 45-51mmol of NaOH and 20ml of dioxane solution containing 9mmol of cyanuric chloride under stirring conditions, and heat to reflux at 105°C for 10-12h. After naturally cooling to room temperature, filter with suction and wash the product with water. Then adjust the pH to 1 with HCl, and dry in vacuum at 80°C to obtain light yellow ligand H 3 TATAB. According to Co(COO) 2 .6H 2 O and H 3 The molar ratio of TATAB is 1:2 and put into the reaction kettle, add ethanol and N,N-dimethylformamide with a volume ratio of 1:1, and react at 120°C for 48h. The obtained product was suction filtered, washed with ethanol and dried in vacuum to obtain the purple electrode material Co-MOF-120. The electrochemical performance test of the material shows that the charge transfer resistance of the material is 0.584Ω, which has a small equivalent series resistance value. The cyclic voltammetry curve is rectangu...

Embodiment 2

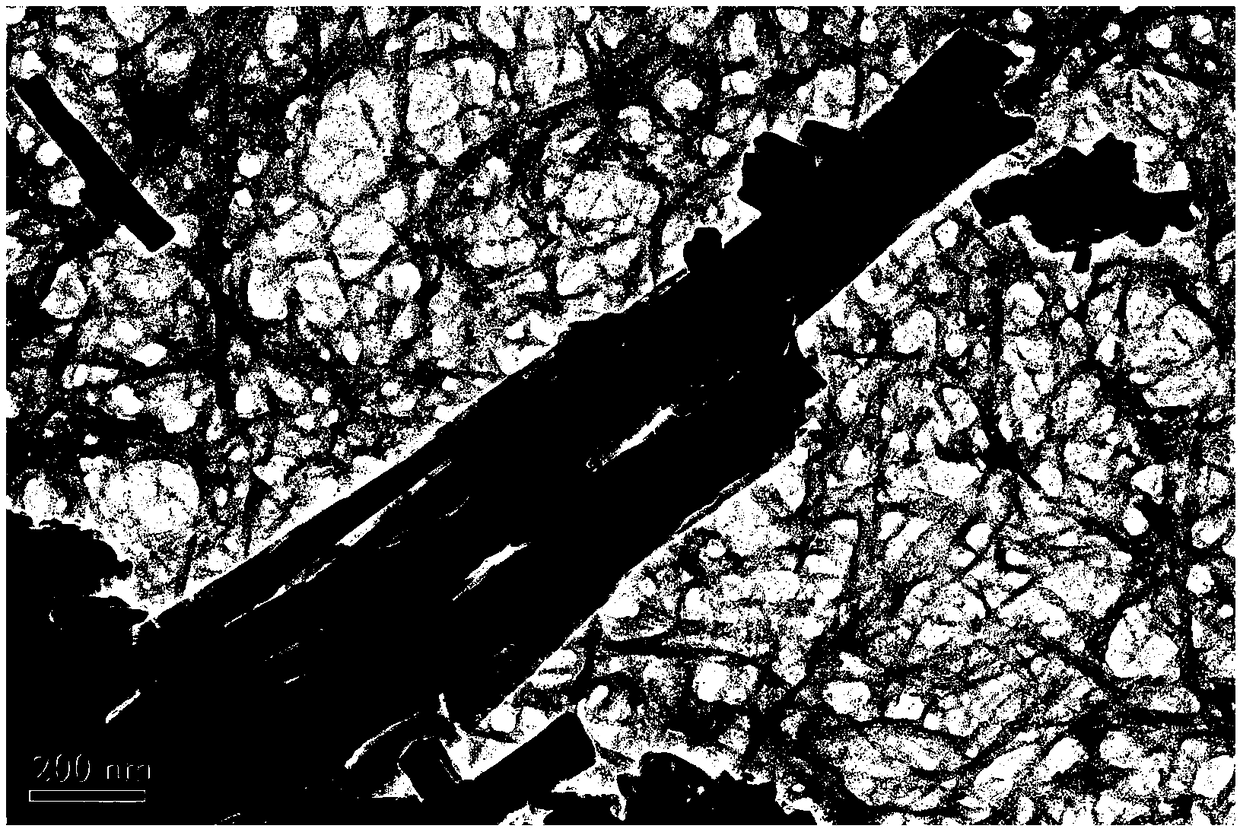

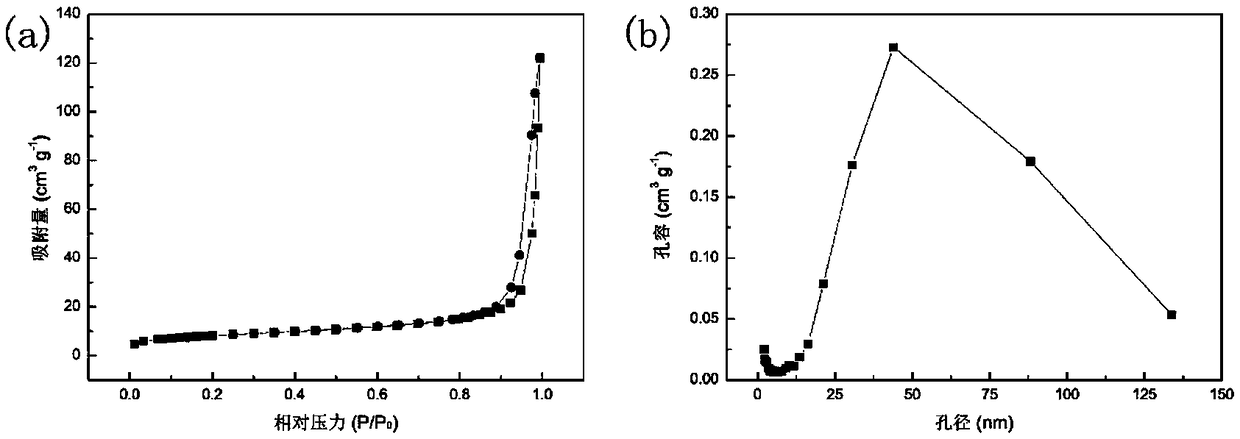

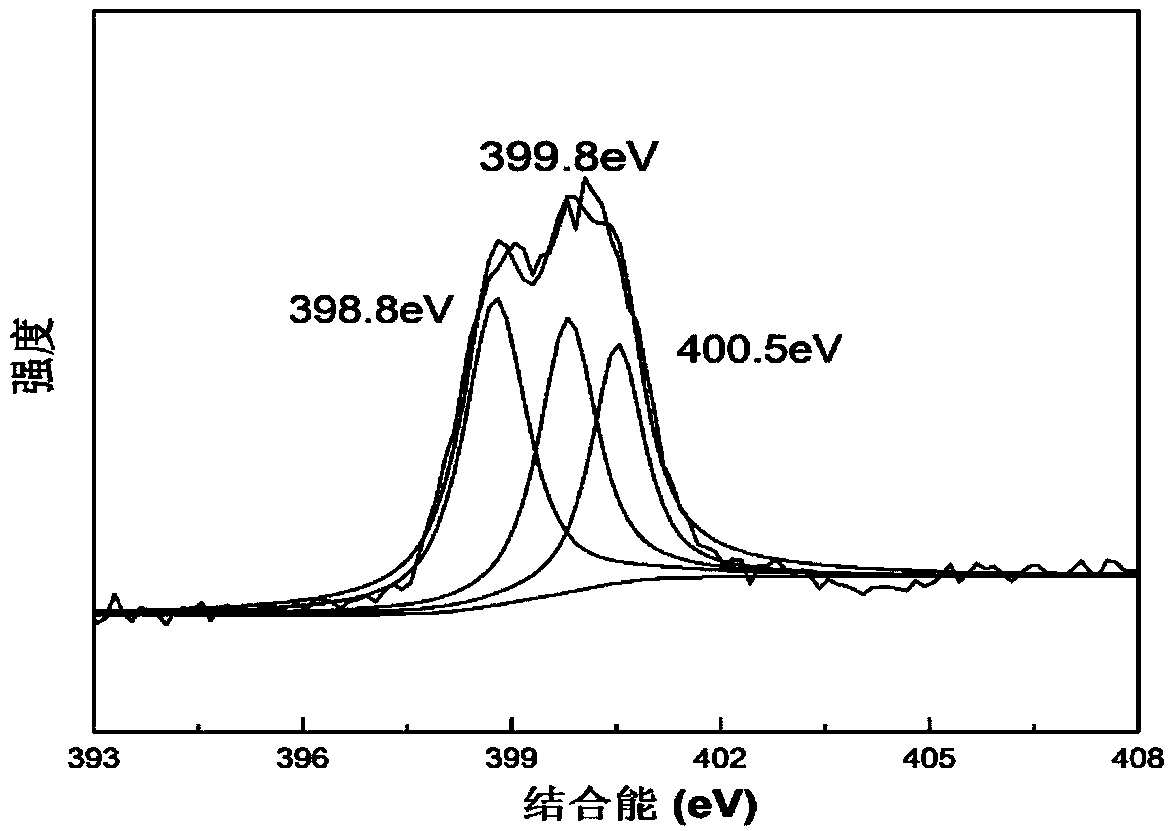

[0033] The synthesis of the ligand is the same as in Example 1. According to Co(COO) 2 .6H 2 O and H 3 The molar ratio of TATAB is 1:2 and put into the reaction kettle, add ethanol and N,N-dimethylformamide with a volume ratio of 1:1, and react at 140°C for 48h. The obtained product was suction filtered, washed with ethanol and dried in vacuum to obtain the purple electrode material Co-MOF-140-1:2. The electrochemical performance test of the material shows that the material has a charge transfer resistance of 0.474Ω, a small equivalent series resistance value and excellent diffusion performance. Specific as Figure 1 to Figure 6 shown. Transmission electron microscope pictures as figure 1 As shown, it can be seen from the figure that the shape of the Co-MOF-140-1:2 material is a mixed structure of nano needles and rods, which can provide a large number of ion exchange channels and accelerate the entry of ions in the electrolyte into the electrode. N 2 The adsorption-de...

Embodiment 3

[0035] The synthesis of the ligand is the same as in Example 1. According to Co(COO) 2 .6H 2 O and H 3 The molar ratio of TATAB is 1:2 and put into the reaction kettle, add ethanol and N,N-dimethylformamide with a volume ratio of 1:1, and react at 160°C for 48h. The obtained product was suction filtered, washed with ethanol and dried in vacuum to obtain the purple electrode material Co-MOF-160. The electrochemical performance test of the material shows that the charge transfer resistance of the material is 0.645Ω, which has a small equivalent series resistance value. The cyclic voltammetry curve is rectangular, indicating that the charge storage is dominated by electric double layer capacitance. Calculated from the charge-discharge curve, when the current density is 0.5A·g -1 , the specific capacitance value of the material is 225.2F·g -1 , with excellent electrochemical performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com